Cloth tensioning apparatus in embroidering machine

A technology of tensioning device and embroidery machine, applied in the mechanism of embroidery machine, embroidery machine, feeding device, etc., can solve the problems of difference, deterioration of sales force, deformation of embroidered patterns, etc., and achieve high-quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Reference will now be made in detail to the preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts. In the following description, in order to facilitate a better understanding of the present invention, detailed descriptions of known prior technologies or functions will be omitted.

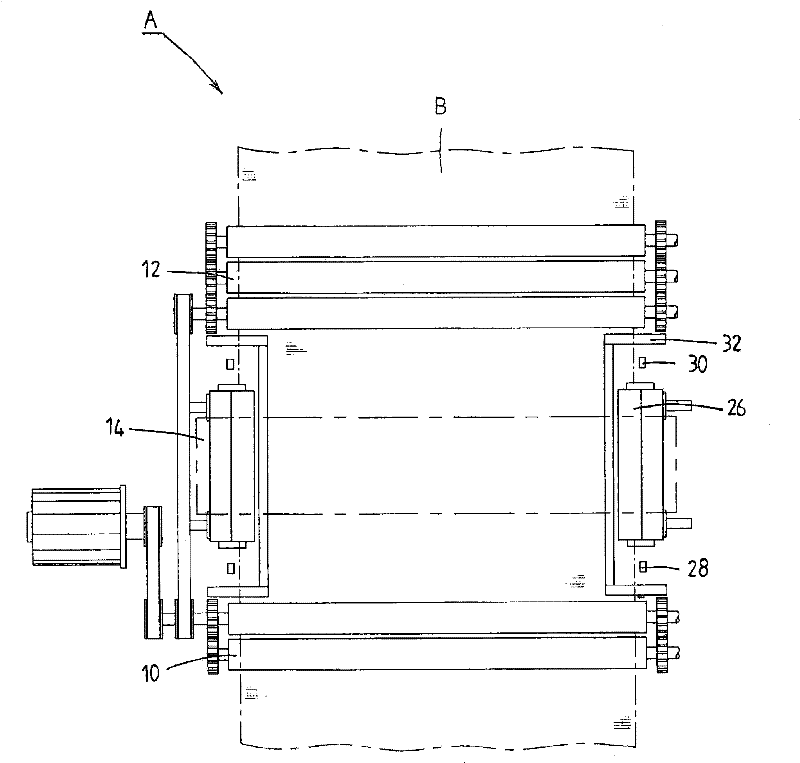

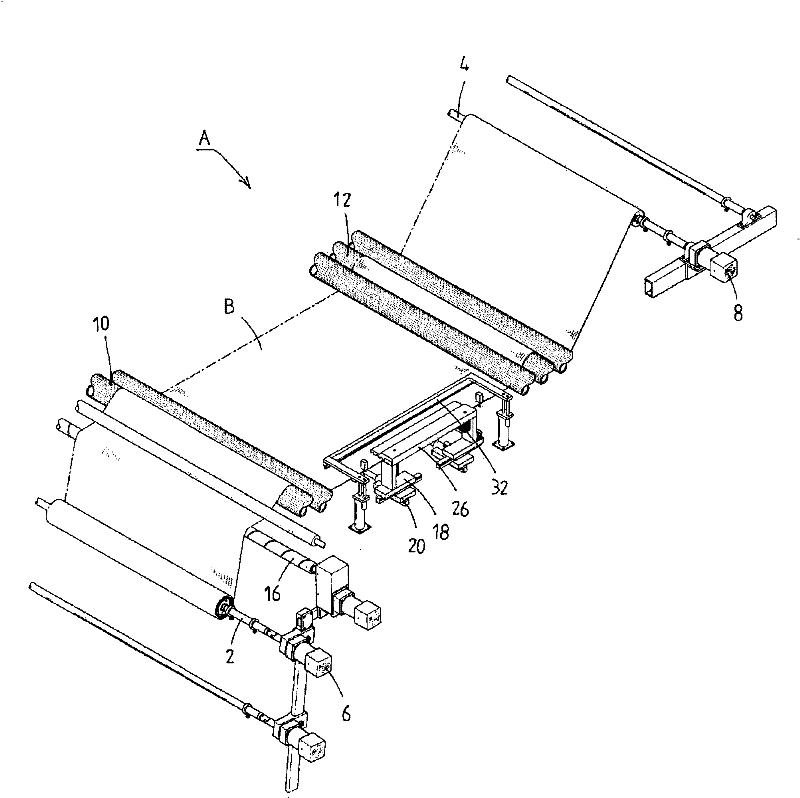

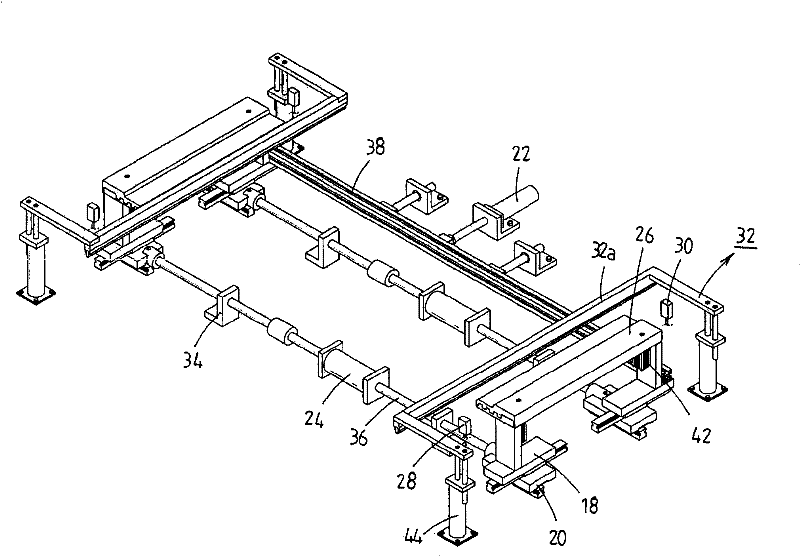

[0017] figure 1 and figure 2 These are a plan view and a perspective view illustrating an embroidery machine according to the present invention, respectively. Such as figure 1 and figure 2 As shown, the embroidery machine A includes a cloth supply roller 2, a cloth winding roller 4, torque motors 6 and 8 and a head 14, and the torque motors 6 and 8 are used to rotate the cloth supply roller 2 and the cloth winding roller 4 respectively, The head 14 is disposed between the front delivery roller 10 and the rear delivery ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com