Method for improving loop heating control precision and reliability by 1wire temperature sensor

A temperature sensor and heating control technology, applied in temperature control, temperature control using electric mode, non-electric variable control, etc., can solve the problems of difficult judgment of sensor failure, poor reliability, poor circuit anti-interference ability, etc. Interference and failure identification function, overcome transmission error, improve reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

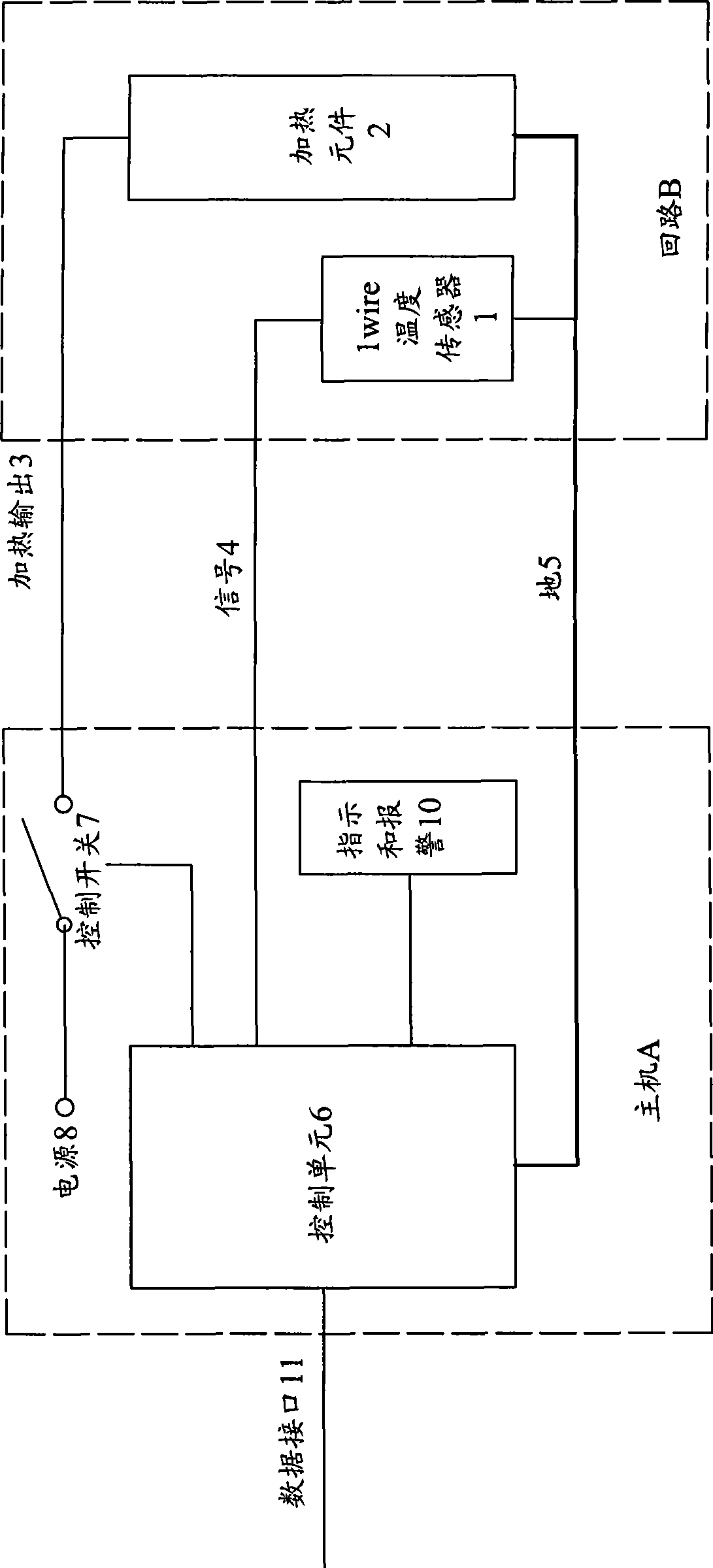

[0013] Below, the present invention will be described in detail in conjunction with the accompanying drawings.

[0014] Implement the equipment that the present invention is applied in the figure and have: select DS18B20 in the 1wire series as temperature sensor 1, and choose the typical detection point in the circuit as the temperature measurement point of temperature sensor 1; Heating element 2 can adopt heating rod, heating wire Or PTC and other components, the heating power is selected according to the size of the loop 3 and the heat dissipation, so as to ensure that the heating power can meet the predetermined temperature in the required preheating time; the control unit 6 can use AT89C51, PIC16F84 or other controllers; the control switch 7 MOSFETs or relays can be used; the indication and alarm 10 can be realized by using the output pins of the controller to drive LEDs and buzzers; the data interface 11 can be realized by using the serial interface of the controller. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com