Engineering bacteria expressing coenzyme A transferase and beta-keto thiolase and use thereof

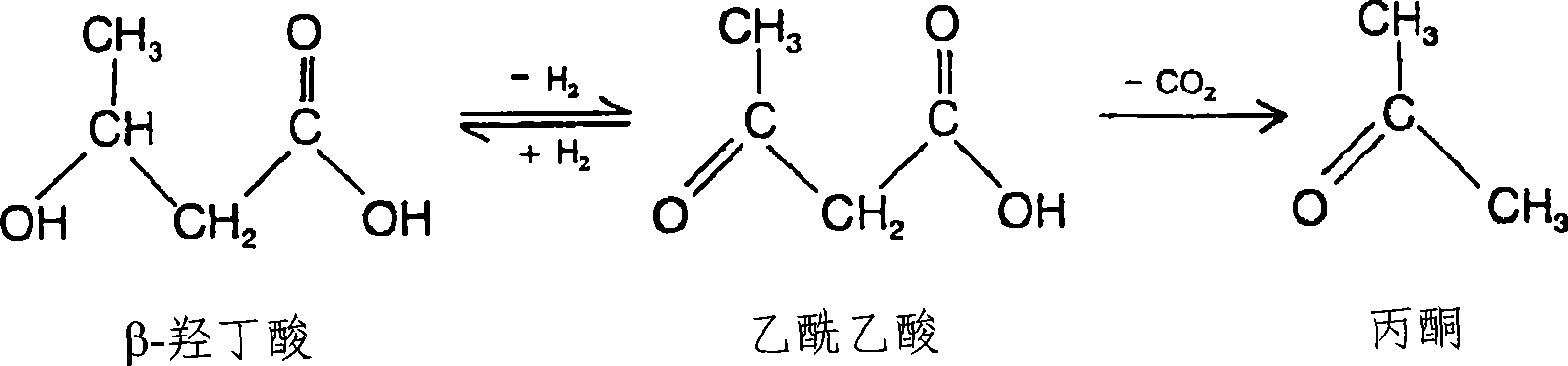

A ketothiolase and engineering bacteria technology, applied in the field of genetic engineering bacteria, can solve the problems of no good production method, unstable acetoacetate, production of acetoacetate, etc., and achieves low cost and high conversion efficiency. , the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

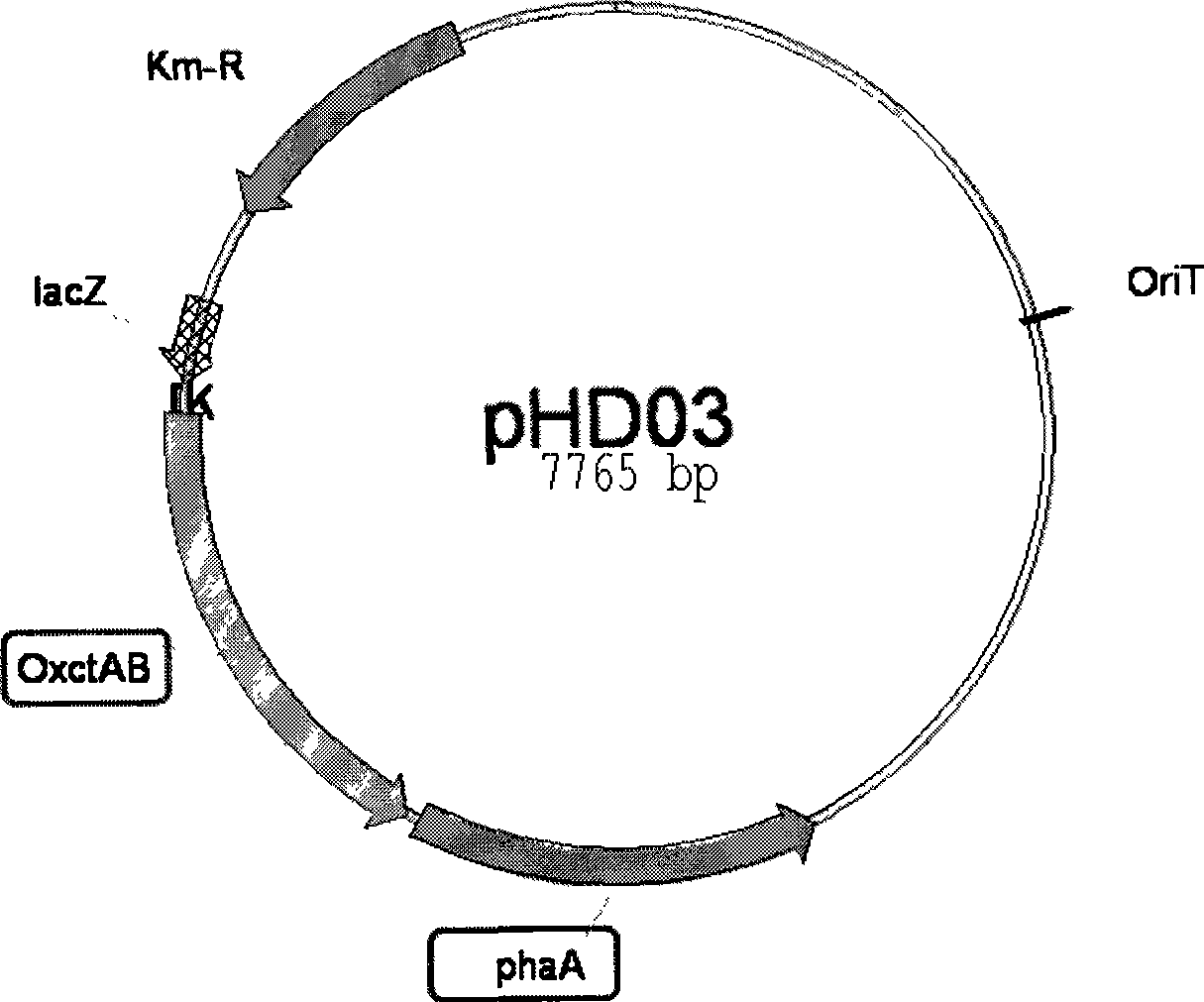

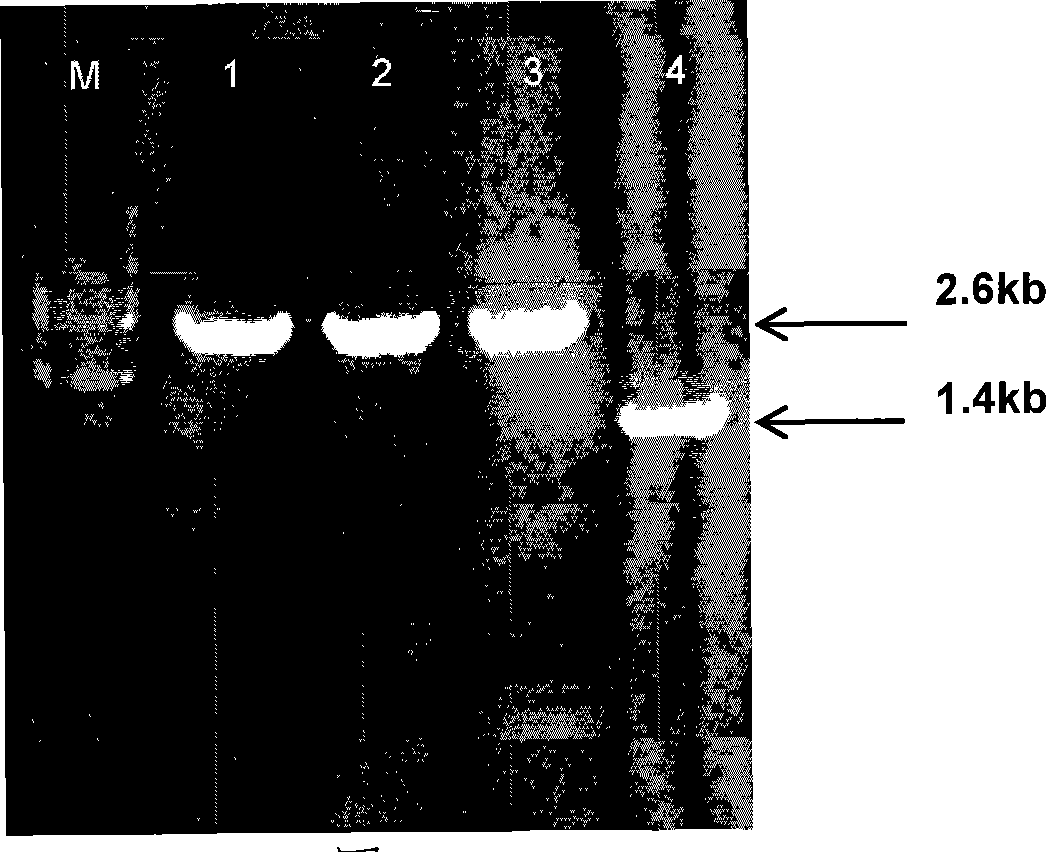

[0040] Example 1, Construction of special-purpose expression engineering bacteria for β-ketothiolase and 3-ketoacid-CoA transferase

[0041] One, the construction of the expression vector containing β-ketothiolase gene (phaA) and 3-ketoacid coenzyme A transferase gene (soctAB)

[0042] 1) Extract the genome (Pohlmann Anne, et al., Genome sequence of the bioplastic-producing "Knallgas"bacterium Ralstonia eutropha H16.Journal Nat Biotechnol.2006,24:1257-1262), using the R.eutropha H16 genome as a template, using pfu enzyme for PCR reaction to amplify the target gene soctAB, and adding SD sequence before the fragment ( Shine-Dalgarno sequence).

[0043] Primers are:

[0044] Sense: 5' AAGCTT GCGAAGC ATG AACAAGGTCTAC 3’

[0045] Hind III SD

[0046] Antisense: 5'G GAGCTC AGCCCGCTTACAGCA 3’

[0047] SacI

[0048] PCR reaction conditions:

[0049] 1.94°C pre-denaturation for 8 minutes;

[0050] 2. Denaturation at 94°C for 30 sec;

[0051] ...

Embodiment 2

[0089] Example 2, Determination of Enzyme Activity of 3-ketoacid-CoA-transferase Expressed by β-Ketothiolase and 3-Ketoacid-CoA-Transferase Special Expression Engineering Bacteria

[0090] Detect the enzymatic activity of the 3-ketoacid-CoA transferase special-purpose expression engineering bacteria constructed in Example 1 and the control strain expressing 3-ketoacid-CoA transferase with the following method, the specific methods are as follows:

[0091] 1) Preparation of bacterial total protein lysate

[0092] a) Centrifuge 100 mL of the desired bacterial solution at 4°C to collect the cells and discard the supernatant.

[0093] b) The cells were washed twice with 50 mM Tris-HCl buffer (pH 8.0), collected by centrifugation, and fully resuspended in 10 mL of 50 mM Tris-HCl buffer (pH 8.0).

[0094] c) Place the suspension container on ice, and perform sonication under low temperature conditions.

[0095] d) 4°C, 10000rpm, centrifuge for 10min. The supernatant is the bacter...

Embodiment 3

[0103] Embodiment 3, shake flask experiment of producing ACAC with Escherichia coli Top10 (pHD03)

[0104] In order to determine the amount of ACAC synthesized in the recombinant bacteria and the concentration difference under various treatment conditions, HS-GC instrument and PID detection method were used to detect the experimental samples.

[0105] Each strain (E.coli Top10 (no), E.coli Top10 (pBBR1MCS2), E.coliTop10 (pHD03)) was cultured with LB medium respectively at 37° C. and 200 rpm overnight; ), were inoculated into 100mL LBGS medium (that is, sodium glucosuccinate medium, containing: 5g / L yeast extract, 10g / L tryptone, 10g / LNaCl, 20g / L glucose and 2g / L sodium succinate, and the rest water, pH 7.0-7.2), 37°C, 200rpm, shake flask culture for 36 hours, add IPTG to a final concentration of 1mmol / L for induction after 8 hours of inoculation, and set up three parallel groups for each strain. Using HS-GC instrument, PID detection method (Lopez-Soriano F J, Argiles J M. Sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com