Reverse polarity plasma arc robot additive manufacturing system and its realization method

A technology of additive manufacturing and plasma arc, which is used in plasma, plasma welding equipment, manufacturing tools, etc., to achieve the effect of stable wire feeding process, high precision and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] It should be noted that the embodiments in the present application and the features in the embodiments may be combined with each other without conflict, and the present application will be further described in detail below with reference to the accompanying drawings and specific embodiments.

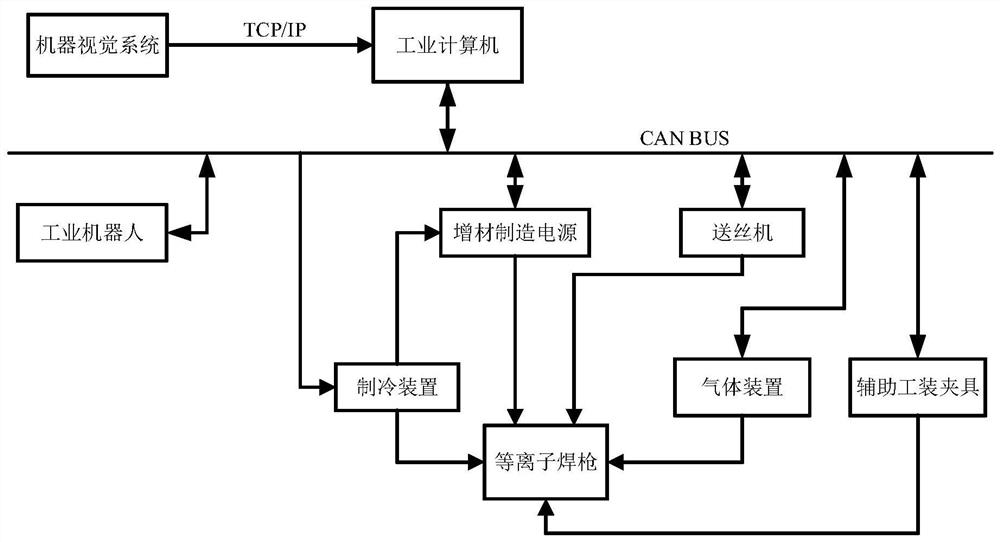

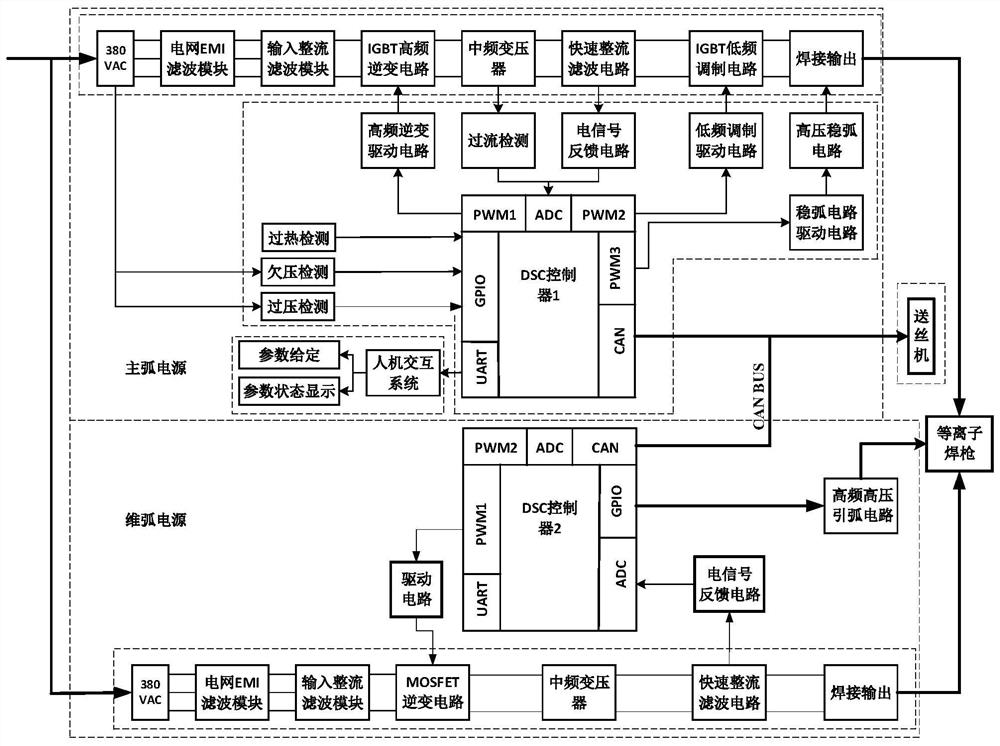

[0061] like figure 1 As shown, the present invention provides a reverse polarity plasma arc robotic additive manufacturing system, including an industrial robot, an additive manufacturing power source, a wire feeder, a machine vision system, an industrial computer, a plasma torch, a refrigeration device, a gas device, and Auxiliary fixtures, etc.; the industrial robot, additive manufacturing power supply, wire feeder, refrigeration device, gas device, and auxiliary fixture are all connected to the industrial computer through CAN BUS; the machine vision system is connected to the industrial computer through TCP / IP The refrigeration device is also connected with the additive manufac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com