AT traction electric power supply system of 27.5KV AC electrification railway

A technology for traction power supply systems and electrified railways. It is applied in power lines, transportation and packaging, and vehicle components. It can solve the problems of difficult transformer manufacturing, increased traction network impedance, and increased cost, so as to facilitate daily maintenance and repair. The effect of reducing the number of projects and reducing the project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

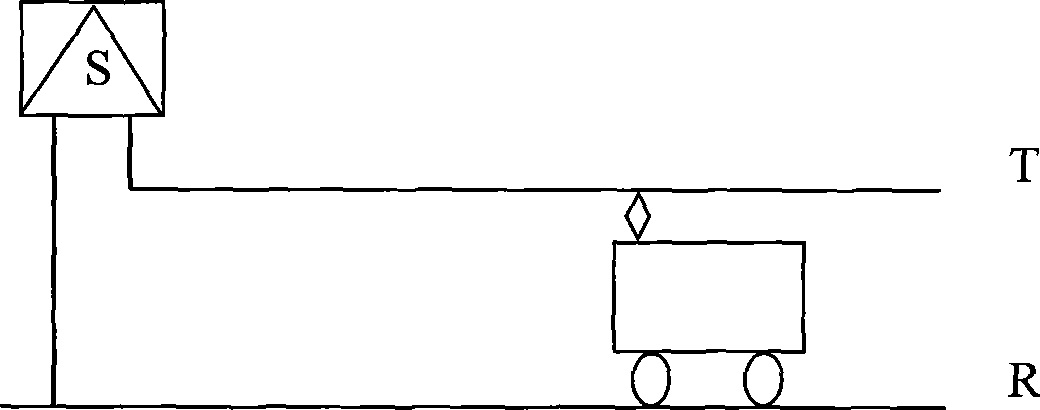

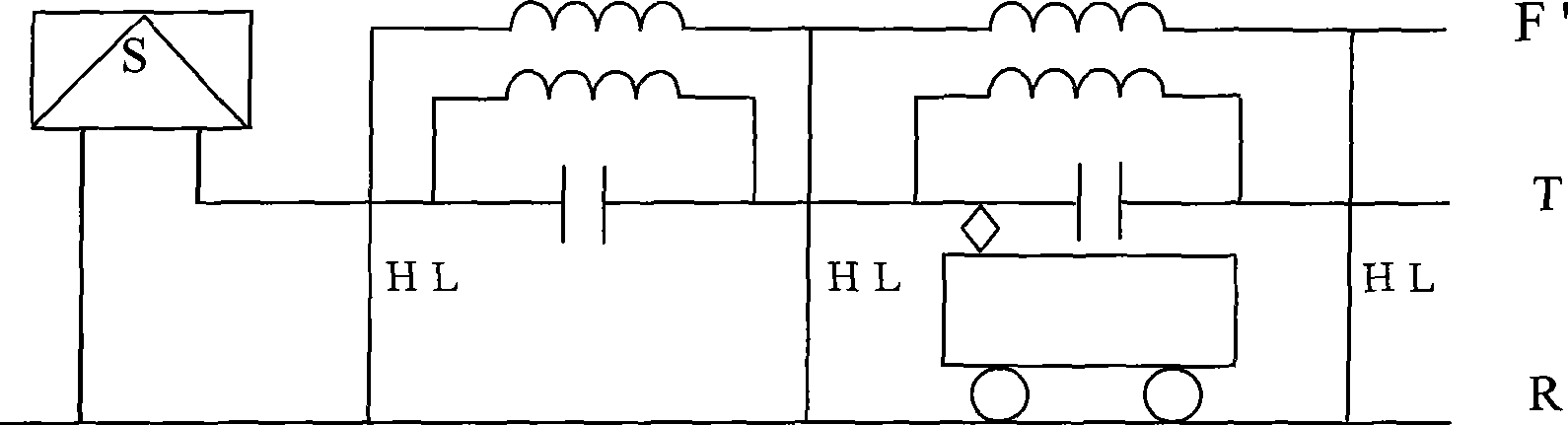

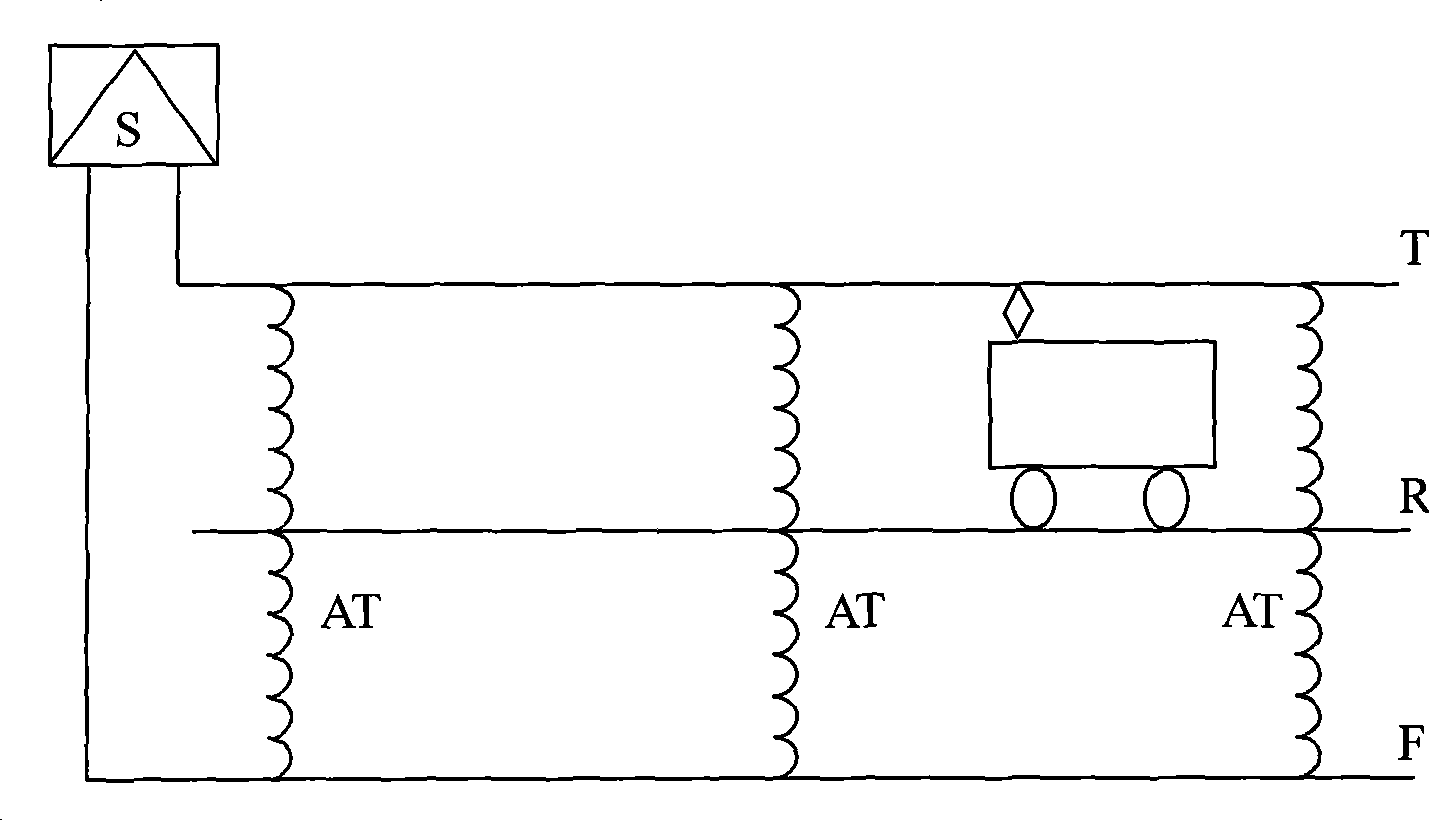

[0027] Figure 4 As shown, a specific embodiment of the present invention is a 27.5KV AC electrified railway AT traction power supply system, which consists of:

[0028] The output voltage of the traction transformer S in the traction substation is 27.5kV. One output terminal M of the traction transformer S is connected to the rail R, and the other output terminal N is connected to the positive feeder F of the railway traction network;

[0029] The railway traction network is equipped with an autotransformer AT with a transformation ratio of 2:1 every 10-20km. One end a of the autotransformer AT is connected to the railway contact line T, the middle point o is connected to the rail R, and the other end b is connected to the railway traction line. The positive feeder F of the network is connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com