Servo motor control-based multi-pump combination controlled hydraulic power system

A technology of hydraulic power system and servo motor, which is applied in the safety of fluid pressure actuation system, fluid pressure actuation system components, servo motor components, etc., can solve the problem of shortening the service life of oil pumps and controllers, large volume of compressed hydraulic oil, Overload capacity impact and other issues, to achieve the effect of improving product competitiveness, reducing procurement costs, and reducing pressure-holding energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

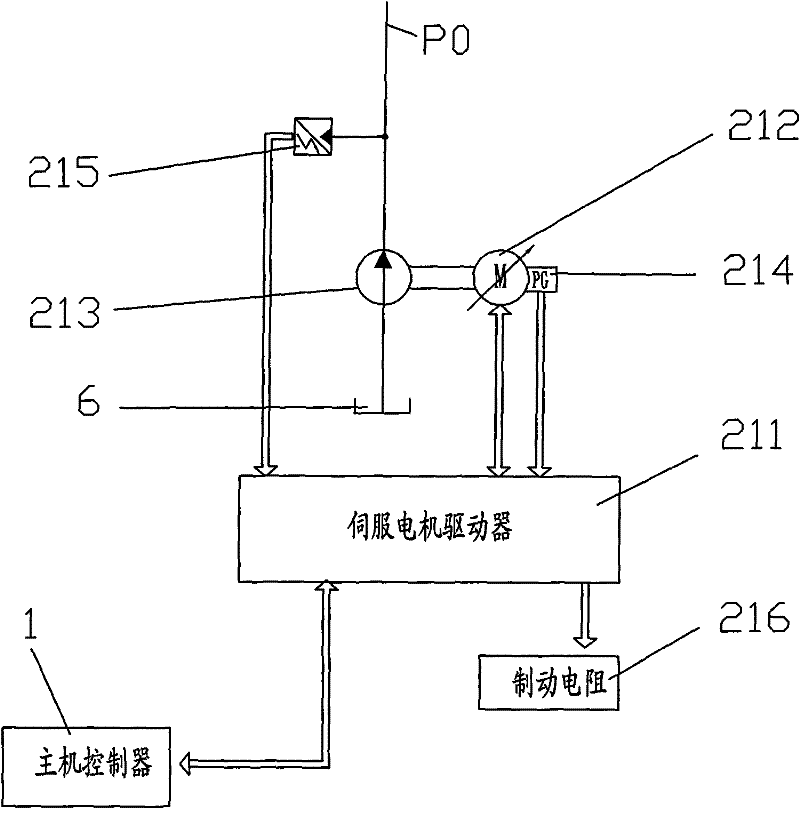

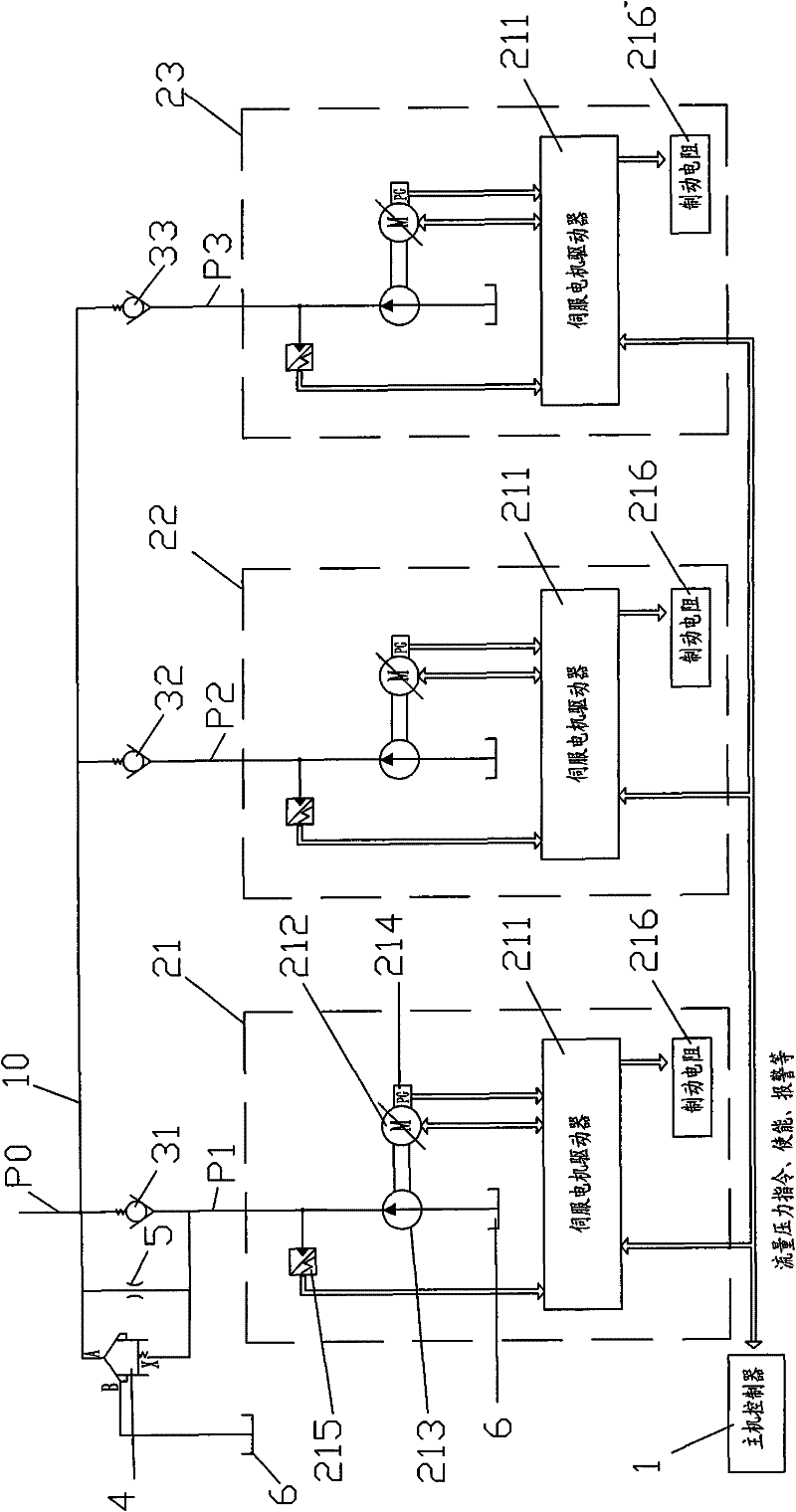

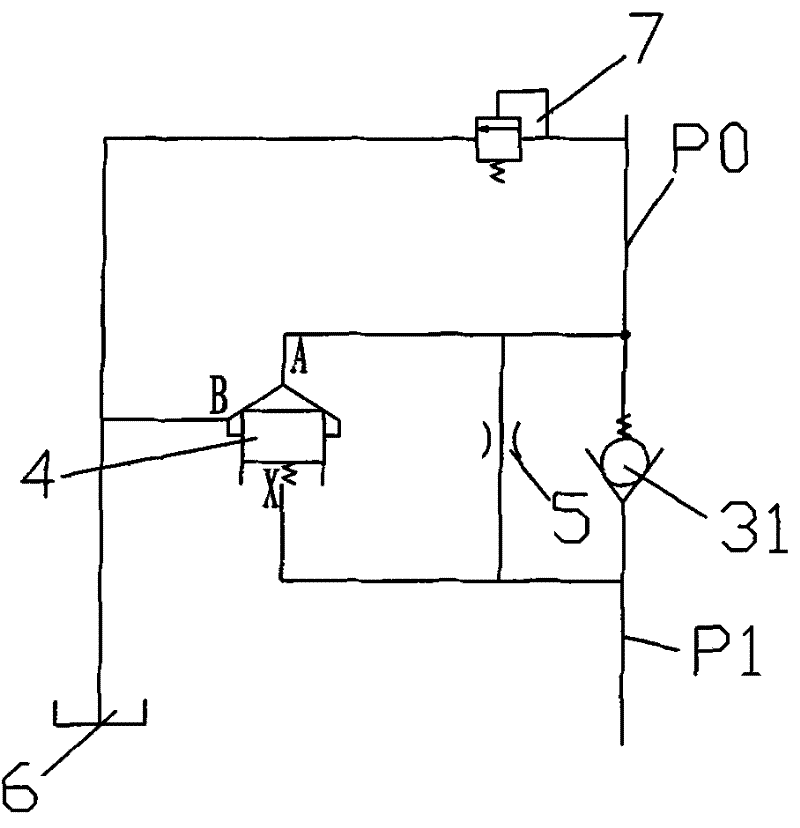

[0028] The present invention is a multi-pump combination control hydraulic power system based on servo motor control, such as figure 2 As shown, it includes a host controller 1, at least 2 servo pumps (3 servo pumps in this embodiment), an oil pipe 10, and an oil tank 6. Pipe P0, in all servo pumps (eg image 3 As shown), there is one main servo pump 21, the oil pipeline where the main servo pump 21 is located constitutes the main control branch oil pipeline P1 of the system, and the branch oil pipelines P1, P2 and P3 where all the servo pumps are located are entering the main oil pipeline of the system A check valve 31, 32, 33 is respectively connected in series before P0, and a main pressure controller is connected in parallel at both ends of the check valve 31 on the main servo pump 21, and the main pressure controller includes a cartridge valve 4 and The differential pressure orifice 5, the oil inlet chamber A and the control chamber X of the cartridge valve 4, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com