Friction vacuum pump

A technology of vacuum pump and pump stator, applied in the direction of pump, pump element, axial flow pump, etc., to achieve uniform temperature change characteristics and eliminate the effect of assembly work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

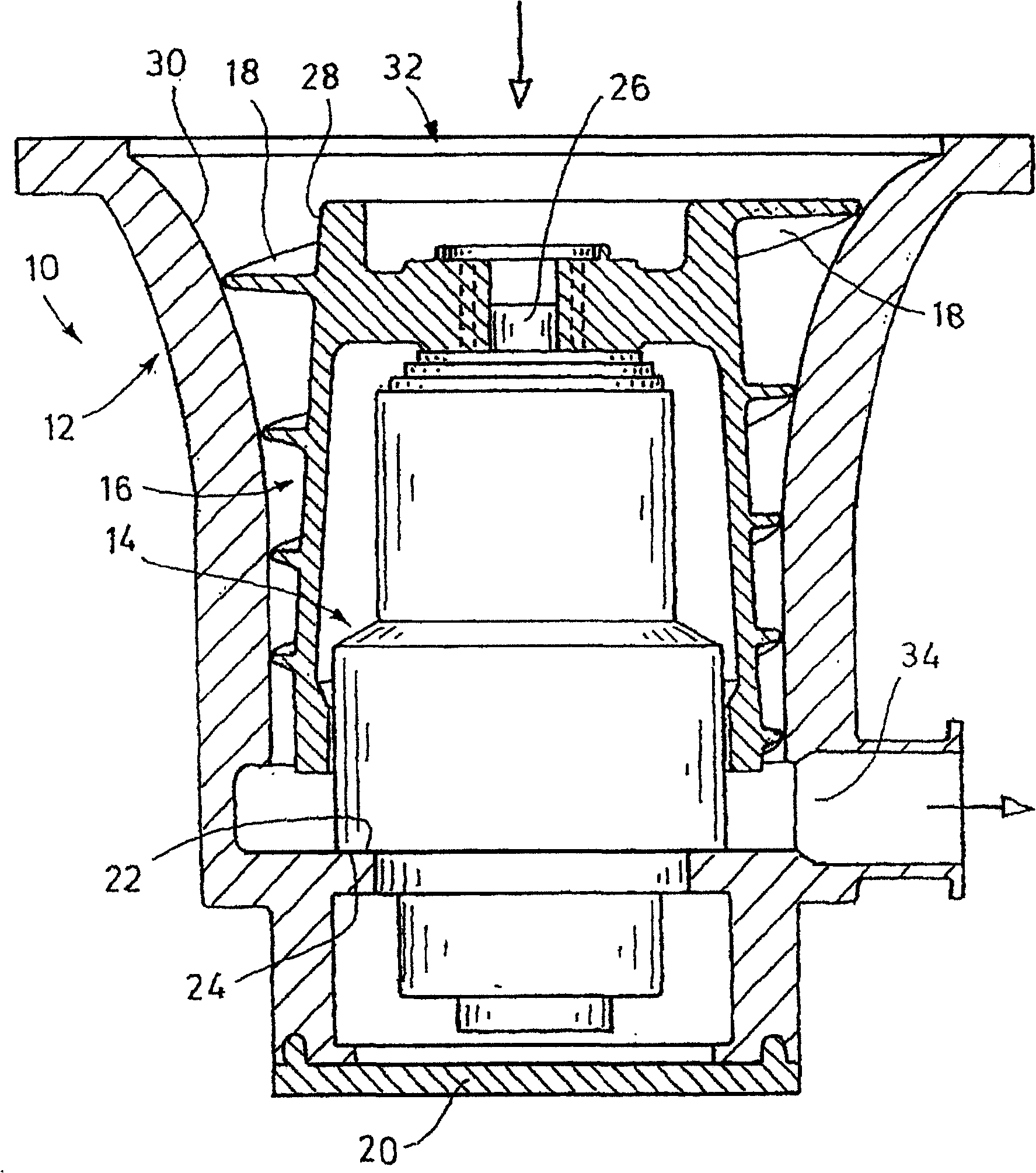

[0017] The drawing shows a friction vacuum pump 10, which is a screw pump, also known as a Holwick pump. The friction vacuum pump 10 basically comprises a housing 12, a cylinder 14 which narrows towards the suction side in a funnel shape, and a pump rotor 16, the cylinder 14 being arranged and fastened in the housing 12 and comprising a not shown rotor holder and The rotor drive, not shown, the pump rotor 16 comprises a plurality of blades 18 arranged helically.

[0018] The housing 12 is of one-piece construction and surrounds the entire axial length of the pump rotor 16 and the barrel 14 including the rotor drive and rotor support. The discharge-side end of the housing 12 is closed by a front-side housing cover 20 .

[0019] In the housing 12 a circumferential shoulder 22 is provided on the inner circumference, on which a corresponding circumferential shoulder 24 of the cartridge 14 is supported gas-tight. The shoulder 22 of the housing 12 and the shoulder 24 of the cartri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com