Oil removing device of cold rolling mill

A technology of cold rolling mill and oil roller, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve the problem of inability to meet the requirements of high-speed strip cold rolling mill for oil removal, affecting the rolling control strip surface quality, easy to The occurrence of sliding belt accidents and other problems, to achieve the effect of convenient and reliable use, reasonable structure design, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with drawings and embodiments.

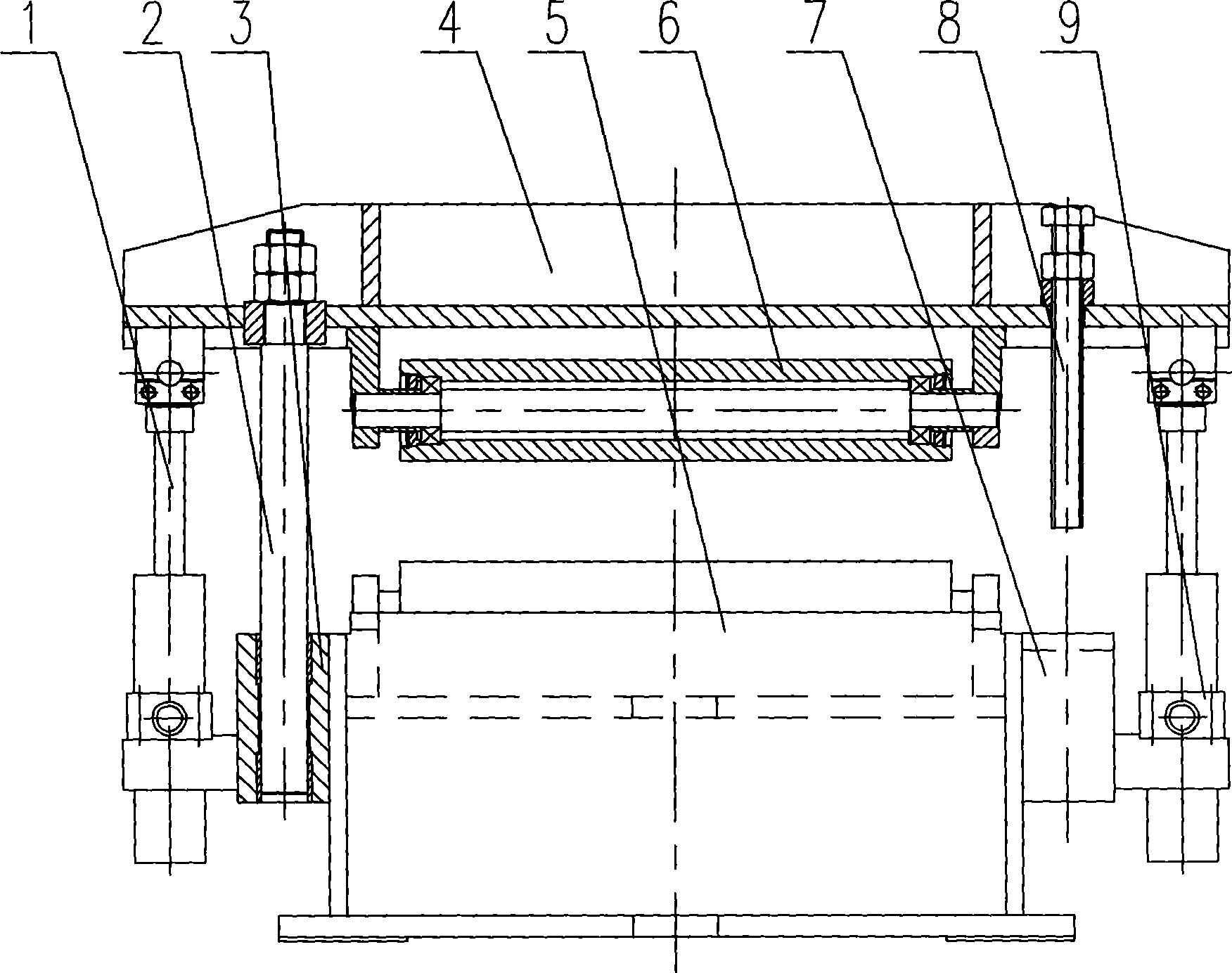

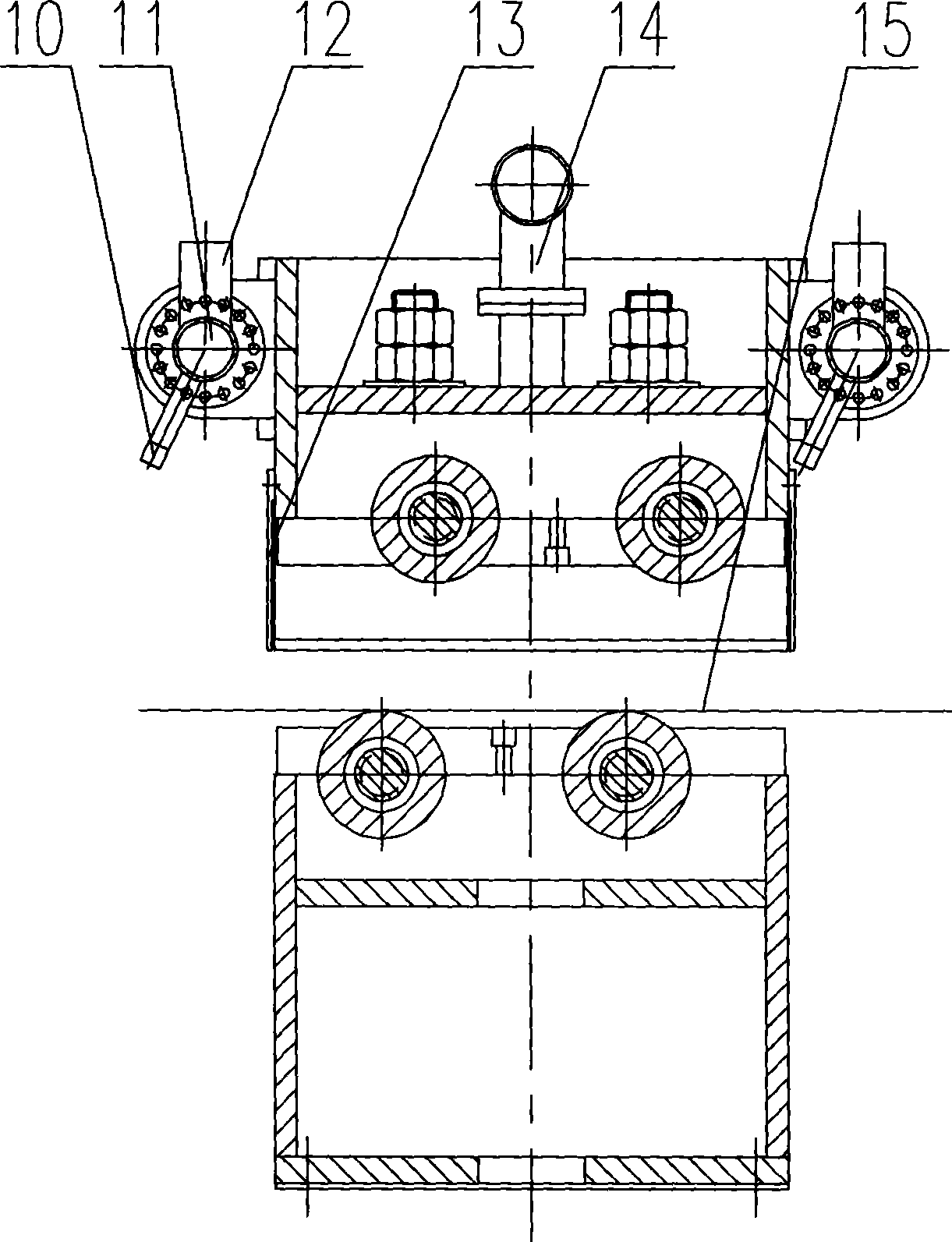

[0010] figure 1 , figure 2 As shown, it includes hydraulic cylinder 1, guide post 2, guide sleeve 3, upper frame 4, base 5, degreasing roller 6, limit block 7, adjusting screw 8, cylinder support 9, nozzle and injection pipe 10, support 11 , Air blowing pipe 12, coaming 13, air extraction pipe 14 and strip 15 etc.

[0011] The present invention includes machine base, degreasing roller, lifting mechanism, roll gap adjustment mechanism, air blowing mechanism, air extraction mechanism, described machine base is made up of base 5 and upper frame 4; Described degreasing roller 6 is 4 pieces altogether, They are respectively placed on the base 5 and the upper frame 4, and are divided into two groups of left and right. Each group of degreasing rollers 6 is arranged in a dislocation up and down, and the horizontal distance between each group of rollers is 50 mm.

[0012] Th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap