Magnetic energy boosting machine

A booster and magnetic energy technology, applied in the direction of generators/motors, electrical components, etc., can solve problems such as unreasonable configuration of engines, and achieve the effects of reducing energy consumption, saving energy, and reducing configuration power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

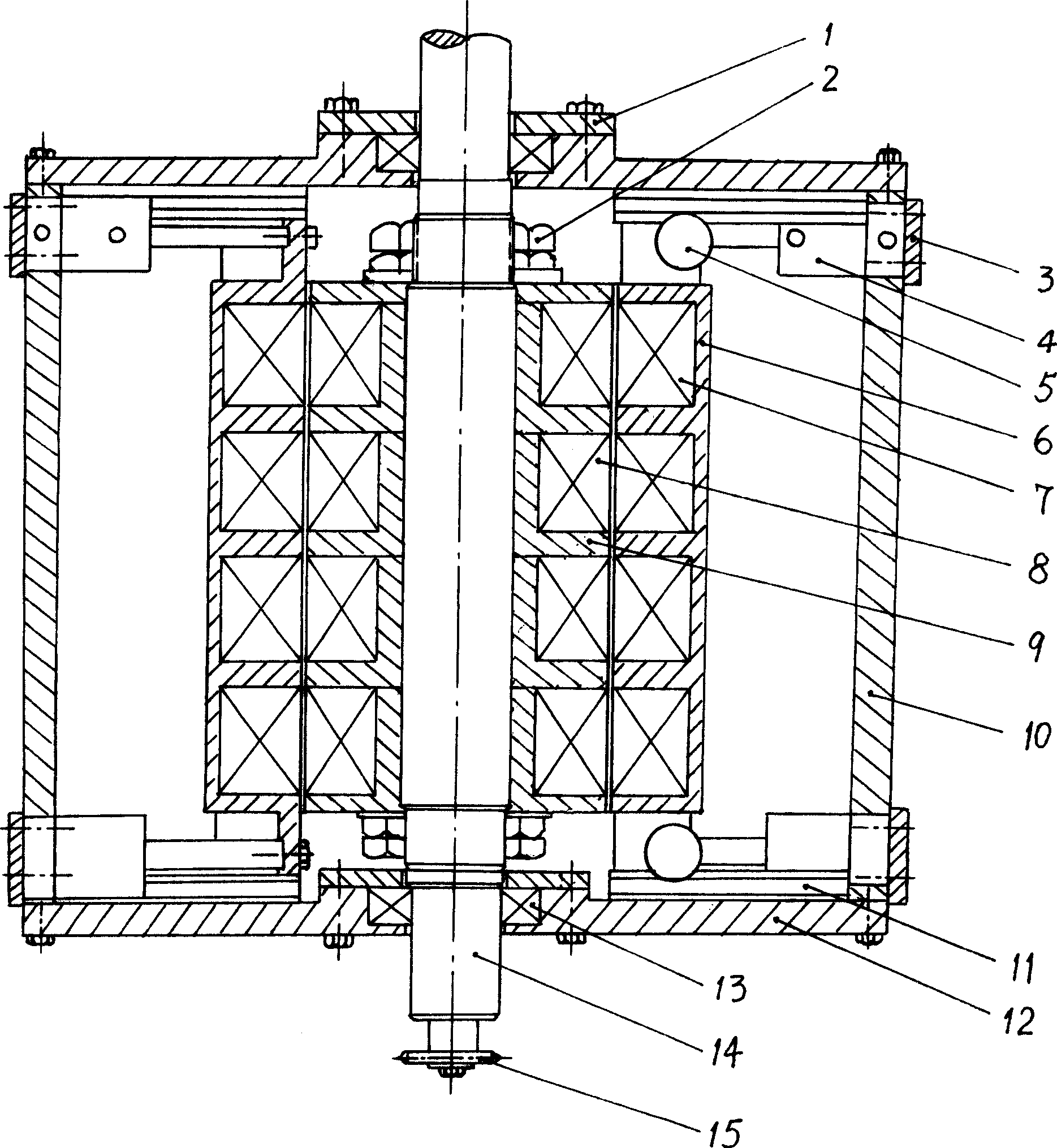

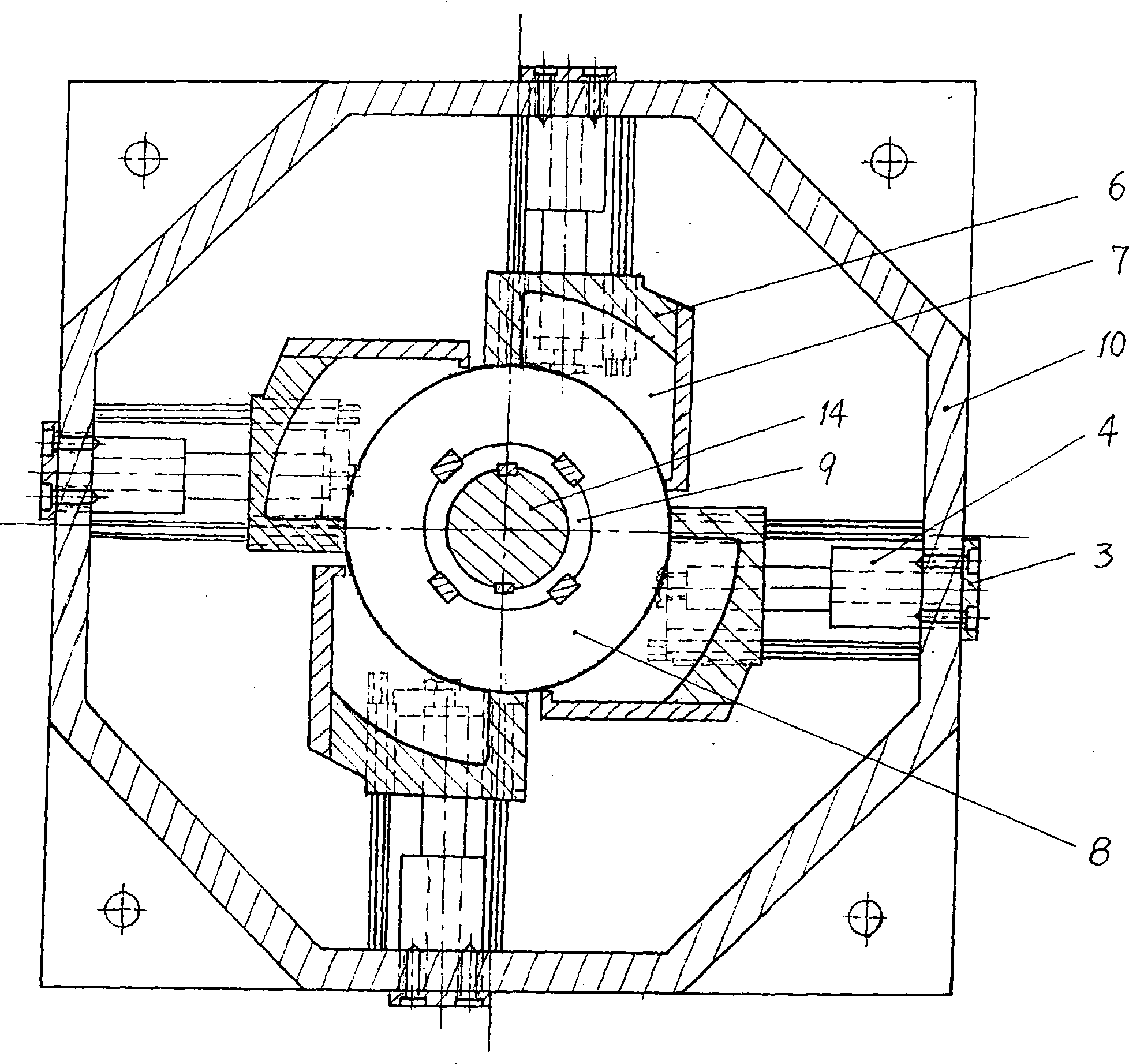

[0013] Such as figure 1 As shown, the box body 10 is a regular octagonal cylindrical shell, and the upper and lower ports of the box body 10 are respectively connected with end caps 12 . The main shaft 14 is supported by bearings 13 in the central holes of the upper and lower end covers. A bearing cover 1 is sealed on the bearing port. The lower end of the main shaft 14 is connected with a transmission mechanism 15 that drives the main shaft to rotate; in the middle of the main shaft 14, there is a four-layer magnetic ring seat 9 made of a magnetic isolation material, and four magnetic rings spaced apart from each other are housed in the magnetic ring seat 9. Ring 8; upper and lower nuts 2 are screwed on the main shaft 14 to fix the magnetic ring seat 9 in the middle.

[0014] The magnetic push mechanism includes parts such as cylinder 4, magnetic block seat 6 and magnetic block 7. Every cover magnetic push mechanism can have one to two cylinders 4. figure 1 There are uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com