Electric power cord accommodation structure for electric appliance

A technology of electrical equipment and storage structure, applied in the field of power cord storage structure, can solve problems such as damage to the insulation layer of the power cord, and achieve the effects of avoiding shrinkage marks, avoiding damage, and good connection firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

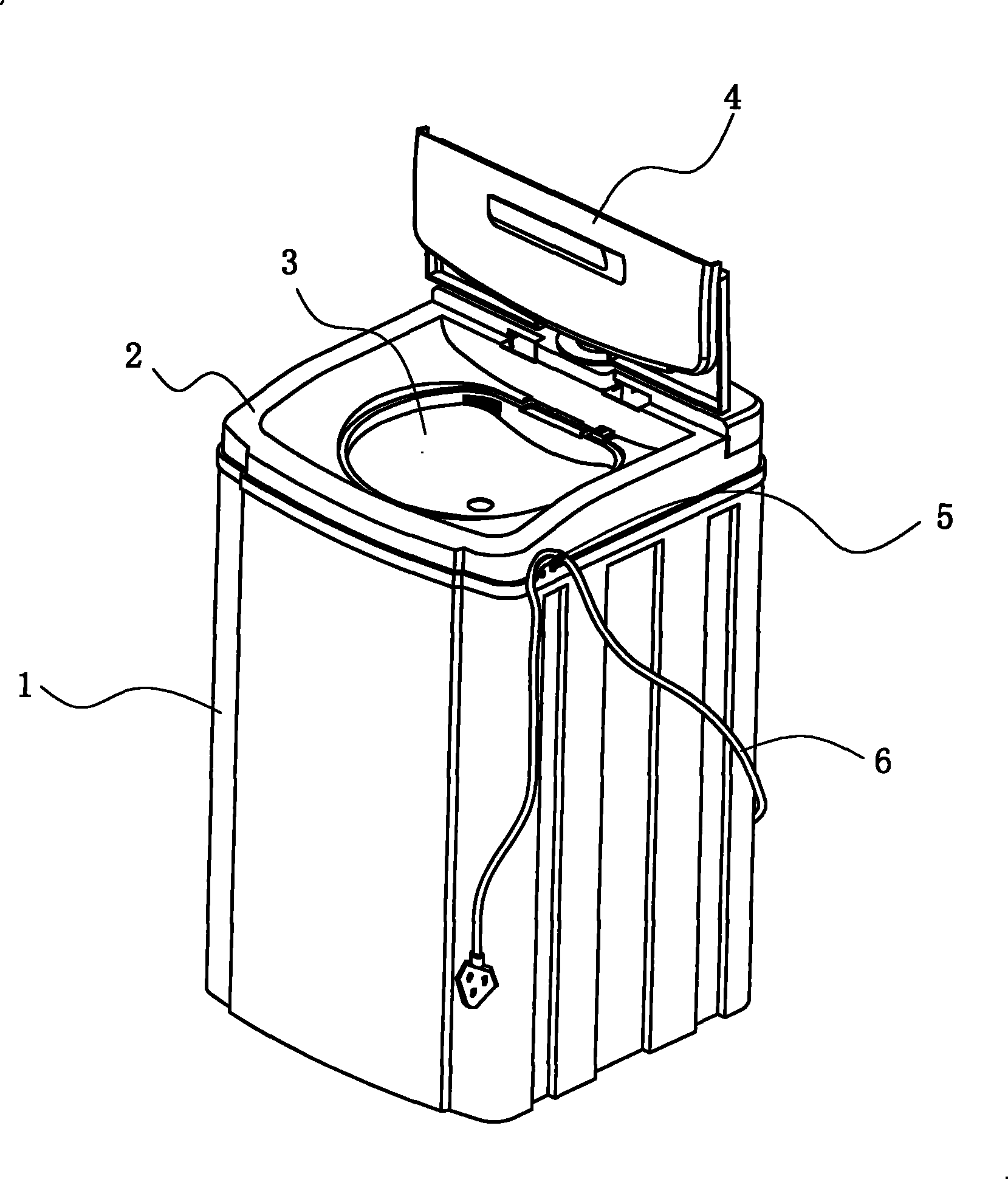

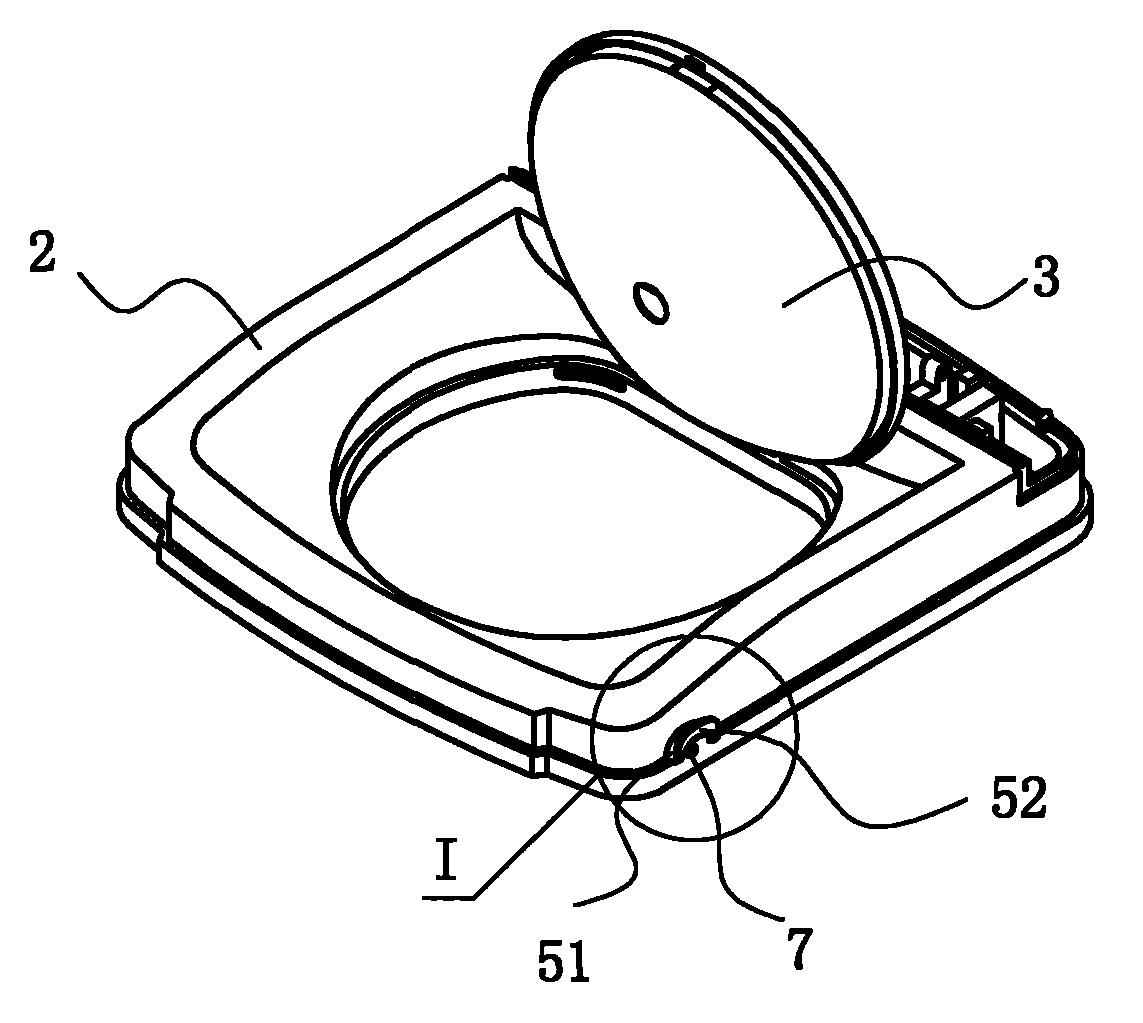

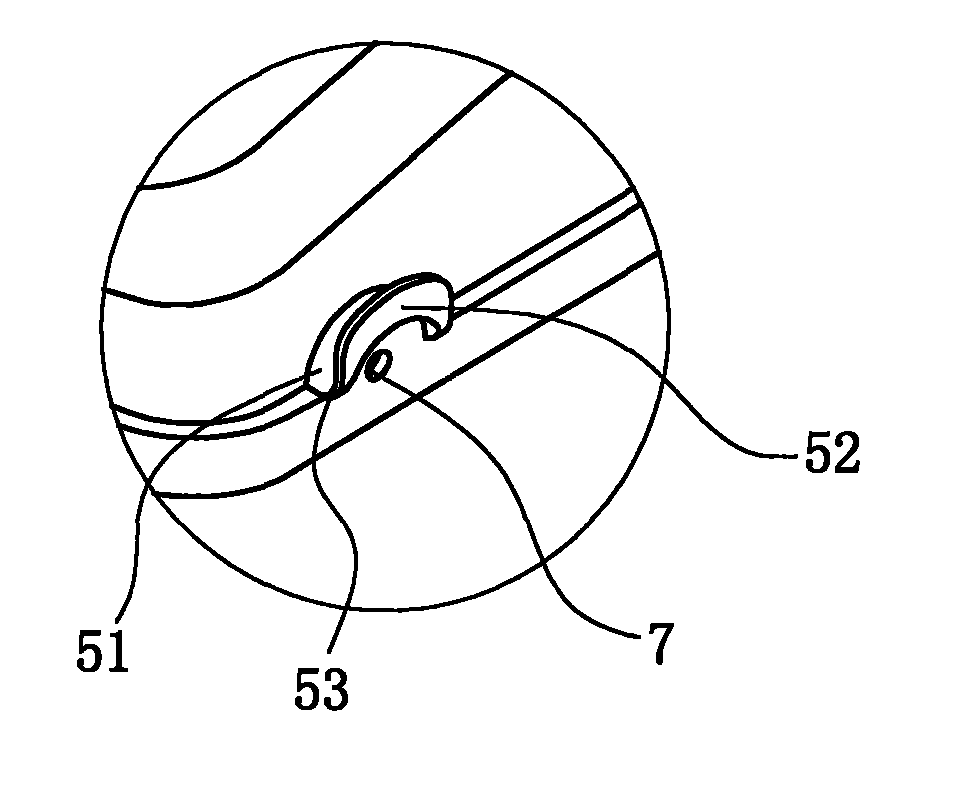

[0017] Such as figure 1 Shown is the outline drawing of the dehydrator, which includes an organism, an inner cover 3 and an outer cover 4, wherein the body includes an organic casing 1 and a frame 2 fixed above the casing by screws 7, the inner cover 3, The outer cover plates 4 are respectively hinged on the surrounding frame 2 . The power cord 6 that provides power for the dehydrator is led out from the rear side of the casing 1. The power cord storage structure is a hook 5 that is arranged on the side of the frame and has an L-shaped cross section. The hook 5 is connected to the bottom of the frame. The side is a connecting piece 51, and the upper surface of the connecting piece is designed as an outwardly convex arc-shaped piece structure, and the vertical side of the hook is a limiting piece 52. In this embodiment, the above-mentioned h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com