Connection structure for actuator and fuel injection pump of diesel engine

A connection structure and actuator technology, which is applied in the direction of fuel injection pumps, machines/engines, mechanical equipment, etc., can solve problems such as complex assembly process, reduced system adjustment accuracy, out-of-synchronization of actuators and fuel injection pump racks, etc., to overcome stuck effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

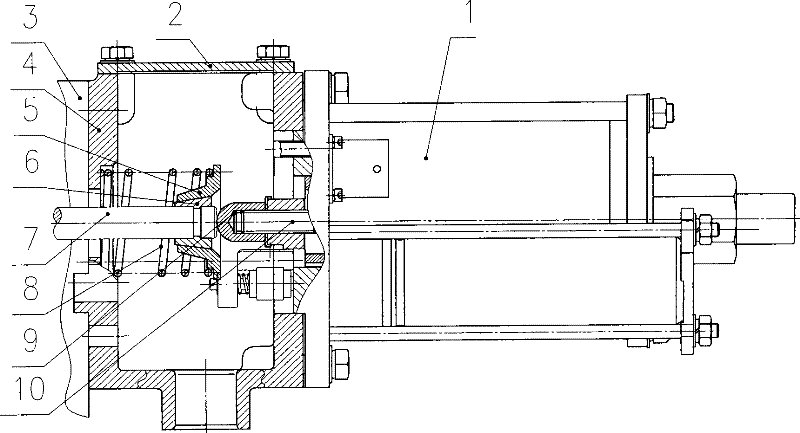

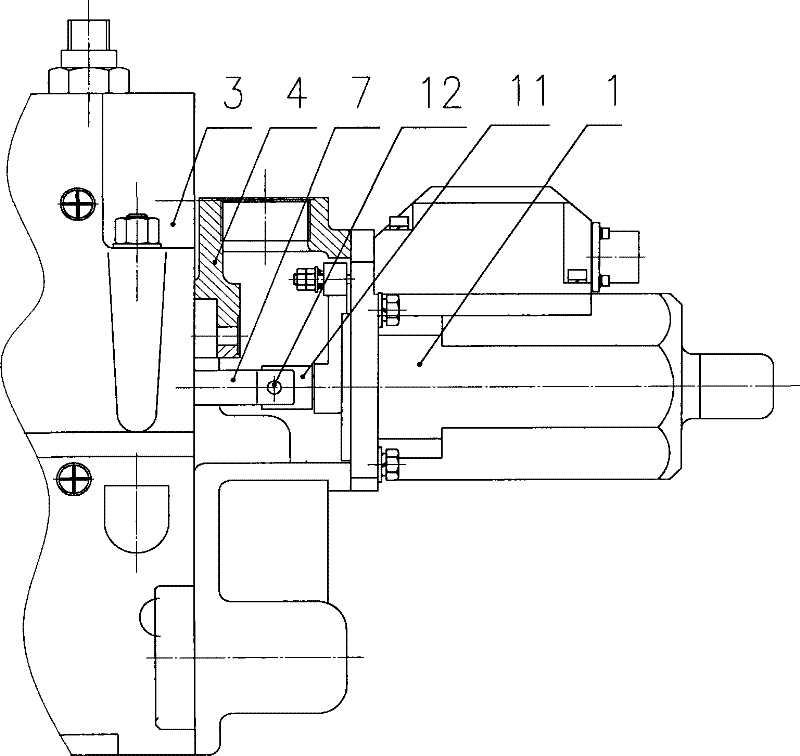

[0012] Below in conjunction with accompanying drawing, preferred embodiment of the present invention is described further:

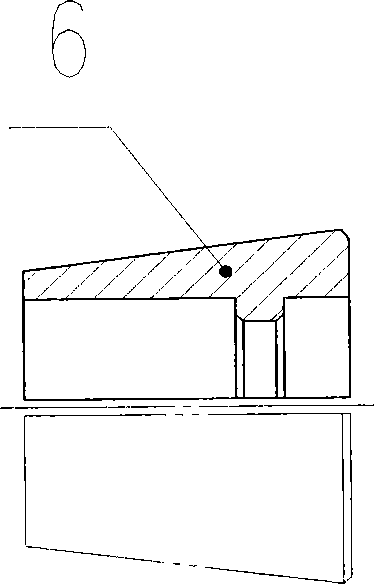

[0013] Such as figure 1 As shown, this structure includes an intermediate body 4, a spring plate 5, a block 6, a return spring 8, a ball nut 9 on the actuator 1, and a gear rod 7 on the fuel injection pump 3, etc., and one end of the return spring 8 is supported in the middle On the body 4, the other end is pressed on the spring disk 5. The inner hole of the spring disk 5 is a tapered hole with a flange at the end. The spring plate 5 and the rack bar 7 are connected by two blocks 6, the block 6 and the spring plate 5 are connected by a tapered surface, and the block 6 and the rack bar 7 are connected by a slot. The gear rod 7 cuts a rectangular ring groove on the circumference for the end of the cylinder, and the end face is a circular plane. Such as figure 2 As shown, the clamping block 6 is composed of two pieces, the shape of which is a circular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com