Sulfur hexafluoride gas sample collection apparatus

A technology for collecting sulfur hexafluoride gas and samples, which is applied in the direction of sampling devices, etc., can solve the problems of cumbersome sampling process, it is difficult to ensure that the sampling container is cleaned and completely isolated, and achieve the effect of ensuring repeatability

Inactive Publication Date: 2009-07-08

STATE GRID CHONGQING ELECTRIC POWER CO ELECTRIC POWER RES INST

View PDF0 Cites 32 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] Since the sampling bag does not have a convenient vacuum valve and pressure display device, it is generally sampled by flushing. First, the air in the sampling bag is removed, and after the sampling bag is connected to the equipment, the sample gas is filled, the valve of the equipment is closed, and the sample gas is discharged. Exclude, so repeat 3 times, and then collect samples, the sampling process is cumbersome, and it is difficult to ensure that the sampling container is cleaned and completely isolated from the outside world

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

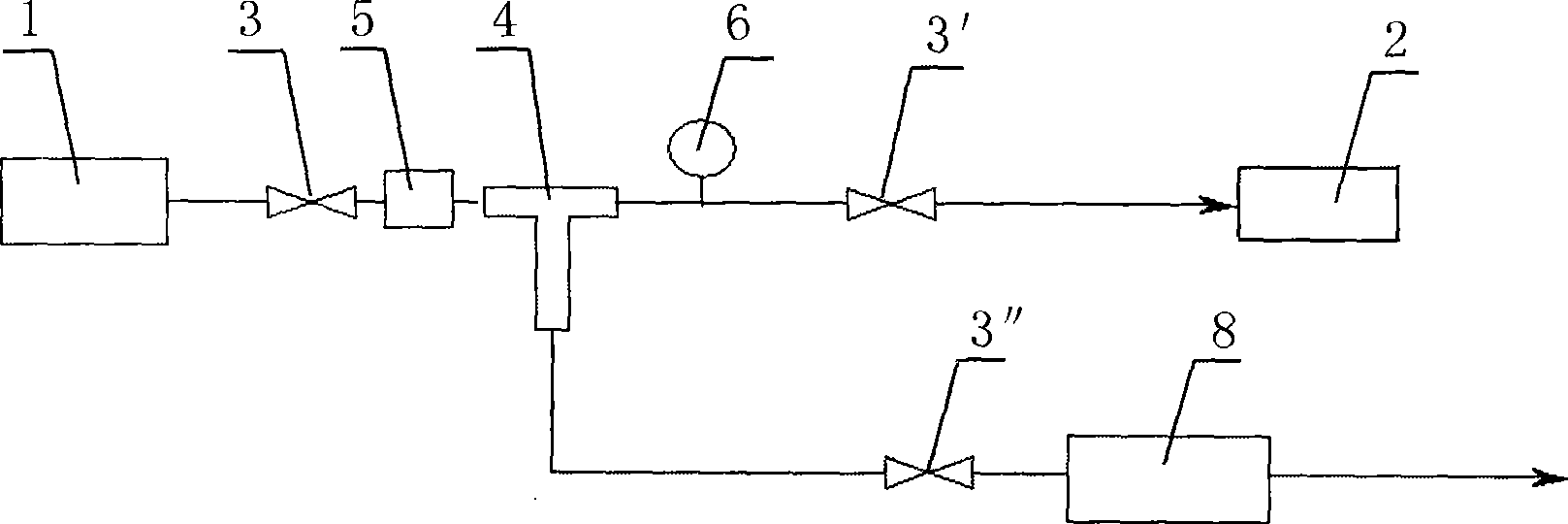

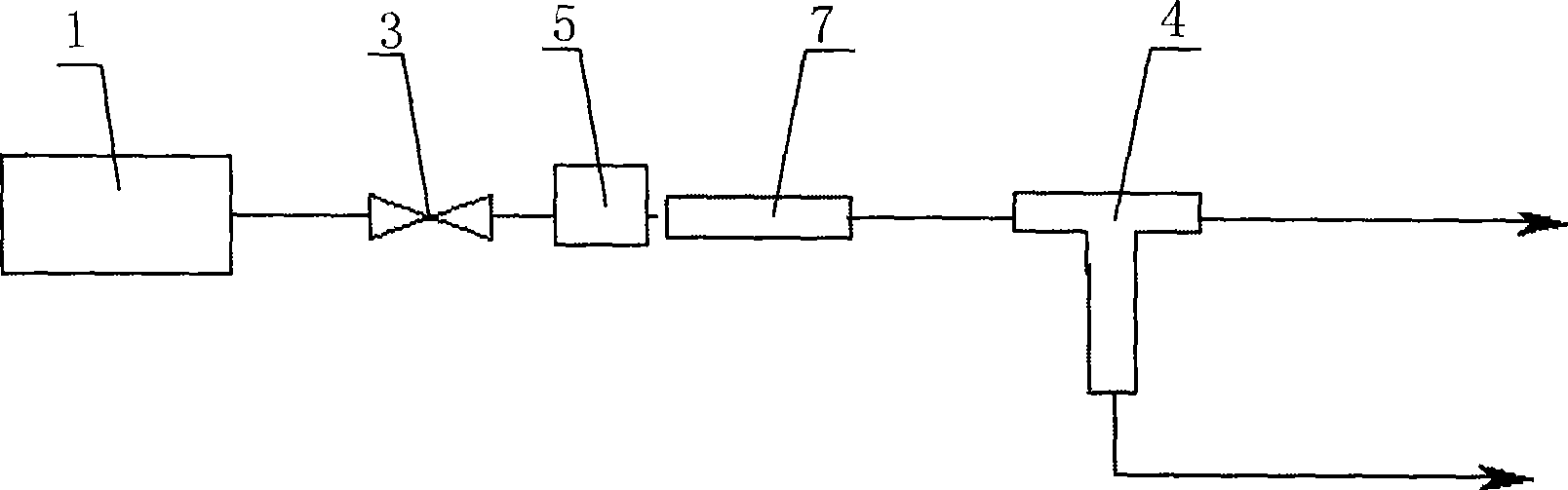

The invention discloses a sulfur hexafluoride gas sample collecting device. The device is provided with a gas picking joint of a fast-inserted pipe, and the appearance of the device is a case body structure provided with an upturning cover; the relative buckling faces of a case body and the upturning cover are provided with a control panel and a display screen respectively; the periphery of the case body is provided with a fast-inserted gas path interface and a power interface; and the case body is provided with a triple valve, an SF6 flow rate electronic controller, a minitype vacuum pump, an electromagnetic valve and an integrated circuit control system inside. The collecting device has the advantages of portable design, full closed sampling, and sample undistortionless, and has the function of controlling the flow rate to precisely set the flow rate so as to be convenient to connect an SF6 gas detector with higher requirements on the flow rate precision. The device completely meets the electric power industry standard of an SF6 gas sampling method for electrical equipment.

Description

technical field [0001] This invention relates to gas sample collection equipment for the power industry, specifically SF 6 (Sulfur hexafluoride) gas sample collection device for electrical equipment. Background technique [0002] With the development of the power industry, SF 6 The number of electrical equipment installed and put into operation continues to increase, and the SF 6 The supervision of gas is becoming more and more important. The samples taken must be able to represent the characteristics of most gases in the equipment body, and must be guaranteed not to be polluted by external gases. [0003] There are two main sampling methods: [0004] 1) Sampling cylinder [0005] When sampling with a sampling cylinder, the cylinder must first be evacuated. Due to the large vacuum pump, this process is generally operated in a laboratory. There is a three-way valve on the top of the sampling cylinder. After the vacuum pump is connected to the sampling cylinder, turn the t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N1/24

Inventor 姚强李毅刘永

Owner STATE GRID CHONGQING ELECTRIC POWER CO ELECTRIC POWER RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com