Filter element for surface condensate liquid filter

A surface condensation and filter technology, applied in the field of filters, can solve the problems of improper handling, unfavorable protection of the environment, and sharing of insufficient materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

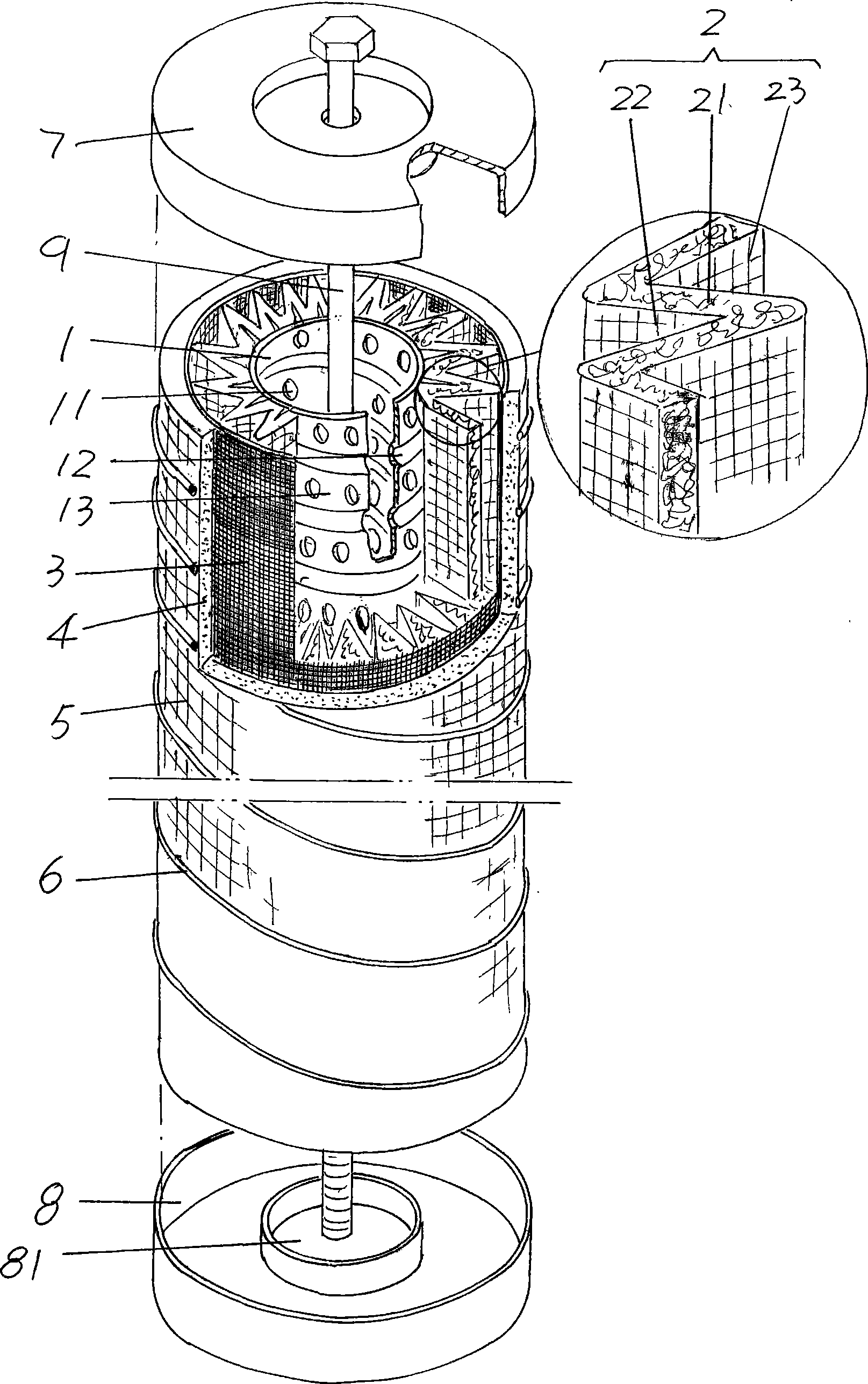

[0017] please see figure 1 , the filter element skeleton cover 1 whose material is preferably made of metal is given. Taking the position shown in the current figure as an example, the height direction of the filter element skeleton cover 1 is provided with medium outlet holes 11 distributed at intervals throughout the whole body. The filter element skeleton cover 1 is also formed with grooves 12 in an interval distribution state, and the convex surface 13 is formed between adjacent grooves 12, and the spaced structure between the grooves 12 and the convex surface 13 helps to strengthen the filter element skeleton cover 1. strength. The preferred shape of the groove 12 is U-shaped, and the aforementioned medium outlet hole 11 is set on the convex surface 13 . if will figure 1 The position changes from the current state to the lying state, that is, deflects to the left or right by 90°, then, the height direction of the filter element skeleton sleeve 1 defined by the applicant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com