Multi-curved trough solar heat collection system

A trough solar, multi-curved surface technology, applied in solar heating systems, solar collectors, solar thermal energy, etc., can solve the problems that restrict the development of trough line focusing systems, the difficulty of mass production of melting sealing technology, and the poor sealing strength. To the requirements and other issues, to achieve the effect of improving wind resistance, simple manufacturing process and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

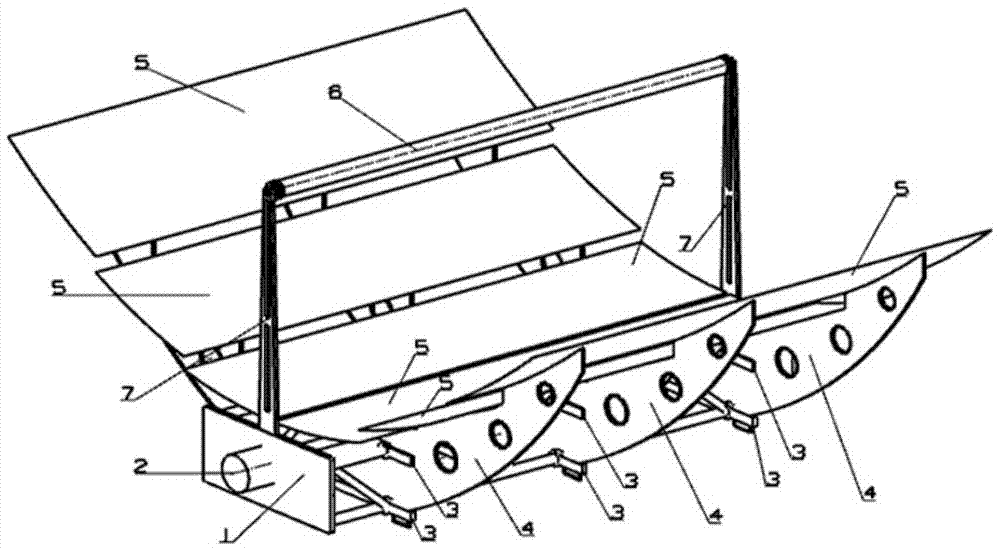

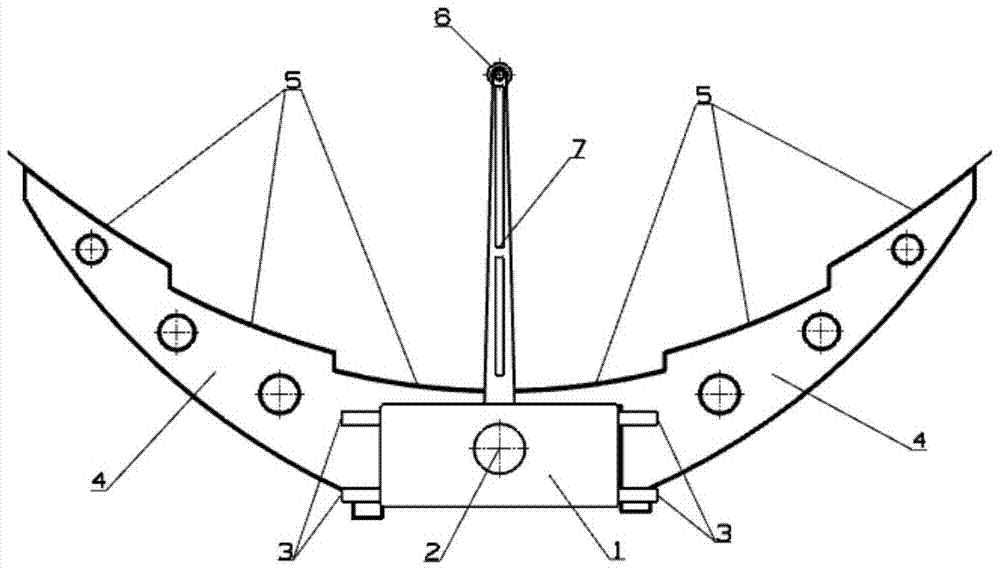

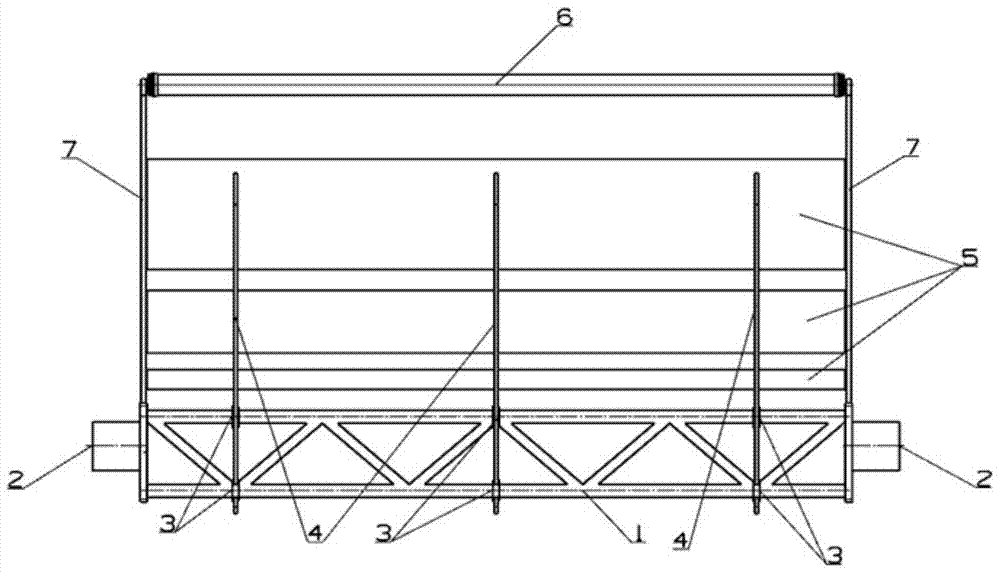

[0026] A multi-curved trough solar heat collection system includes: torque support 1, rotating shaft 2, formwork holder 3, steel formwork 4, arc-shaped tempered glass reflector 5, ceramic sealing straight-through metal-glass vacuum heat collection tube 6, and the support rod 7 of the heat collecting element. Its characteristics are: the torque bracket 1 of the box-type truss structure is used to resist the torsion and bending caused by strong wind and gravity, the rotating shaft 2 is fixed at both ends of the torque bracket 1, and the template holder 3 is installed on both sides of the torque bracket 1. On both sides of the torque bracket 1, three pairs of steel templates 4 are installed through the fixture 3. On the three pairs of steel templates 4, arc-shaped tempered glass reflectors 5 with different radii of curvature are installed. The space of these reflectors is The positions are fitted on three confocal but different focal length parabolas to ensure that sunlight is re...

Embodiment 2

[0029] The structure of embodiment 2 is basically the same as embodiment 1, the difference is:

[0030]The ceramic sealed straight-through metal-glass vacuum heat collecting tube adopts the internal expansion type vacuum heat collecting tube. Engineering ceramics use silicon carbide ceramics.

Embodiment 3

[0032] The structure of embodiment 3 is basically the same as that of embodiment 1, the difference is that the concentrator part in the multi-curved trough solar heat collection system is a general component, and it can also replace the traditional parabolic concentrator, the difference is that in the concentrator On the focal line, straight-through metal-glass vacuum heat collectors are installed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com