Outer prestress system and its construction process

An external prestressing and system technology, applied in the direction of transmission elements or pulley ropes or cables, structural elements, building components, etc. problems such as the service life of the cable body, to achieve the effect of uniform force, easy installation, and stable performance under working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

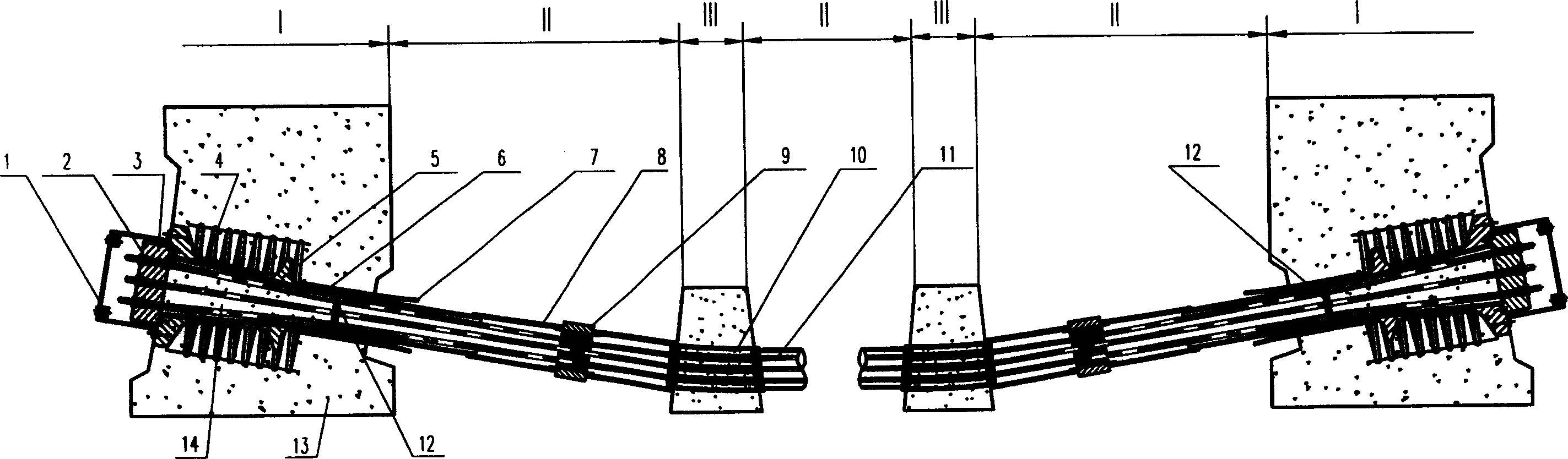

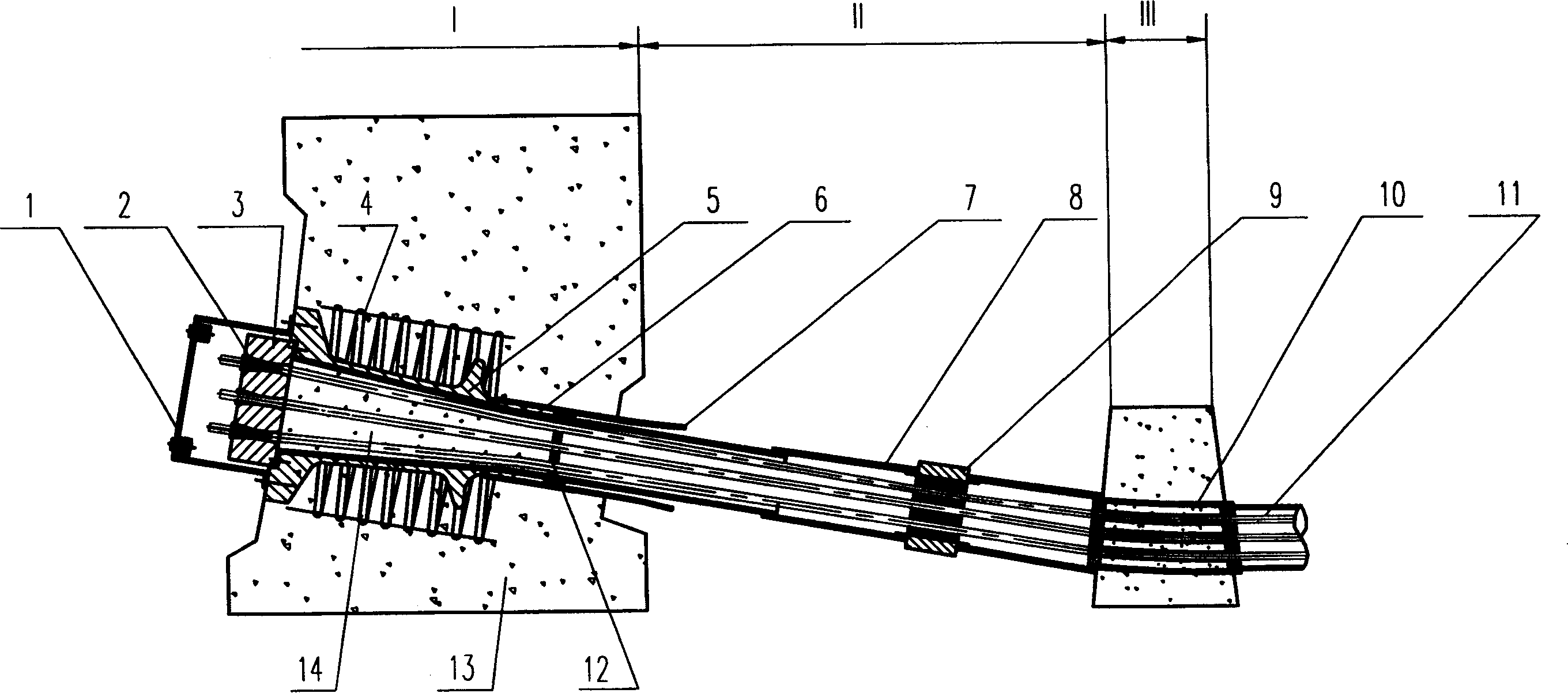

[0047] An external prestressing system, including two anchor segments I at both ends, two steering segments III, and three free segments II between the anchor segments I and steering segments (see figure 1 , figure 2 );

[0048] The anchor segment I is composed of an anchor head and an anchor area. The anchor head part includes a cable body sealing cover 1, an anchor plate 3, and a clip 2. The anchor area includes a spiral rib 4, an anchor backing plate 5, an inner Bushing 6, embedded pipe 7, grouting material 14, sealing plate 12;

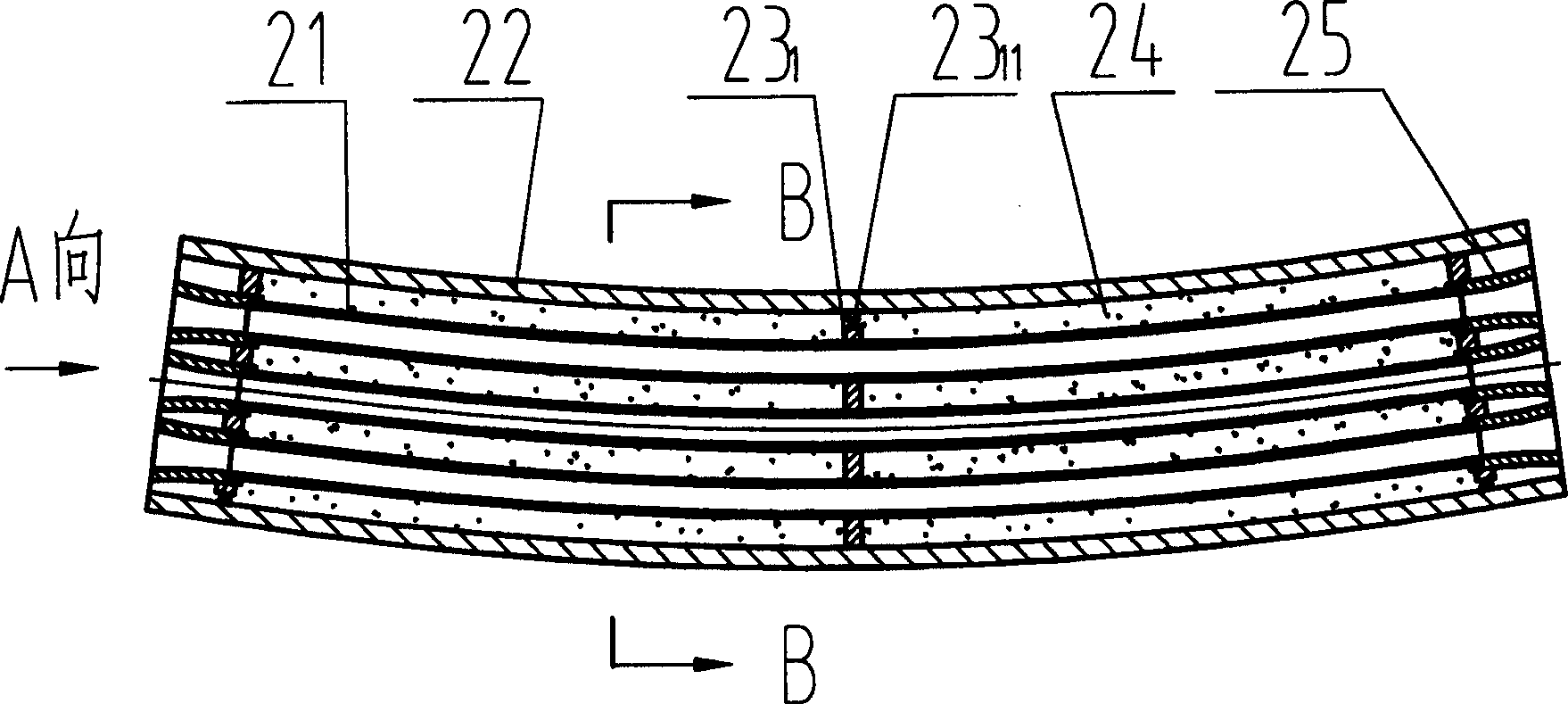

[0049] The free section II is composed of a cable body 11 covered with a protective jacket 8, and the cable body 11 uses high-strength steel strands as raw materials for enhanced anti-corrosion treatment of epoxy full-sprayed unbonded reinforcement as prestressed reinforcement The protective jacket 8 can be a PE sheath, steel pipe or PVC pipe. The protective jacket 8 of the free section of the external prestressing system adopts different pipes...

Embodiment 2

[0054] An external prestressing system, the basic structure of which is the same as that of Embodiment 1, the difference is that the anchor segment I is a movable bush type clip anchor, and the anchor head part also has a gasket ring 27, There is a replaceable protective tube 28 in the anchor backing plate 5, and the large end of the replaceable protective tube 28 stretches out from the anchor backing plate 5. The replaceable protective tube 28 is a transition fit, the replaceable protective tube 28 can move axially, the gasket ring 27 is fixed on the end face of the anchor plate 5 by screws, and the sealing plate 12 is installed on the small end of the replaceable protective tube 28 (see Figure 8 ), the replaceable protective tube 28 is made of metal materials such as steel plates, aluminum plates or plastic materials such as polytetrafluoroethylene or polyethylene or high-density polyethylene.

Embodiment 3

[0056] An external prestressing system, the basic structure of which is the same as that of Embodiment 1 or Embodiment 2, except that the shock absorber 9 installed at the appropriate position of the cable body of the free segment II is a single compression damper Vibrator (see Fig. 9, Fig. 10); This shock absorber consists of two semicircular outer sheaths 29 1 、29 2 , 6 pieces of damping spacers 30 1 、30 2 、......30 6 , sheath ears 31, and connecting bolts 33, the damping gasket 30 in the middle 2 、30 3 、30 4 、30 5 There are arc-shaped grooves on both sides, and the arc-shaped grooves of two adjacent gaskets are butted to form a circle, and the shock-absorbing gasket 30 close to the outer sheath 1 、30 6 There is an arc-shaped groove on one side, and an arc-shaped groove matching the circular outer sheath on the other side. Two semicircular outer sheaths 29 1 、29 2 The butt joint is connected into one body by bolts 33 and nuts 32, and the damping pads can be made of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com