Embedded type ferrule sealing structure

A sealing structure, embedded technology, applied in the direction of sealing surface connection, pipe/pipe joint/pipe fitting, through components, etc., can solve the problem of parallel pipeline intensive installation, processing technology problems, limited application scope, etc. problem, to achieve the effect of good performance of repeated assembly and disassembly, compact structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the drawings and embodiments.

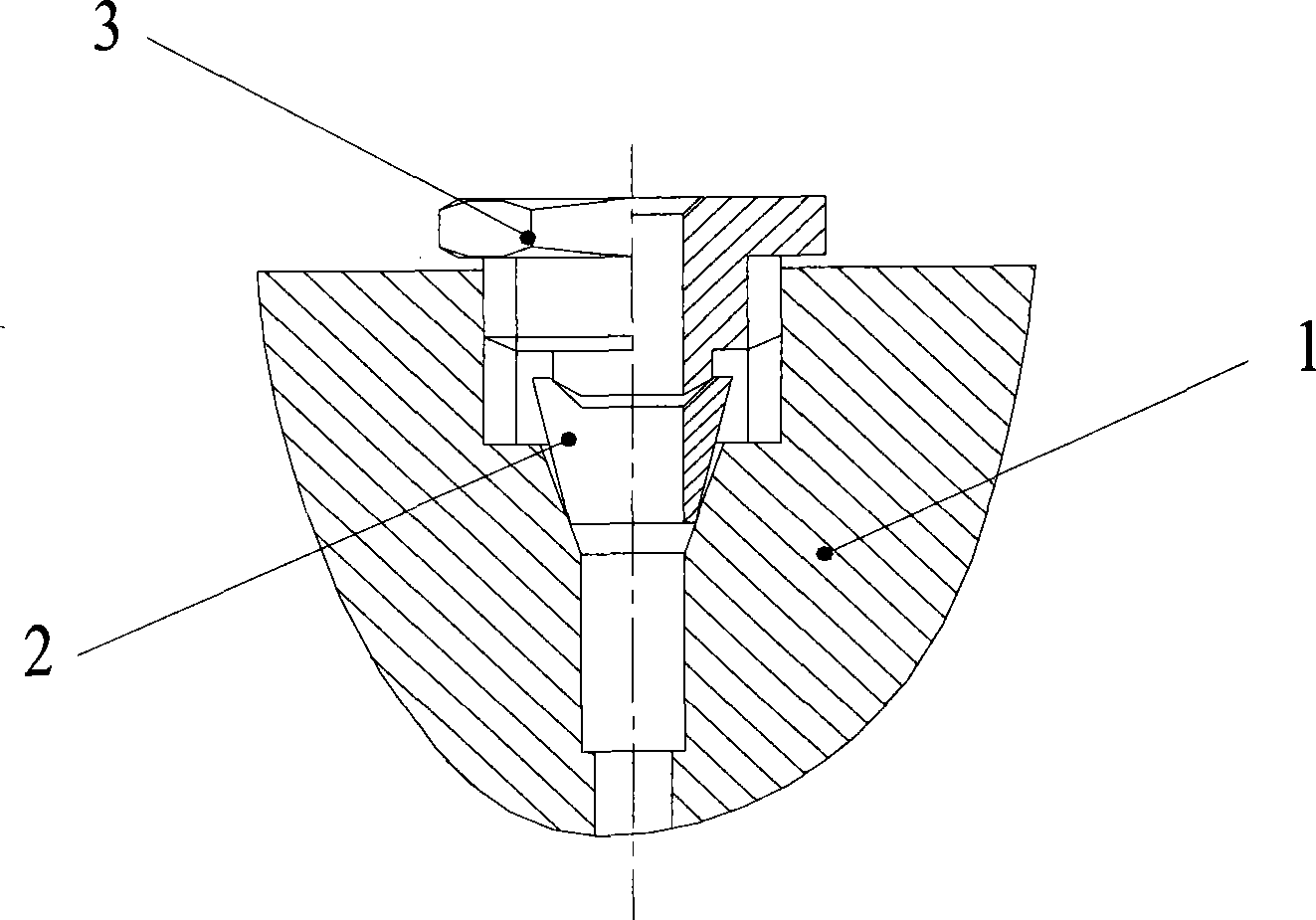

[0009] Such as figure 1 As shown, the embedded ferrule sealing structure is mainly composed of three parts: a joint body 1 with a 24° conical counterbore, a ferrule 2 with a sharp inner edge, and a nut 3 for pressing. Among them, the joint body of the 24° tapered hole is required to be directly processed on the mounting part in the form of a counterbore; the upper end of the nut is a hexagonal force nut, the middle is an external thread connected with the joint body, and the lower end is a ferrule pressing boss. When the nut is tightened, the ferrule is pushed into the 24° tapered hole and deformed accordingly, so that the ferrule and the conical surface of the joint body form a spherical contact seal; at the same time, the inner cutting edge of the ferrule is embedded in the outer wall of the steel pipe to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com