Duplex head milling machine for processing sole mould chamfering

A double-head milling machine and shoe sole mold technology, applied in the field of machinery, can solve the problems of low chamfering accuracy, low work efficiency, inconvenient processing, etc., and achieve the effects of high chamfering accuracy and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

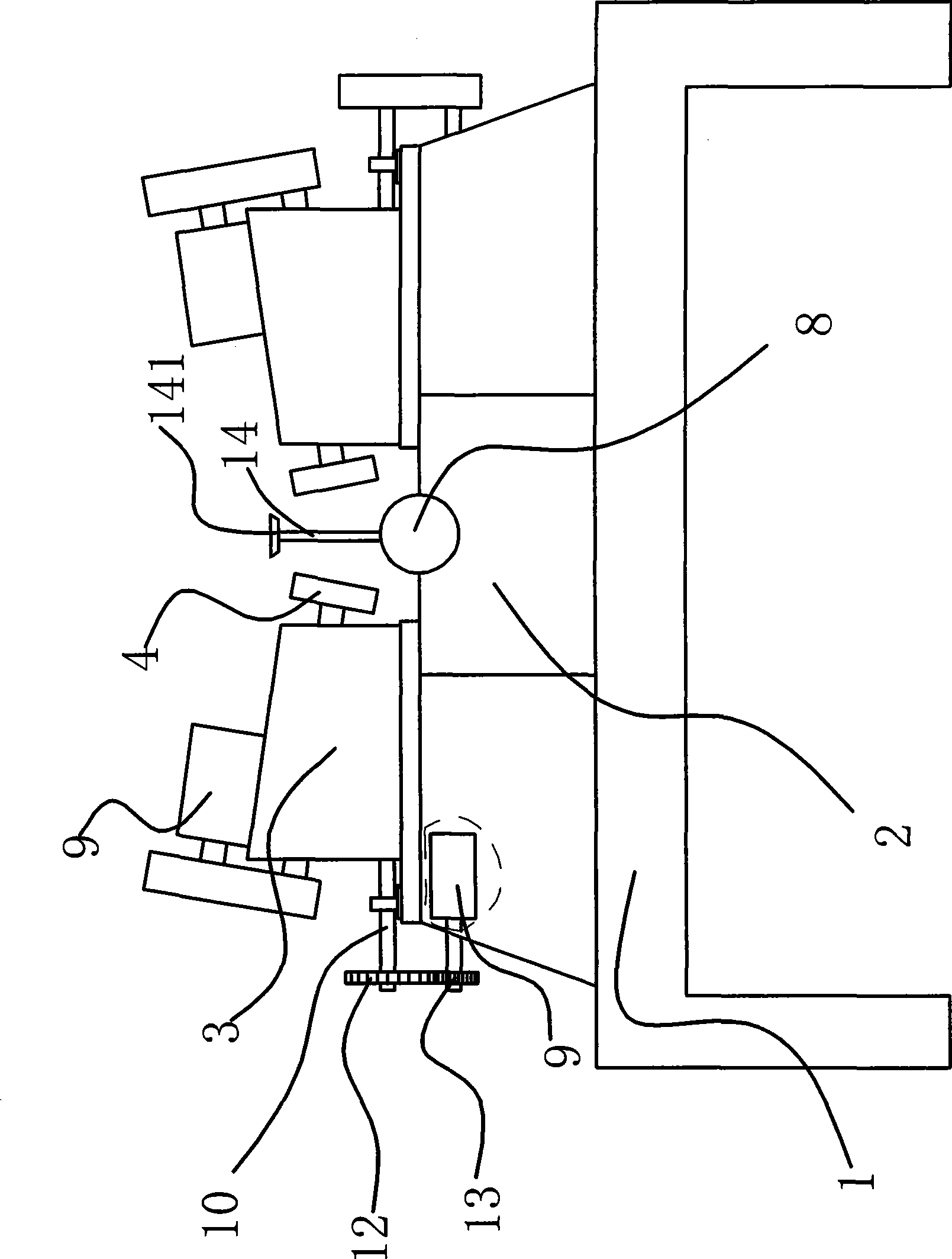

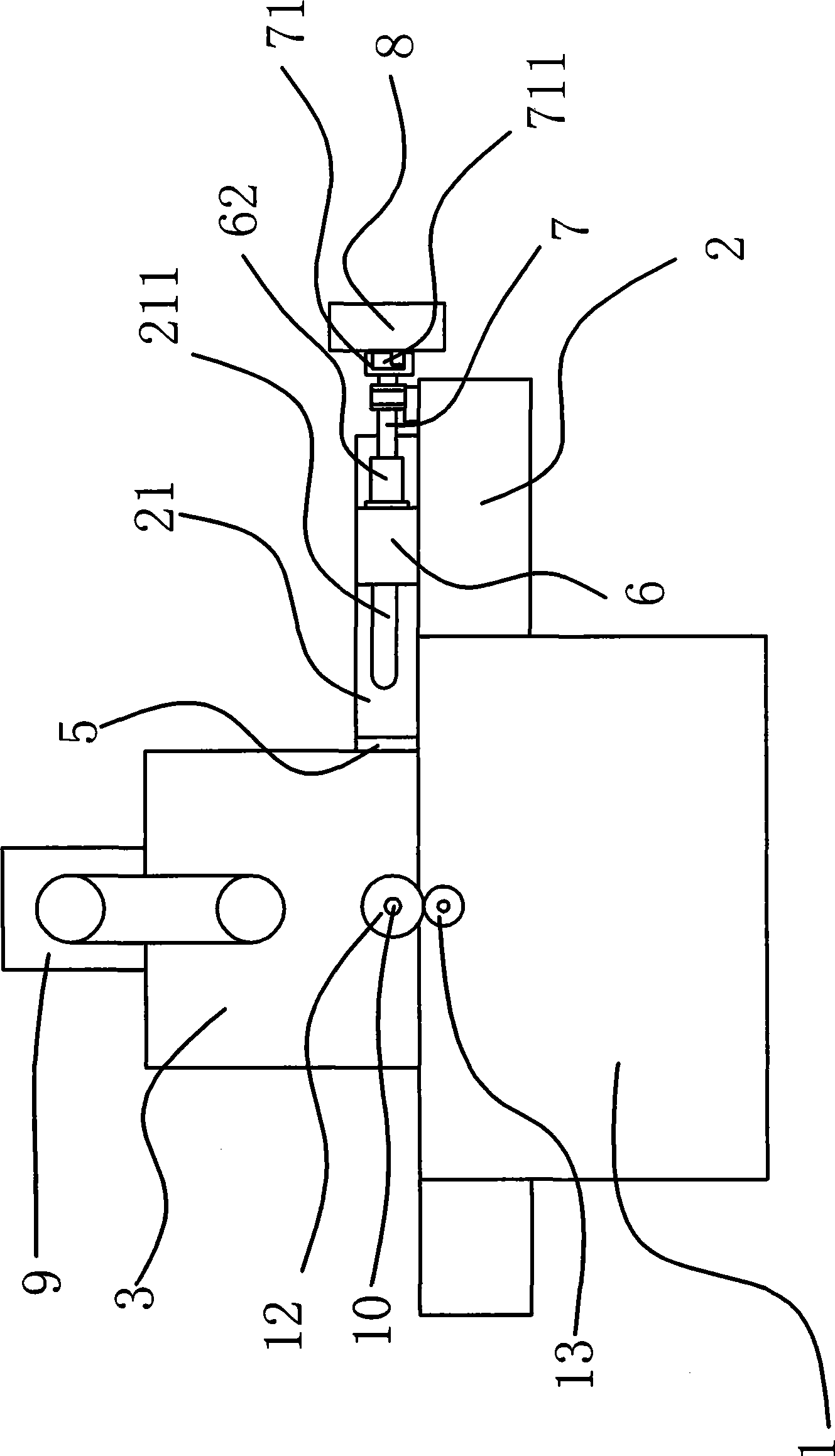

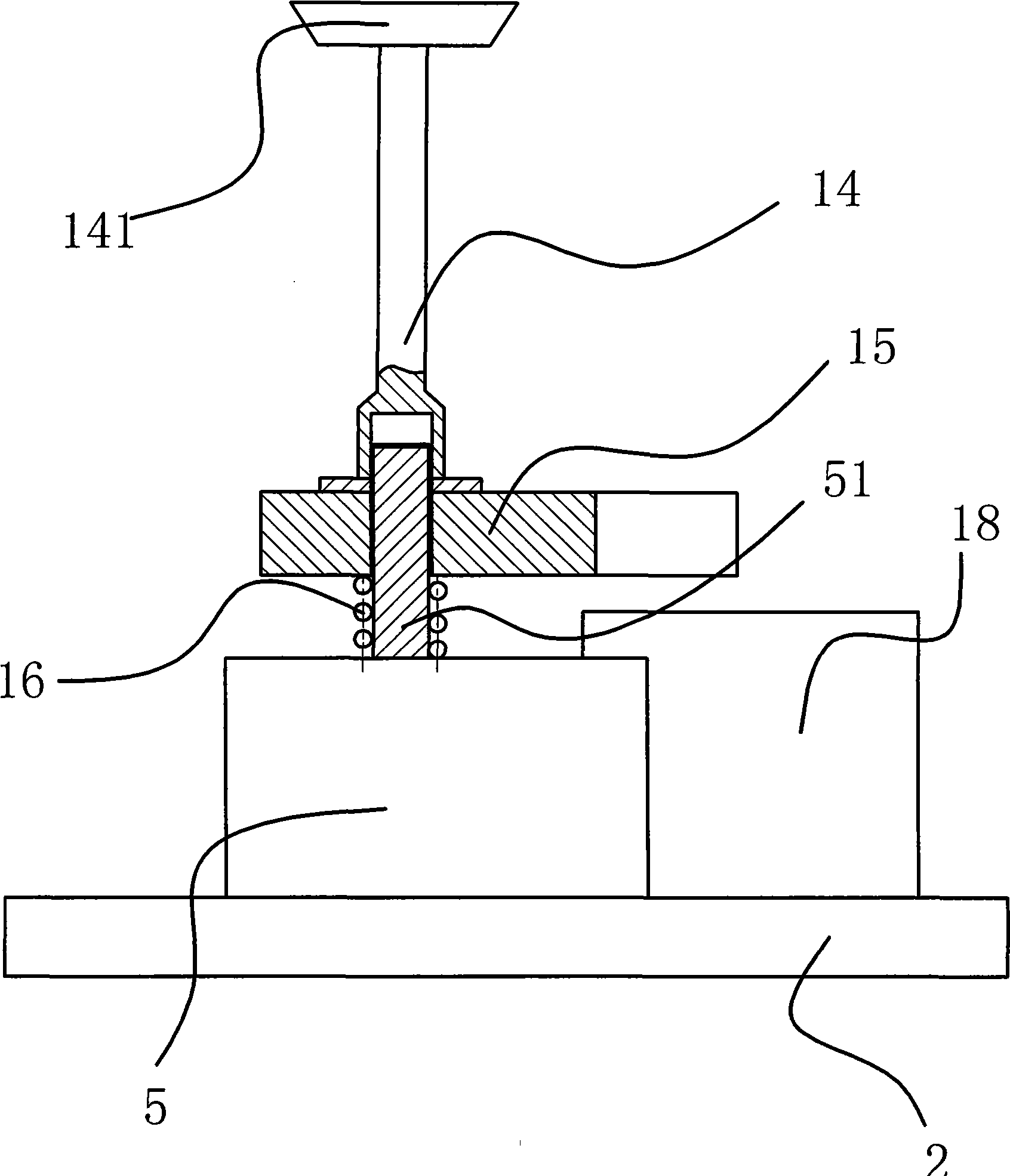

[0039] Such as figure 1 , figure 2 and Figure 4As shown, the double-headed milling machine used to process the chamfering of the sole mold includes a frame 1 and a workbench 2 that can move back and forth on the frame 1, and the workbench 2 is provided with a clamping device for clamping the mold 18. Two sets of milling units are symmetrically distributed on both sides of the clamping device, and the milling units on both sides of the workbench 2 are arranged in one-to-one correspondence. Each milling unit includes a machine base 3 and a milling cutter 4 obliquely arranged on the machine base 3 And the power mechanism for driving the milling cutter 4 to rotate is provided with an adjusting device capable of adjusting the distance between two opposite supports 3 between each support 3 and the frame 1 . The milling cutter 4 is obliquely arranged on the support 3 and can better process the chamfering of the sole mold 18 to make it more accurate.

[0040] Such as figure 1 an...

Embodiment 2

[0047] The content of embodiment 2 is basically the same as embodiment 1, and the difference is that the drive mechanism is a motor one and a nut seat 62 fixedly connected to the positioning part two 6, and the motor one is fixed on the workbench 2 and the motor one rotating shaft and the nut seat 62 connected. In this way, the second positioning piece 6 can also be driven to make the slider 61 of the second positioning piece slide in the bar-shaped opening 211 on the baffle plate 21 .

Embodiment 3

[0049] The content of embodiment 2 is basically the same as that of embodiment 1, the difference is that the driving mechanism is an air cylinder, the air cylinder is fixed on the workbench 2 and the main shaft of the air cylinder is connected with the positioning member 2 6 . This can also drive the second positioning piece 6 to make the slider 61 of the second positioning piece 6 slide in the bar-shaped opening 211 on the baffle plate 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com