Automatic control system of Hopkinson press/pull rod

An automatic control system and pull rod technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of low inflation accuracy, increase the workload of operators, waste time, etc., and achieve the effect of improving inflation accuracy

Inactive Publication Date: 2010-11-10

INST OF MECHANICS - CHINESE ACAD OF SCI

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The existing Hopkinson pressure and pull rod inflators must inflate each air chamber separately, which increases the workload of the operator, and the speed control of the bullet must be roughly estimated manually to determine each air chamber pressure, and then manually control the inflator to inflate the gas chamber, which wastes a lot of time and the inflation accuracy is not high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

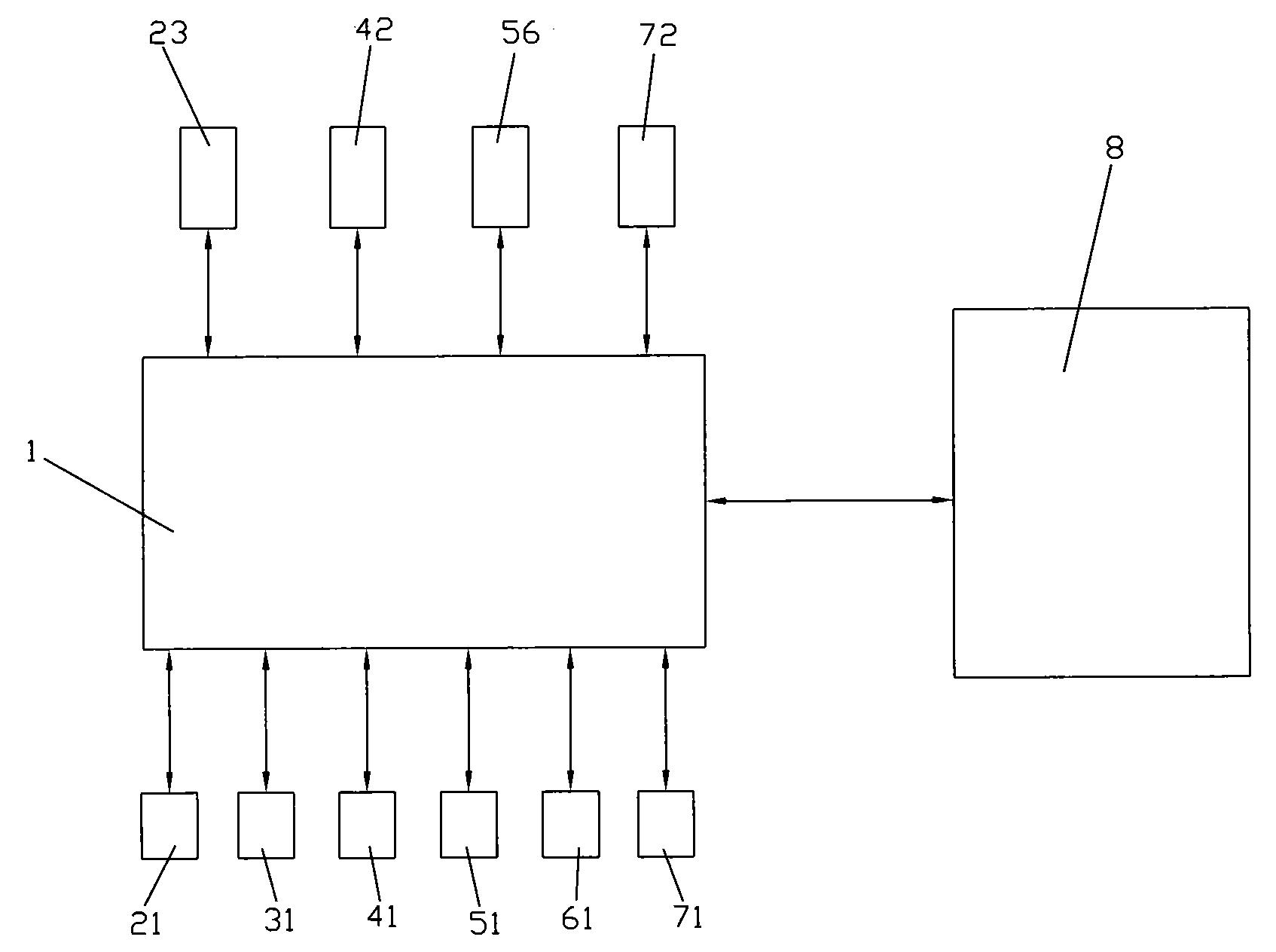

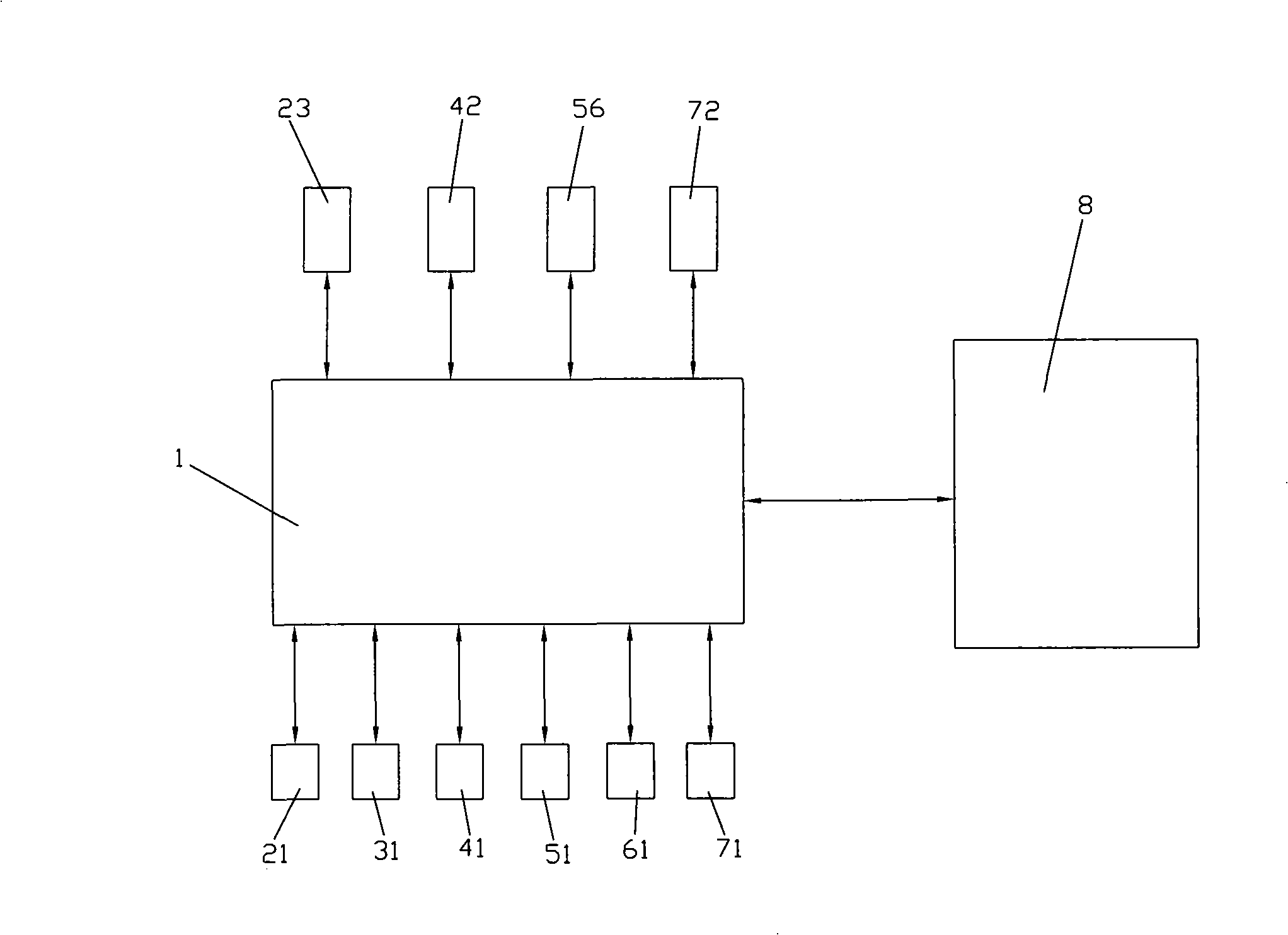

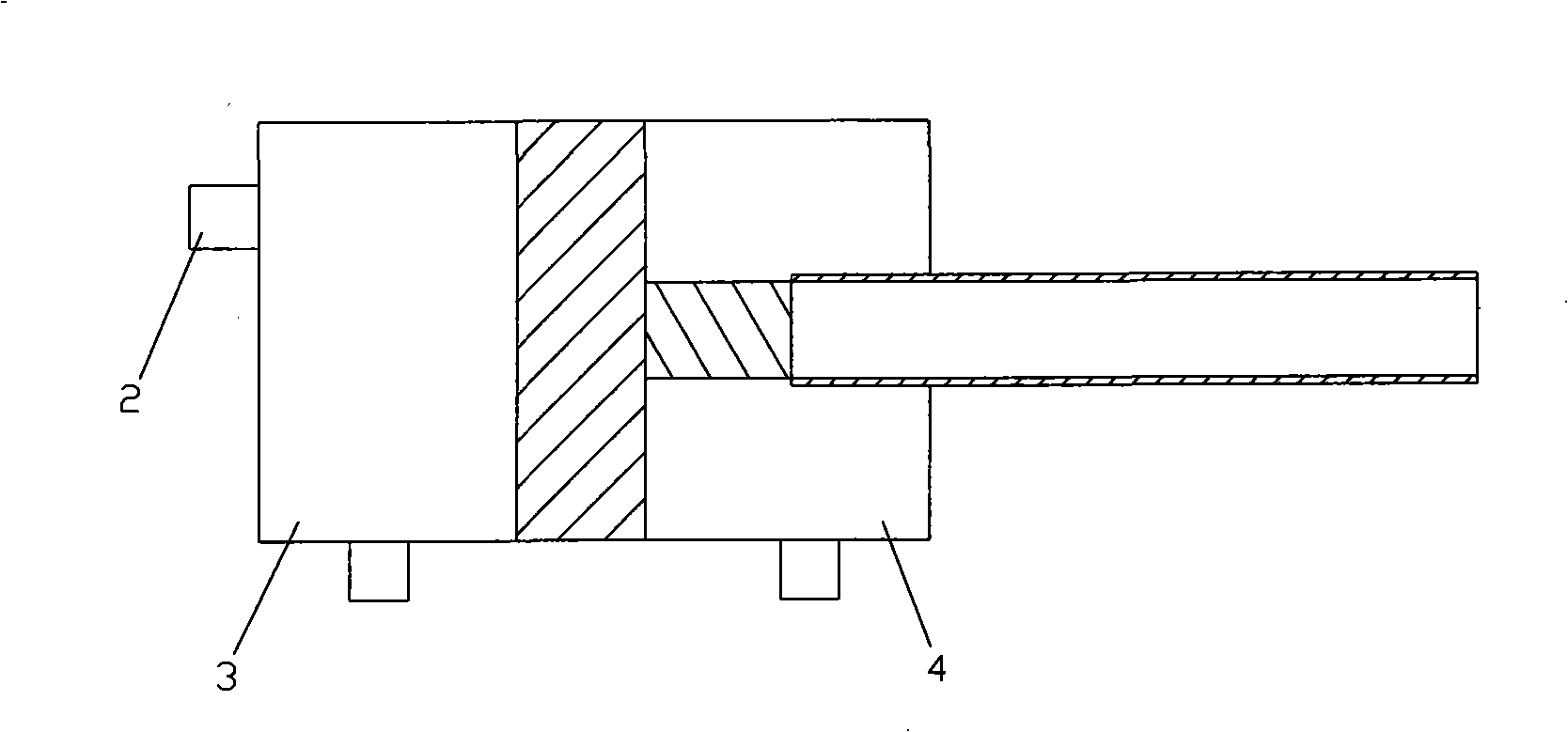

The invention discloses an automatic control system for Hopkinson pressure (pull) rod, which comprises a Hopkinson pressure (pull) rod body and an air inflation control device. The air inflation control device comprises a PLC programmable controller, a pressure sensor, an instruction input device and an electromagnetic valve, wherein the pressure sensor is used for monitoring pressure in each airchamber of the Hopkinson pressure (pull) rod body in real time; and the PLC programmable controller receives instruction signals of the instruction input device to control on and off of the electromagnetic valve, and inflates the each air chamber of the Hopkinson pressure (pull) rod body according to a logical order. The automatic control system for the Hopkinson pressure (pull) rod can carry outHopkinson pressure (pull) experiments at the same time, saves time, and improves experiment accuracy.

Description

Hopkinson pressure and tension rod automatic control system technical field The invention belongs to the research field of high-temperature dynamic mechanical properties of materials, in particular to an automatic control system for Hopkinson pressure and tension rods. Background technique The Hopkinson pressure and rod device is one of the most common equipment used to measure the dynamic properties of materials. At present, there are generally two propulsion methods for the Hopkinson pressure and rod device: gunpowder type and high-pressure gas type. Because the gunpowder propulsion method is dangerous and its operation is relatively cumbersome, it is not suitable for experimental research. The Hopkinson pressure using high-pressure gas propulsion, the tension gun and compression gun on the pull rod have multiple air chambers, and the inflation of each air chamber has different logical relationships. During the experiment, it is necessary to adjust the Hopkinson The flo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N3/02

Inventor 魏延鹏段祝平

Owner INST OF MECHANICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com