Expansion pulling device for steel framed side wallboard of carriage

A side wall panel and steel structure technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high production cost, different degrees of tightness of side wall panels, and reduce production Cost, steel plate material saving, consistent tightness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described in detail below with reference to the accompanying drawings and examples. However, the invention is not limited to the examples given.

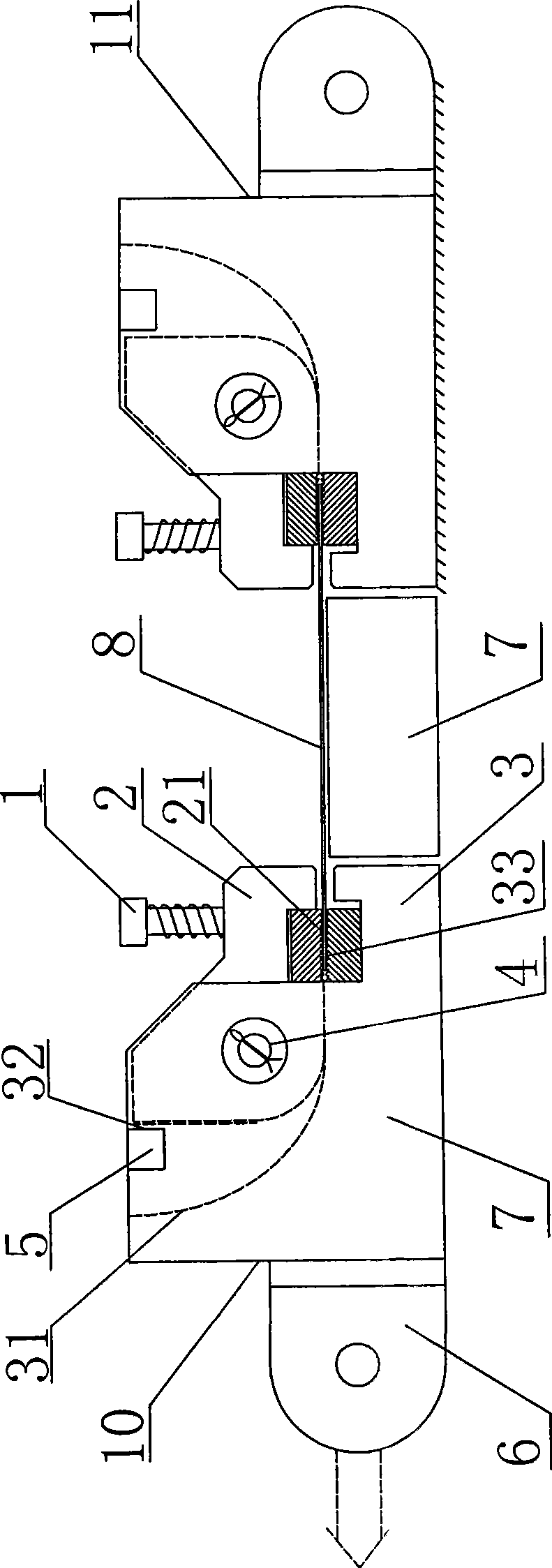

[0008] Such as figure 1 As shown, the steel structure side wall panel tensioning device of the railway passenger car of the present invention comprises positioning chucks 11 and moving chucks 10 distributed symmetrically and equidistantly at both ends of the side wall panel 8 in the longitudinal direction. , an upper clamping block 2, a rotating shaft 4, a stopper 5, a clamping screw 1, and a pull hook 6. The lower clamping block 3 has an upper clamping block rotation groove 31 and a block groove 32 perpendicular to the rotation groove. The upper clamping block 2 and the lower clamping block 3 are rotationally connected by the rotating shaft 4, the stopper 5 is located in the block groove 32 of the lower clamping block, the clamping screw 1 is longitudinally threaded with the jaw end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com