Smoke discharging pipeline

A technology of smoke exhaust pipes and gas pipes, which is applied in the direction of exhaust gas exhaust devices, combustion product treatment, combustion methods, etc., can solve the problems of inconvenience for residents in the use area, increase labor intensity and difficulty of installation or maintenance workers, and high manufacturing costs. Achieve the effects of reducing the intensity of installation and maintenance, facilitating promotion and application, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

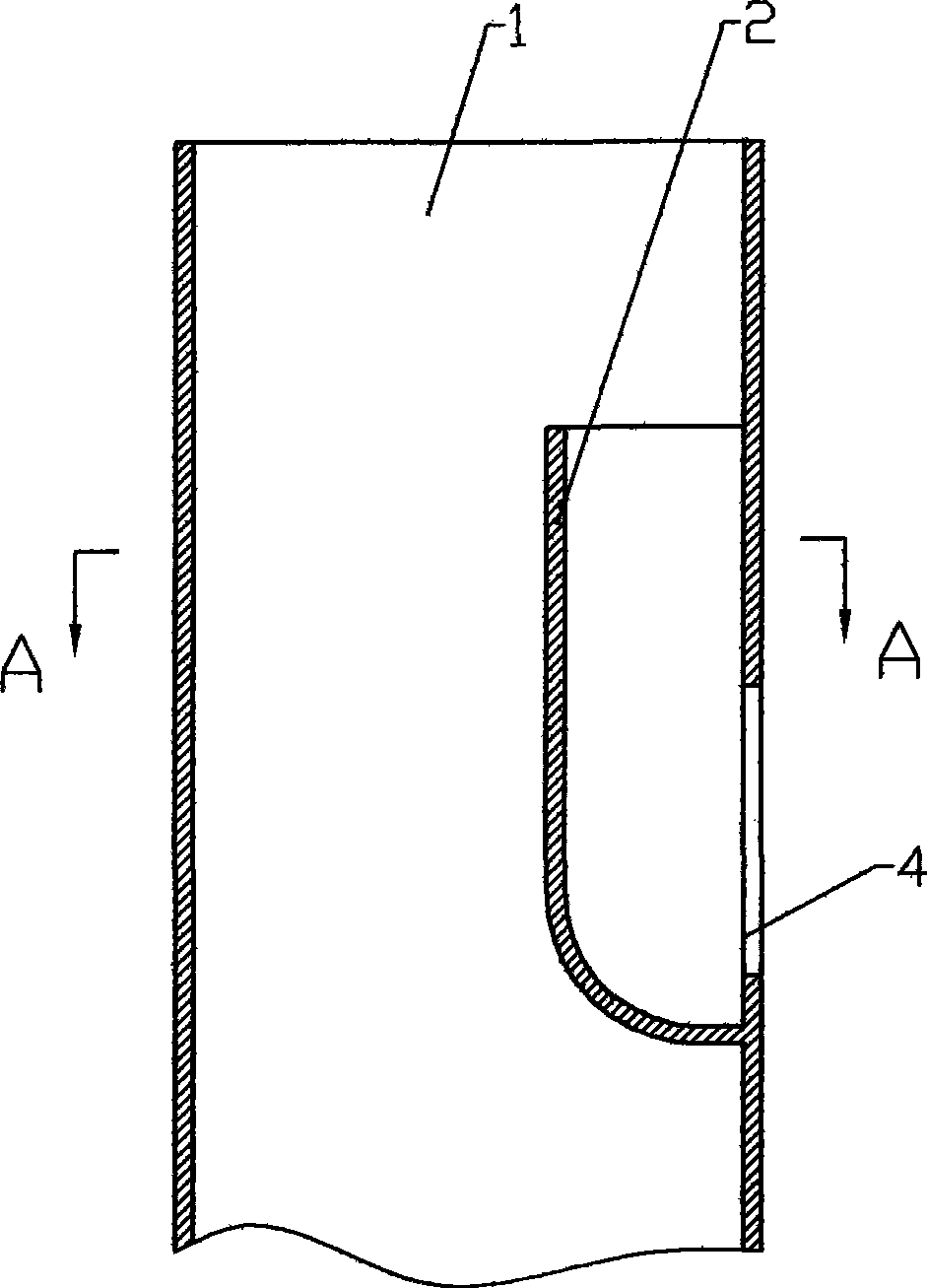

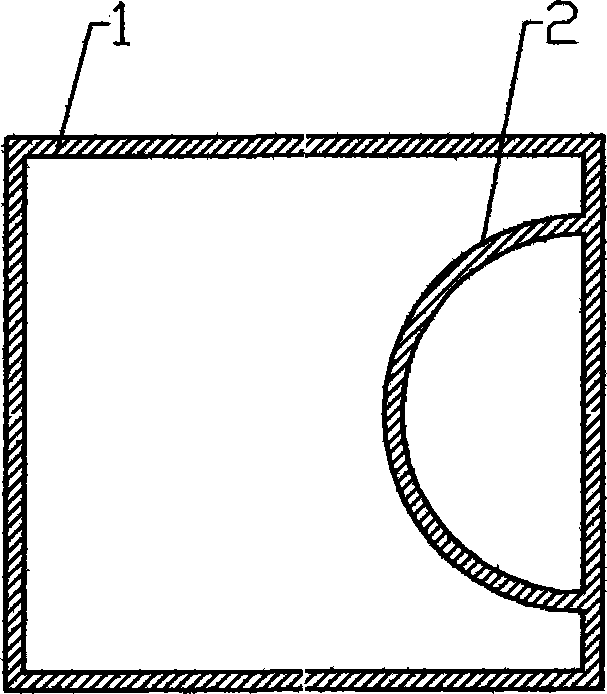

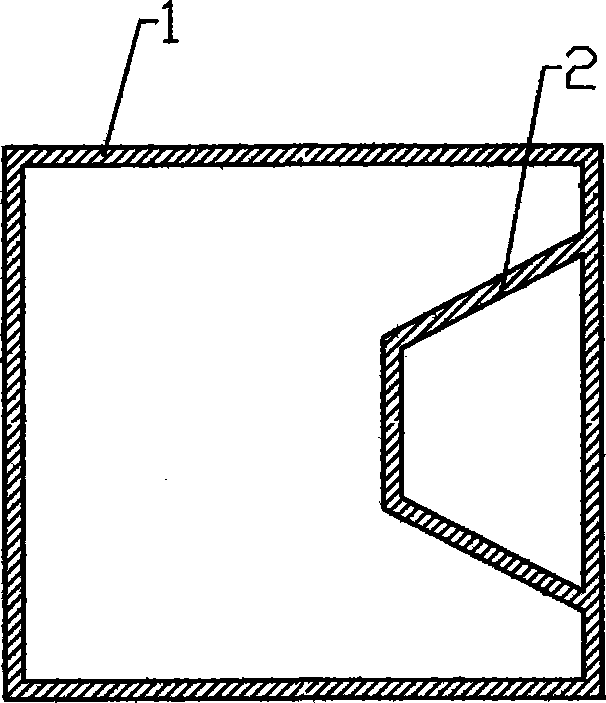

[0016] Such as figure 1 As shown, a smoke exhaust pipe includes a smoke exhaust pipe body 1, at least one air inlet 4 is provided on the smoke exhaust pipe body 1, and each air inlet 4 is provided with an exhaust pipe 2 to assist exhaust The pipe 2 is located inside the pipe body 1. The drainage aid pipe 2 is integrated with the pipe body 1. The drainage aid pipe 2 and the inner wall of the pipe body 1 form a flue gas outlet pipe that is closed at the lower end and has a diameter smaller than the inner diameter of the pipe body 1, namely The exhaust aid pipe 2 and the pipe body 1 are formed in the same mold at one time, that is, during casting, a structure of casting the exhaust aid pipe 2 is added to the casting mold, so that after the casting is completed, the exhaust aid pipe 2 and the smoke exhaust pipe 1 become one.

[0017] During the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com