A waste heat utilization type methanol evaporator

A methanol evaporator, waste heat technology, applied in evaporation devices, chemical instruments and methods, sustainable manufacturing/processing, etc., can solve the problem of inability to generate high flow rate and large flow of evaporation steam, low energy utilization, poor boiling heat transfer, etc. problems, to achieve the effect of increasing the steam generation rate, stabilizing the amount of steam, and increasing the heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

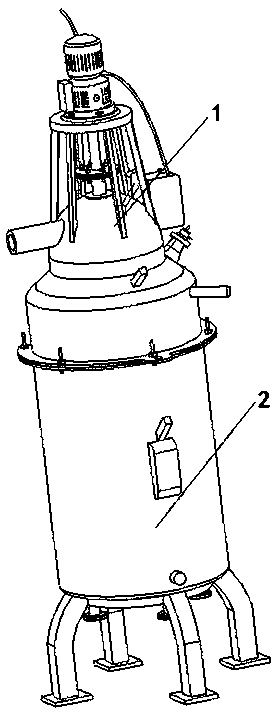

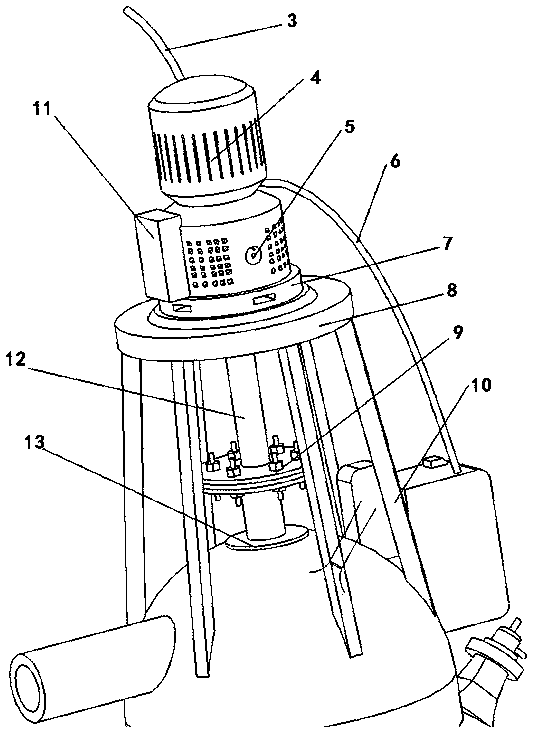

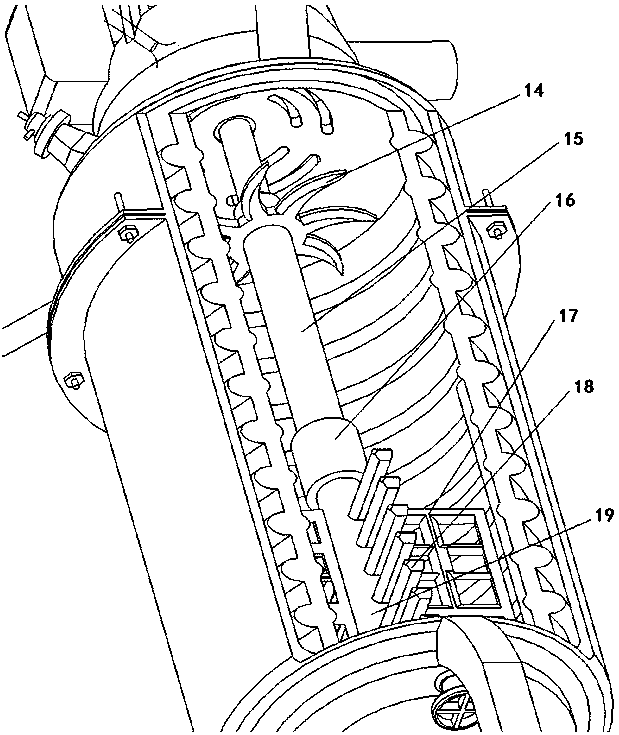

[0048] Such as Figures 1 to 8 as well as Figure 10 As shown, the waste heat utilization methanol evaporator includes a three-layer reaction chamber system 1, a mechanical transmission stirring system 2 and a control device, and the three-layer reaction chamber system 1 is inserted with a mechanical transmission stirring system 2;

[0049]The three-layer reaction chamber system 1 includes a corrosion-resistant magnetic steel plate 20, zeolite particles 21, a refractory inner cavity 22, a fluid outlet 23, an electric heating rod 24, a threaded coil 25, a high-strength ceramic shell 26, and a high-strength titanium alloy inner cavity. Cavity 27, high-strength ceramic base plate 28, fluid inlet 29, emergency pressure relief valve 30, methanol injection hole 31, steam regulating chamber 32, grid base plate 33, small sprinkler 34, water tank 35, atomizing nozzle 36, measurement module Ⅰ37, measurement module Ⅱ39, observation panel 40, steam outlet 41, titanium alloy knob 45 and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com