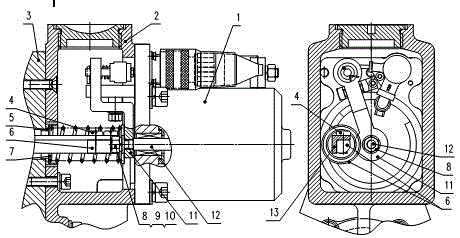

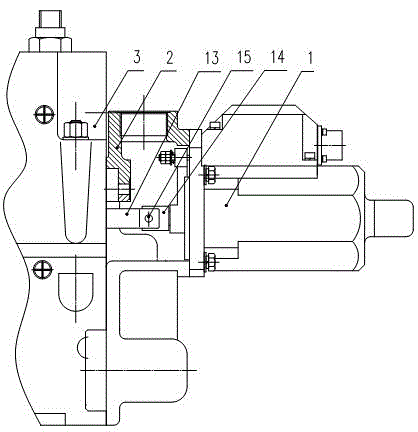

Offset connection structure between actuator and fuel injection pump

A connection structure, fuel injection pump technology, applied in the direction of fuel injection pump, fuel injection pump, fuel injection device, etc., can solve the problems of complex assembly process, easy jamming, asynchronous actuator and fuel injection pump gear rod, etc. To the effect of compact connection and reduction of axial dimension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, preferred embodiment of the present invention is described further:

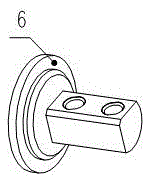

[0012] Such as figure 1 As shown, this structure includes intermediate body 2, screw 4, tray 5, connection plate 6, return spring 7, nut 8, spring washer 9, flat washer 10, lever 11 on actuator 1, push-pull rod 12, fuel injection pump 3 on the gear bar 13 etc. composition, back-moving spring 7 one end supports on the fuel injection pump 3 gear bar hole, and the other end is pressed on the connection plate 6. The connection plate 6 and the gear bar 13 are connected by two screws 4, the tray 5 and the return spring 7 are positioned on the outer edge of the tray 5, and the connection plate 6 and the return spring 7 are positioned by the inner protrusion of the connection plate 6. Push-pull rod 12 heads are external threads, and there are step shafts at the root of the thread, and there is a light hole in the center of the driving rod 11 big heads, which ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com