Pipe connection structure

A pipe connection and pipe joint technology, which is applied to cable installation and cable installation in underground pipelines, can solve problems such as poor workability, complicated assembly operations, and cable protection pipe connection obstacles, so as to prevent bad connections and improve operations. Efficiency, the effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

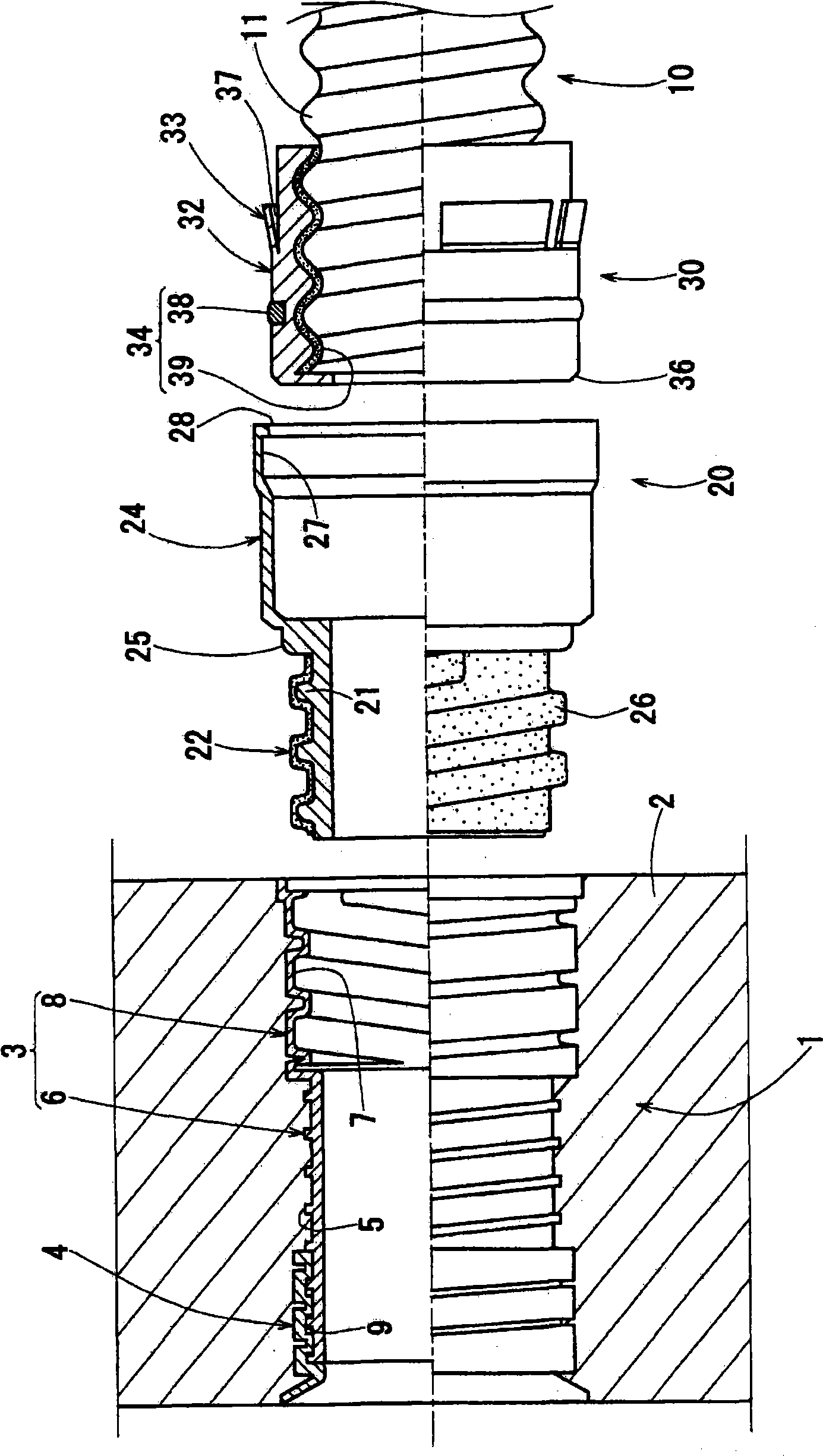

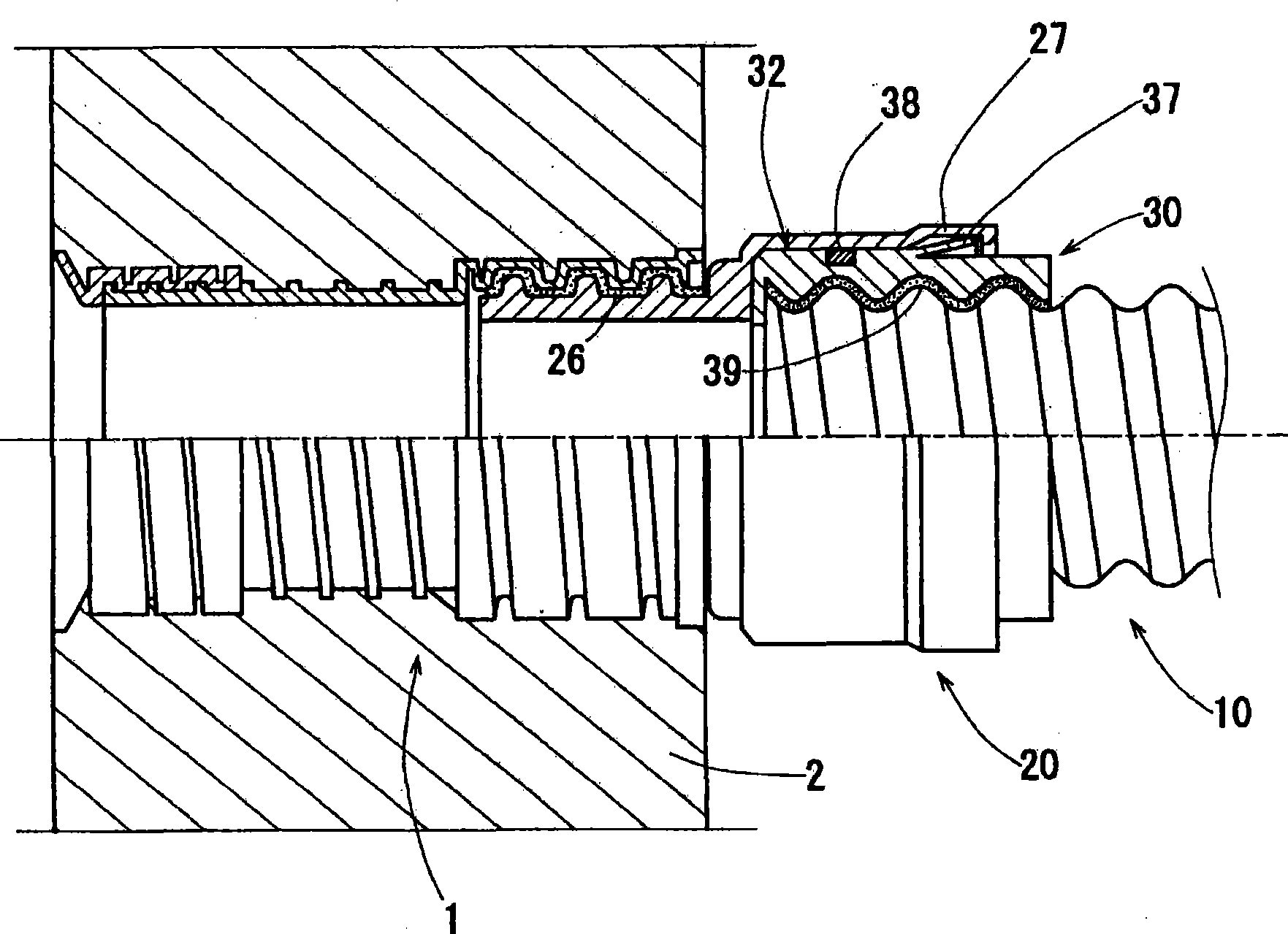

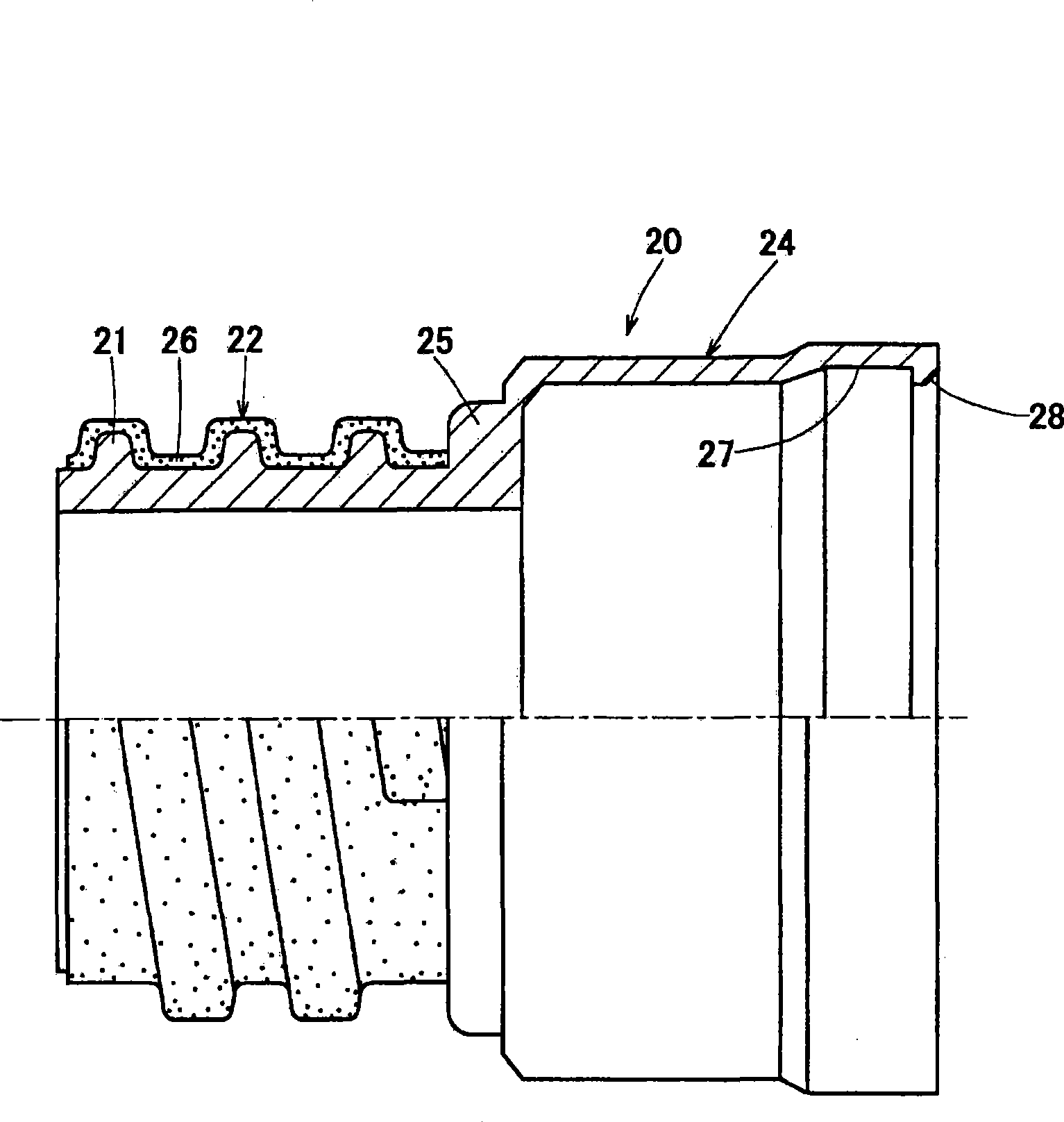

[0028] side reference attached Figure 1 Embodiments of this invention will be described in detail. figure 1 and figure 2 A pipe connection structure according to one embodiment of the present invention is shown. Reference numeral 1 is a pipe mouth member made of, for example, synthetic resin, which is embedded in the wall of the hand hole 2 in a state penetrating in the horizontal direction. The duct opening member 1 is composed of a cylindrical body 3 and a guide port 4 . On the cylindrical main body 3, its one end side is a small-diameter connection cylinder portion 6 forming a helical protrusion 5 on the outer periphery, and the other end side is a large-diameter connection cylinder portion 8 forming a helical groove 7 on the inner periphery. The cylindrical parts 6 and 8 form a continuous structure along the tube axis direction. As for the guide port 4, in order to facilitate the insertion of the cable into the hand hole 2, the diameter of the leading end is enlarged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com