Prevulcanized tread and recapped tire using the same

A technology of precured tires and vulcanized treads, which is applied to tire treads/tread patterns, tire parts, tires, etc., and can solve problems such as wet performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

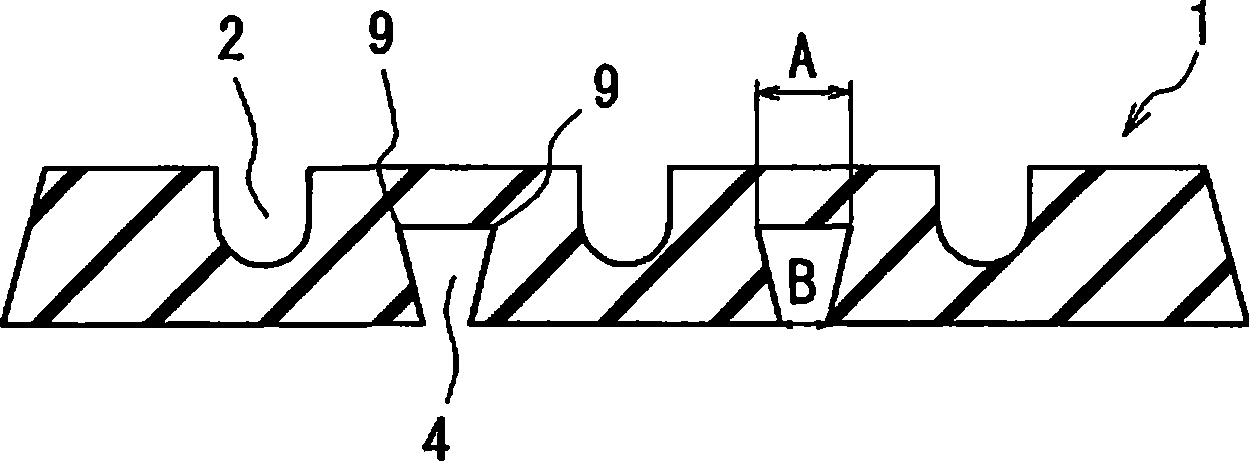

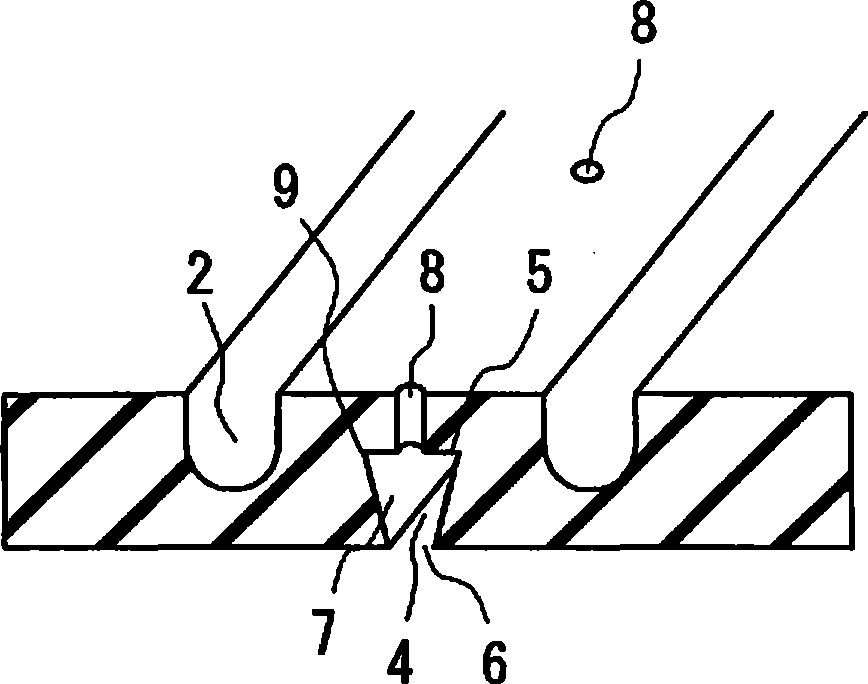

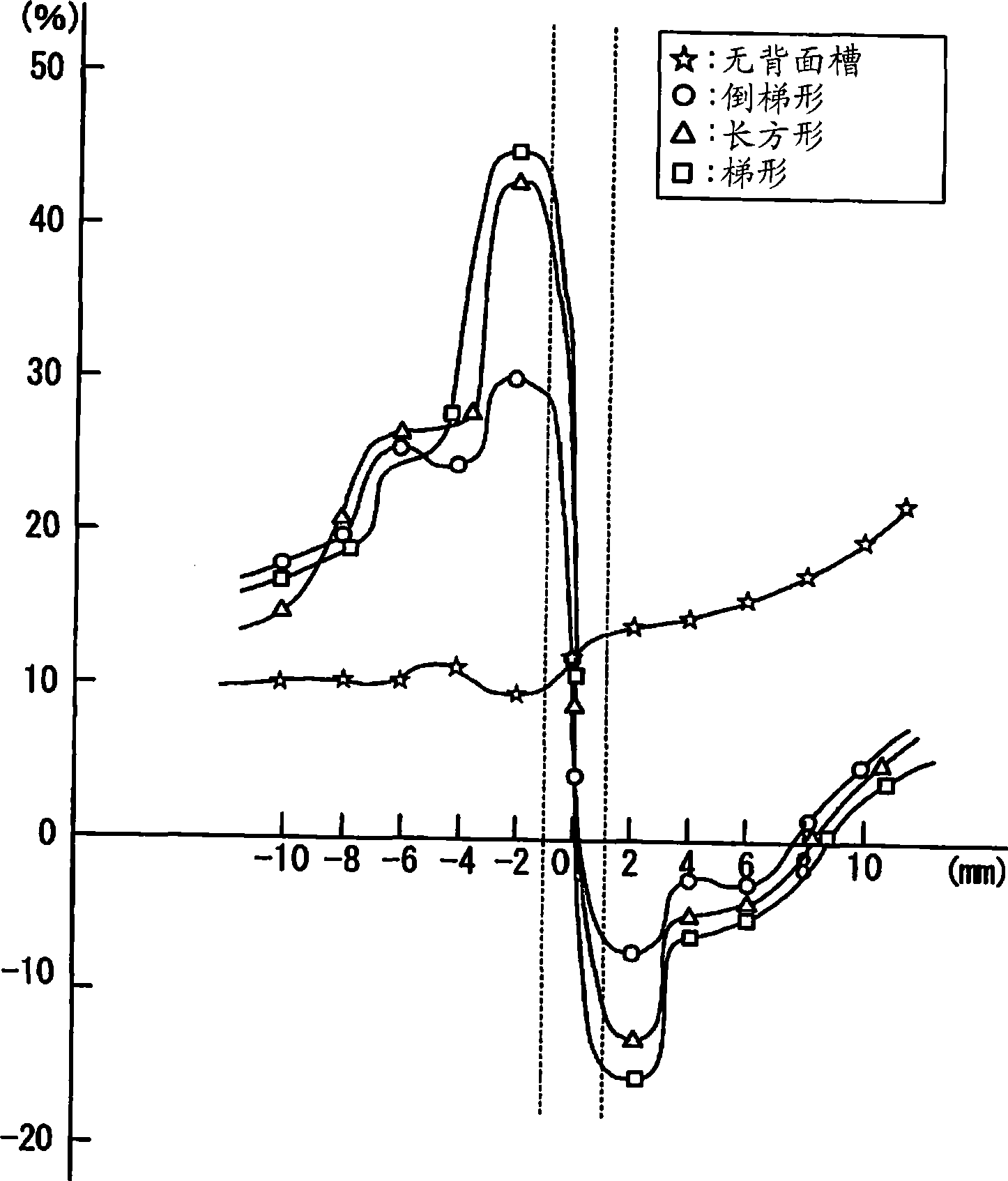

[0054] A precured tread having the following structure was attached to the base tire to form a retreaded tire with a tire size of 11R22.5: the precured tread was provided with three circumferential grooves and two back grooves, the circumferential grooves having a groove width of 13.0 mm, the groove width of the back groove at the bottom is 4.0 mm, and the ratio of the width of the back groove at the opening to the width of the back groove at the bottom is constant or not. Three tires were prepared for each groove width ratio. Each of the above test tires was mounted on a rim having a size of 8.25 to form a tire / rim assembly to which an air pressure (relative pressure) of 700 kPa was applied. Under the conditions of a tire load of 2500 kN and a running speed of 60 km / h, a test of a running distance of 20,000 km was performed on each tire / rim assembly on a drum testing machine. Each tire after running was visually observed to confirm the presence or absence of peeling of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com