Power supplying device for mechanical equipment and method for reducing configuration power of mechanical equipment

A technology for mechanical equipment and power reserve, applied in sequence/logic controller program control, electrical program control and other directions, can solve the problems of mechanical equipment configuration power damage, no early warning of mechanical equipment failure or damage, power waste and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

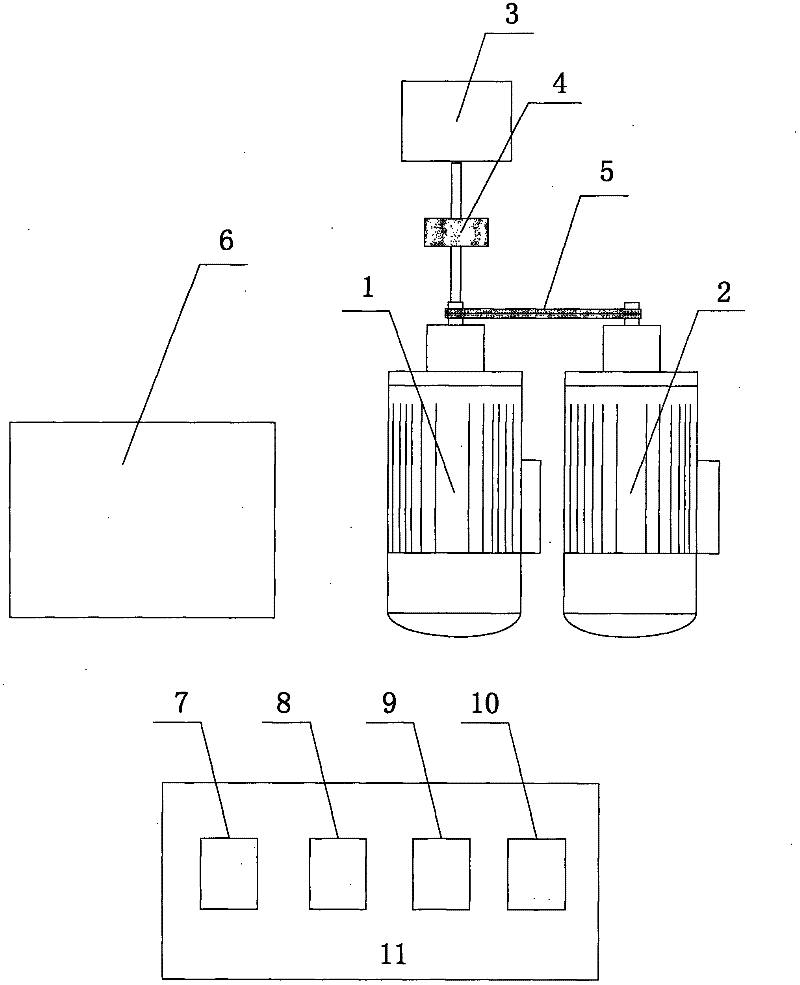

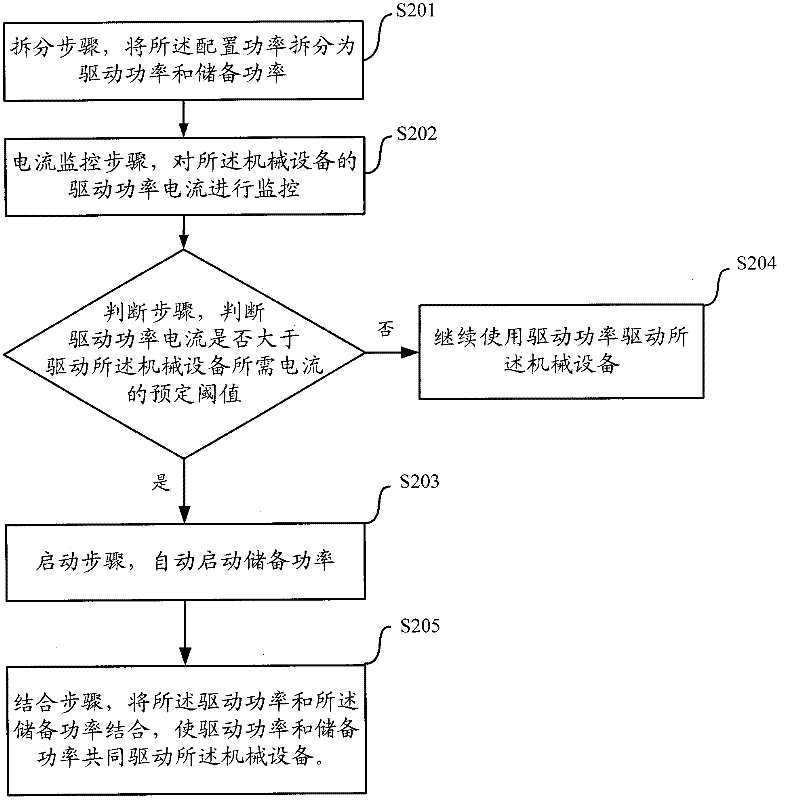

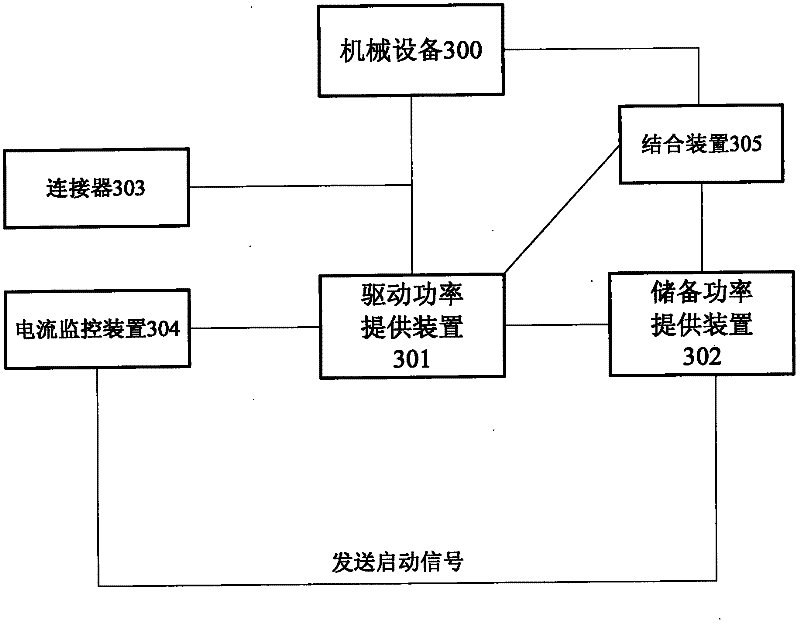

[0031] The following will refer to the attached Figure 1-3 The present invention is further described in detail.

[0032] figure 1 It is a schematic diagram of the hardware connection structure of a power supply device of a mechanical device according to a preferred embodiment of the present invention. Such as figure 1 As shown, the reference numerals in the figure represent respectively as follows:

[0033] 1. Drive power supply device 2. Reserve power supply device

[0034] 3. Mechanical equipment 4. Connectors

[0035] 5. Combined device 6. Control box

[0036] 7. Driving power ammeter 8. Current monitoring device

[0037] 9. Alarm device 10. Reserve power ammeter

[0038] 11. Electrical instrument box

[0039] Wherein, the driving power supply device 1 is used to provide the mechanical equipment 3 with the driving power required to drive the mechanical equipment 3, the driving power here is different from the traditional driving power, and the setting of the tradi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com