Calibration apparatus for six-dimension heavy force sensor

A calibration device and force sensor technology, applied in the direction of measurement device, instrument, force/torque/work measuring instrument calibration/test, etc., can solve the problem of low loading accuracy, compact structure, and can not meet the calibration requirements of six-dimensional force sensor and other problems, to achieve the effect of high precision and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

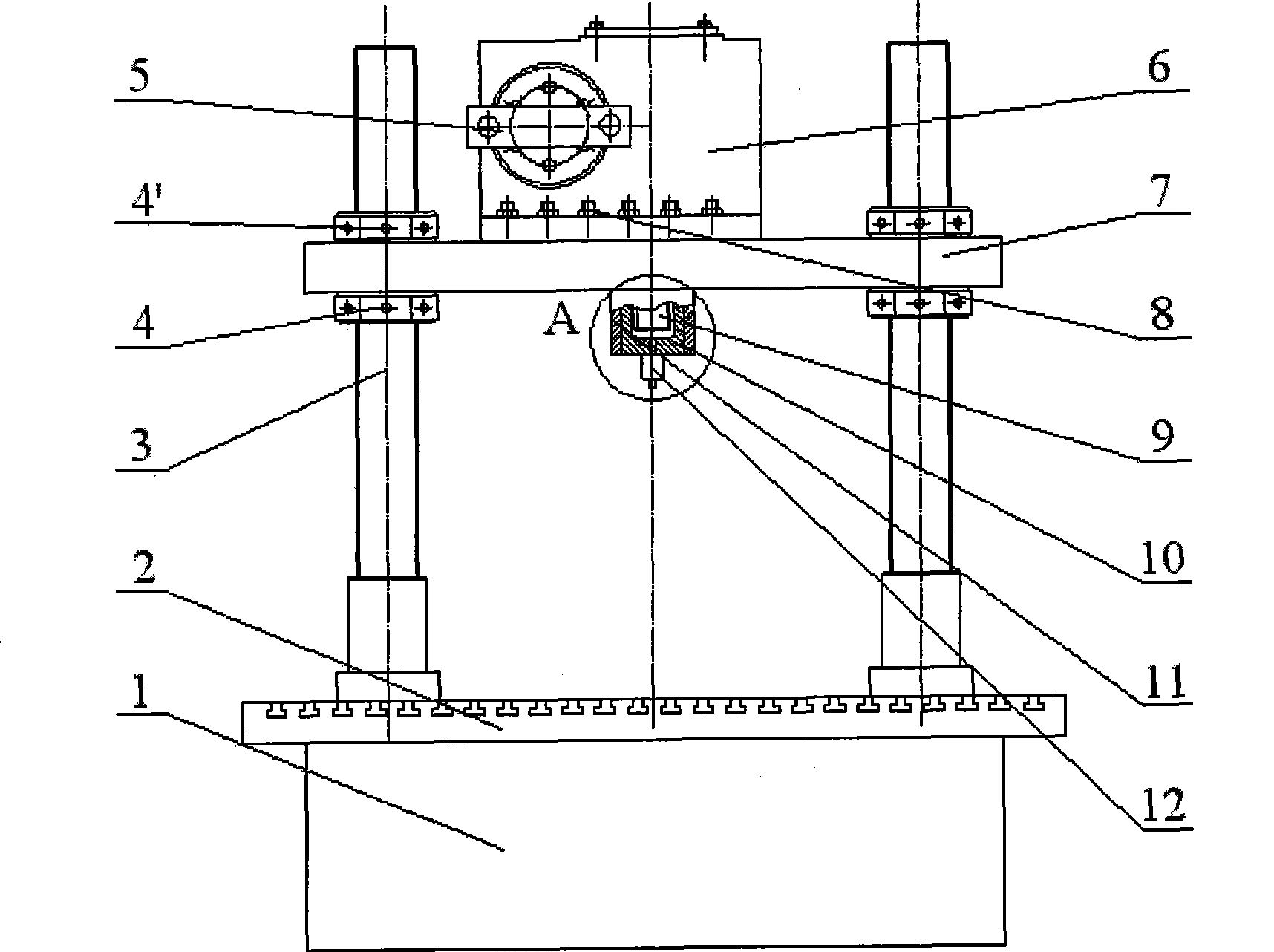

[0012] The concrete implementation of the present invention is described in detail in conjunction with accompanying drawing and technical scheme:

[0013] 1) The installation of the large force loading mechanism and the calibrated mechanism

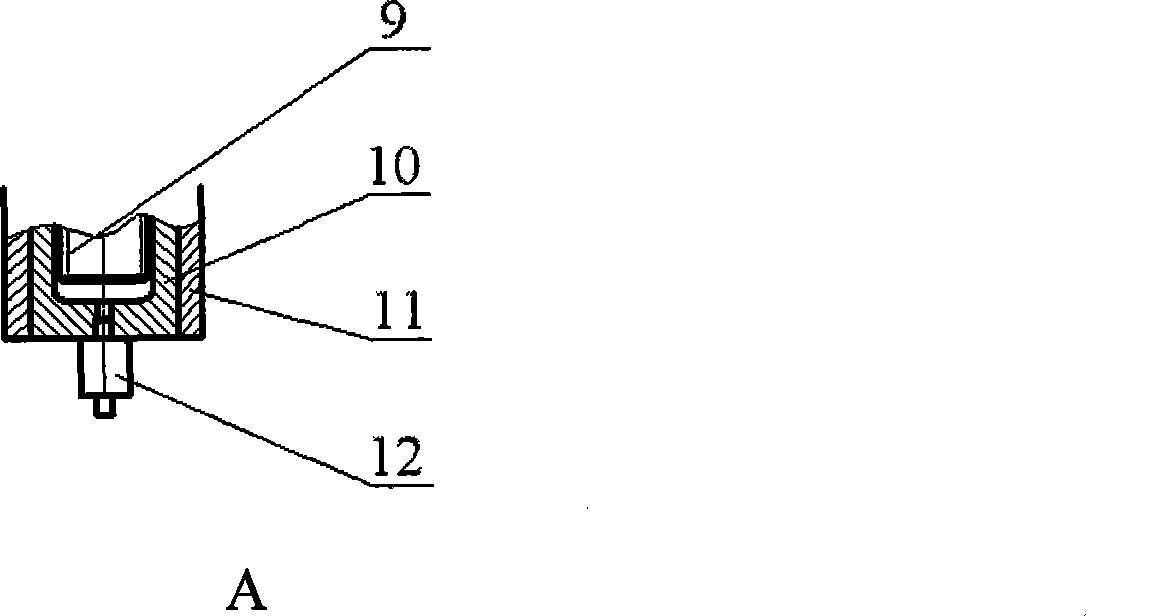

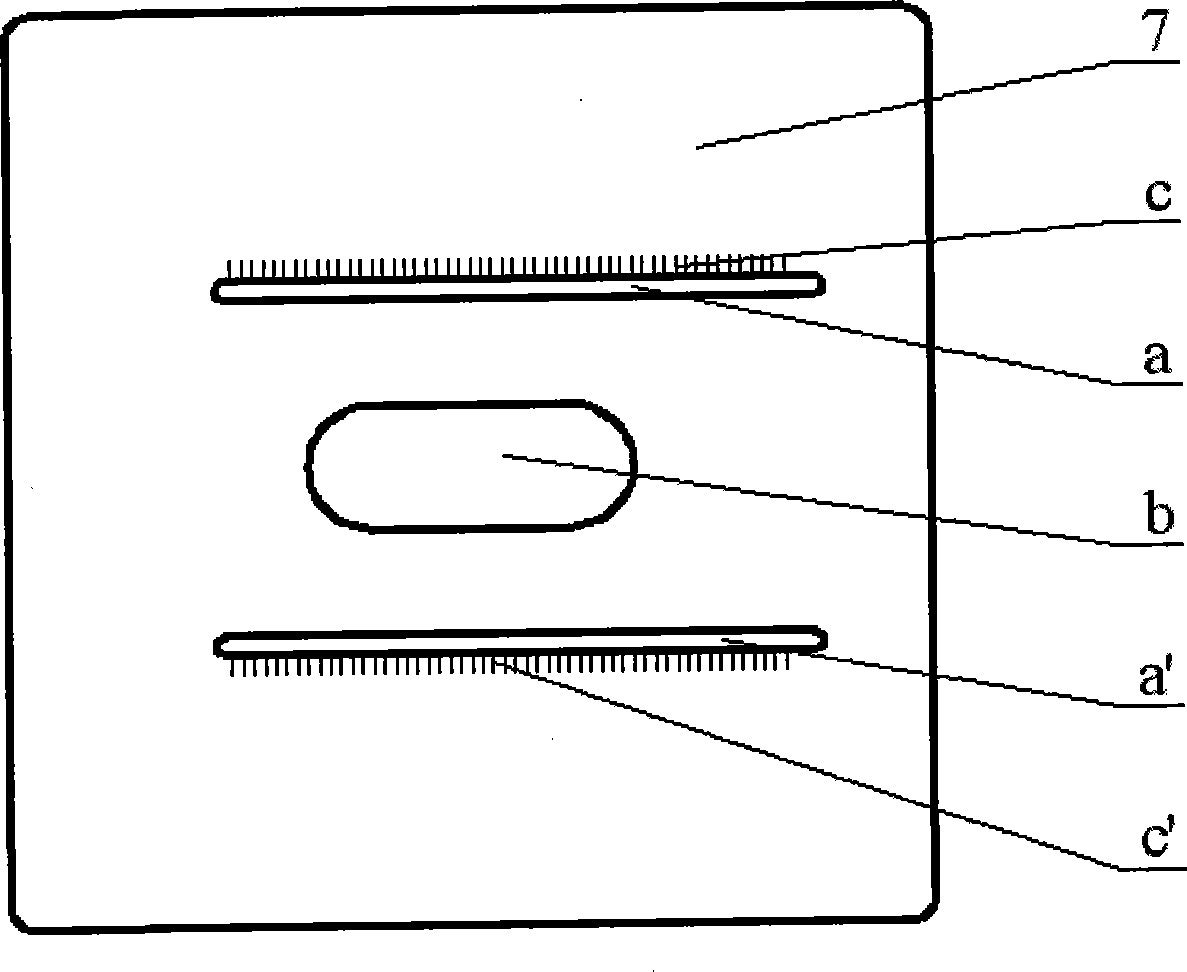

[0014] Install the upper support plate 7 on the four uprights 3, and fix it with eight up and down lifting nuts 4, 4', place the high force value loading mechanism 6 on the upper surface of the upper support plate 7, and the high force value load mechanism 6 outputs The end passes through the central long hole b of the upper supporting plate 7, the output end of the high force loading mechanism 7 can translate left and right in the central long hole b, and is adjusted by the scale d on the high force loading mechanism 6 and the scale c of the upper supporting plate 7 The left and right positions of the great value loading mechanism 6 make the axis of the standard unidirectional force sensor 12 connected to the output end of the great valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com