Hydraulic coupling with freely regulated coupling direction

A hydraulic pipe joint, axial technology, applied in the direction of adjustable connections, pipes/pipe joints/fittings, passing elements, etc., to avoid twisting of hoses or too small bending radius, and to achieve the effect of easy docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

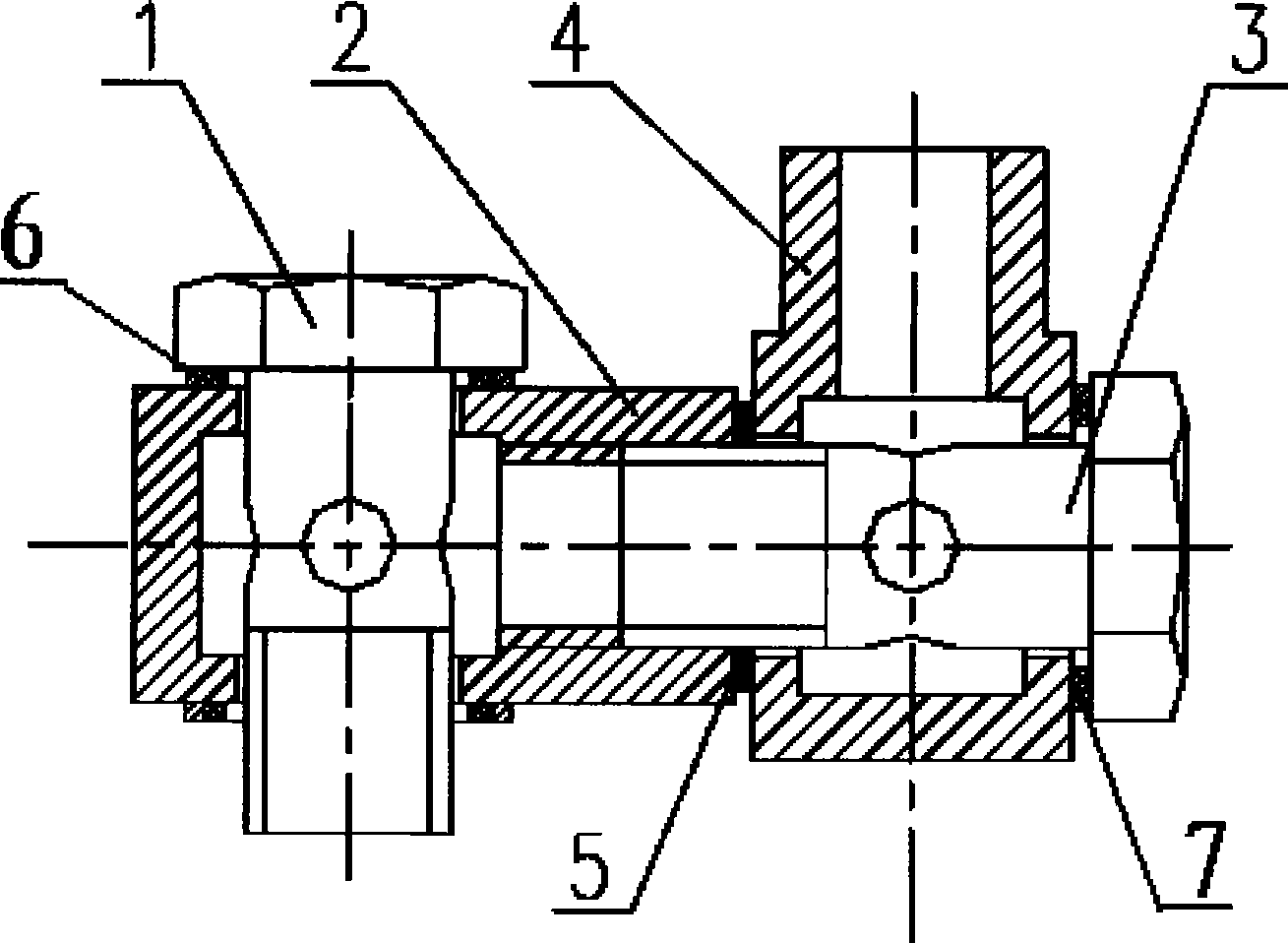

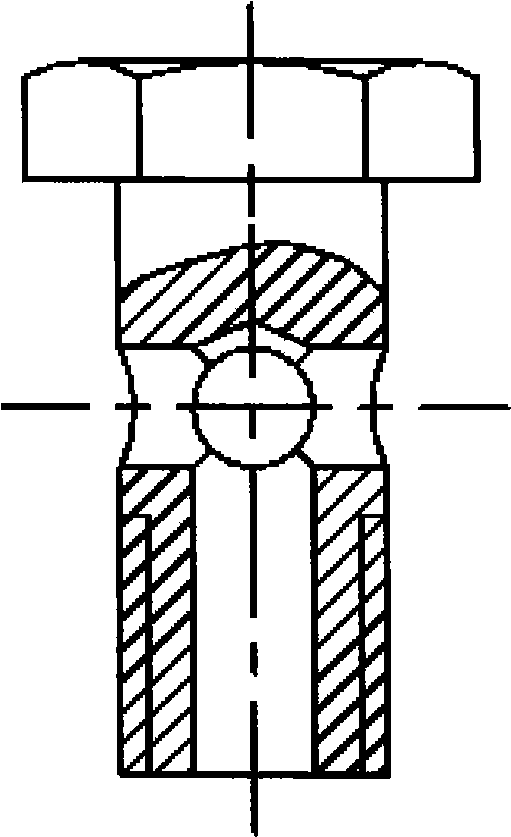

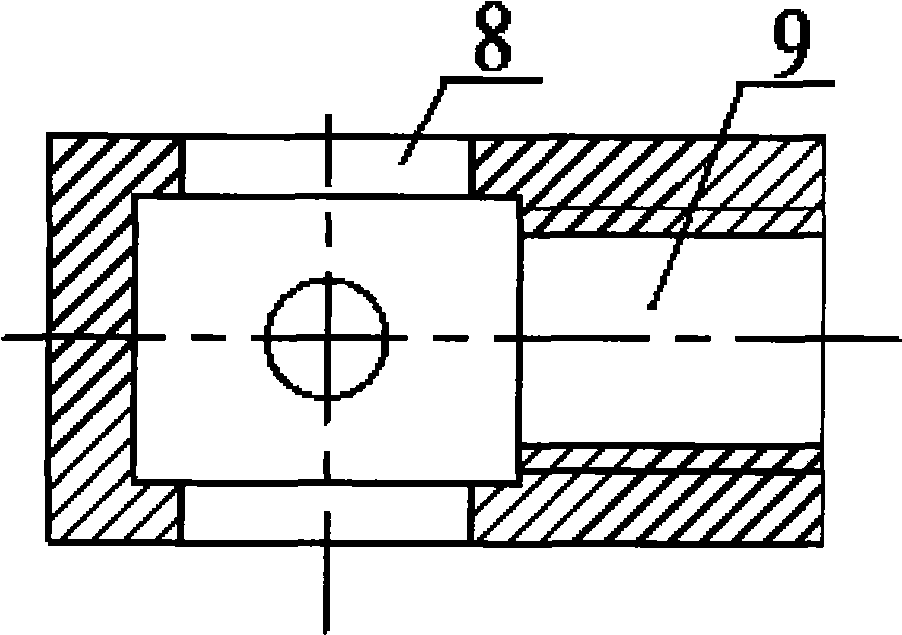

[0010] like figure 1 As shown, a hydraulic pipe joint of the present invention that can adjust the connection direction arbitrarily consists of a hollow bolt 1, a rotary body 2, a hollow bolt 2 3, a rotary body 4, and several combined sealing washers 5, 6, 7, etc. composition. like figure 2 As shown, the hollow bolt 1 has fluid passages both axially and radially. like image 3 As shown, the rotary body-2 is processed with a through hole 8, and there is a connecting oil port 9 in the radial direction, and there is a thread in the oil port. The structure of the hollow bolt two 3 is basically the same as that of the hollow bolt one 1, and the structures of the second rotator 4 and the first 2 of gyratory are also similar. The external thread of the hollow bolt two is matched with the internal thread of the rotary body one connecting the oil port 9. The first rotary body can rotate 360 degrees around the hollow bolt one, and the second rotary body can rotate 360 degrees ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com