Flexible assembly digital fixture device

A flexible assembly and rack device technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of occupying a large plant area and space, restricting the development of the aircraft manufacturing industry, and lengthening the aircraft research and development cycle, and achieve a compact structure. , The effect of rapid shape adjustment and strong versatility

Inactive Publication Date: 2010-12-01

SHENYANG AIRCRAFT CORP +1

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The traditional aircraft assembly adopts a one-to-one model frame card board chess style. Each model frame corresponds to a set of card boards, and the positions of the ends of the card boards connected to the model frame are fixed. A set of model frames can only be used for An assembly object, which requires the manufacture of a large number of assembly frames in the process of aircraft production preparation, makes the research and development cycle of the aircraft longer, the cost becomes higher, and occupies a very large area and space of the factory building, which seriously restricts the development of my country's aircraft manufacturing industry. develop

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

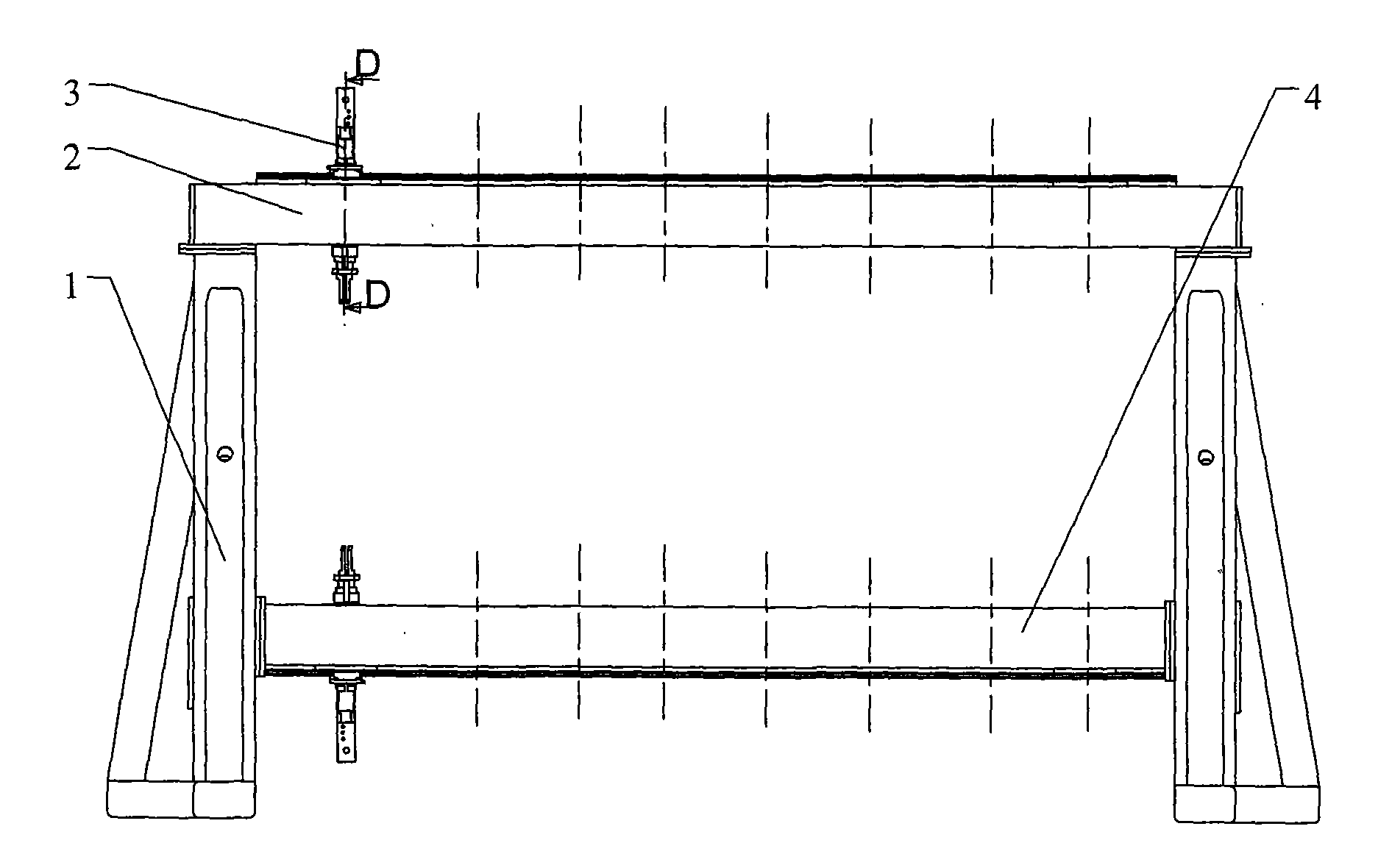

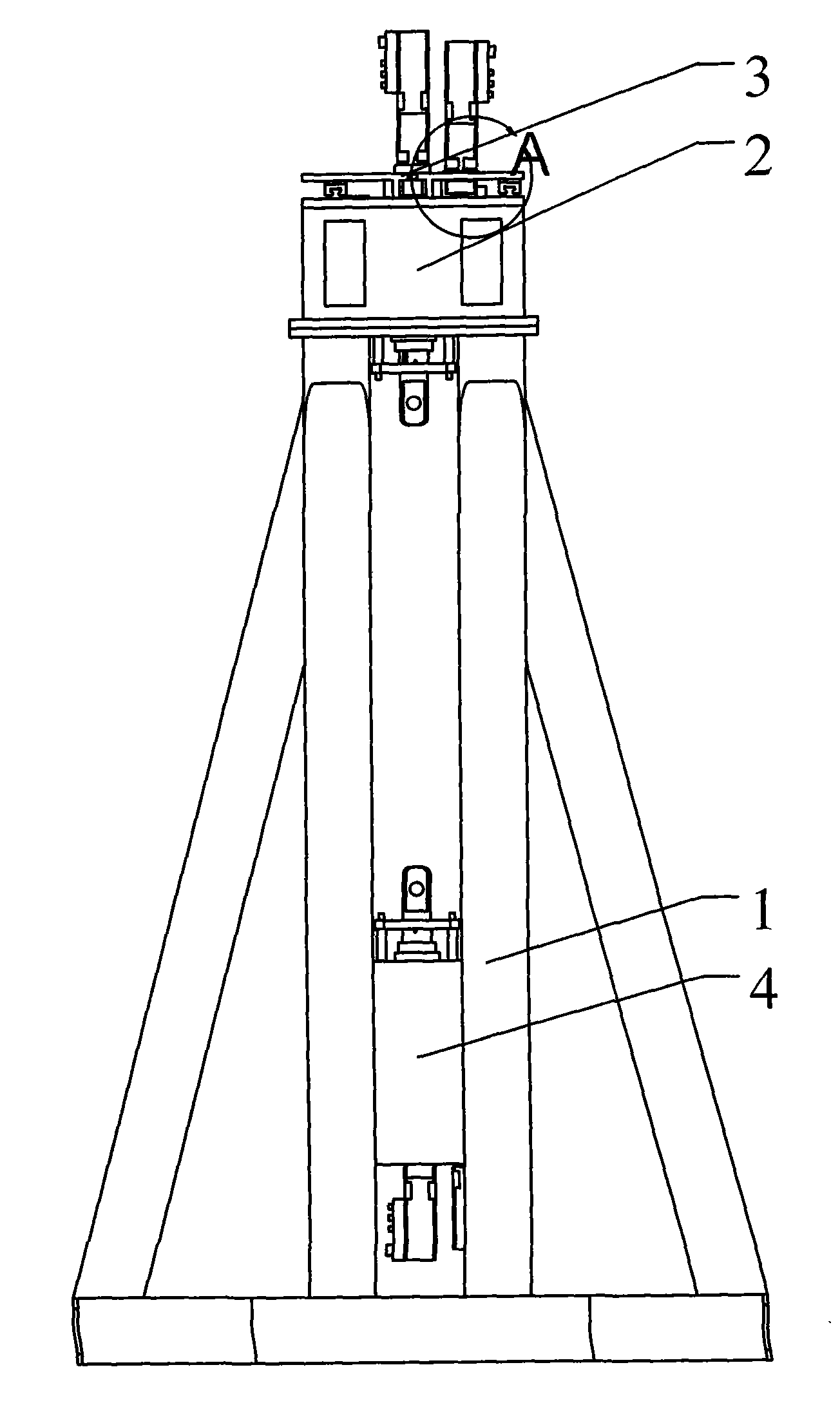

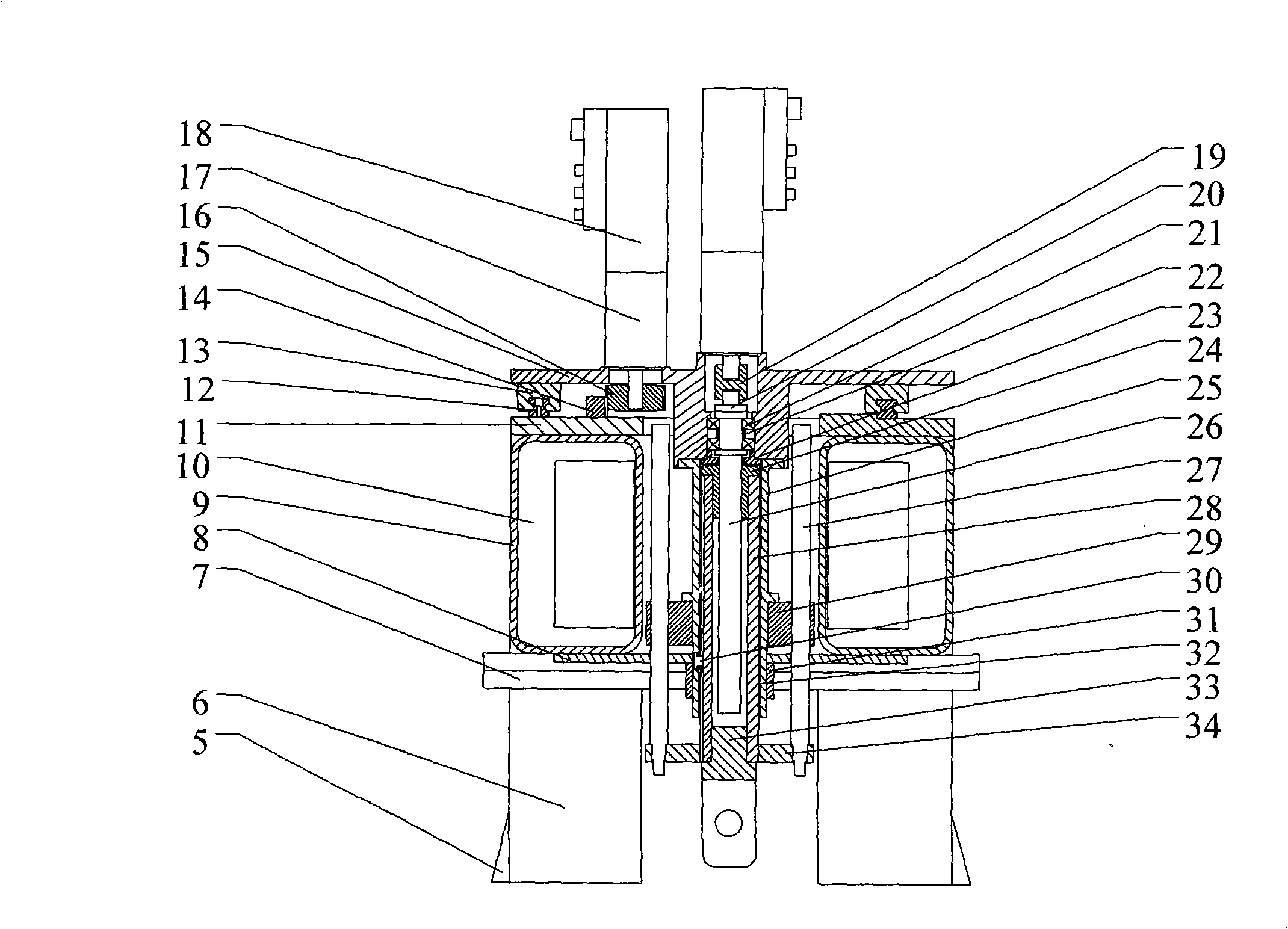

The invention relates to a digital flexible assembly frame device, which consists of a frame framework and 16 mobile shape adjusting units, wherein the frame framework is formed by assembling an upper beam component, a lower beam component and an upright post component; a guide rail, a slider and a rack are arranged on the frame framework; the number of the mobile shape adjusting units is 16, wherein 8 mobile shape adjusting units are arranged on the upper beam component, and 8 mobile shape adjusting units are arranged on the lower beam component; the mobile shape adjusting units on the lowerbeam component and the mobile shape adjusting units on the upper beam component are symmetrically arranged; and each mobile shape adjusting unit is connected with a pair of sliders in a mode of screwed joint and comprises a mobile bracket, a motor, a speed reducer, a coupler, a lead screw, an angular contact bearing, a copper sleeve, a guide rod sleeve and other parts. The mobile shape adjusting units are core components of the digital flexible assembly frame device, and free shape adjustment in two directions of assembly points is realized by the mobile shape adjusting units. The digital flexible assembly frame device has the advantages of quick shape adjustment, high precision, good openness, strong universality and simple and reliable structure, and realizes assembly of various wall board parts with one frame in aircraft assembly.

Description

A flexible assembly digital jig device technical field The invention relates to a flexible assembly digital jig device, which is used for the assembly of aircraft panel parts and belongs to the field of aircraft manufacturing and assembly. Background technique Aircraft assembly is a complicated process with relatively high technical requirements. Thousands of parts must be accurately positioned, connected, and assembled, and the workload is very heavy. The traditional aircraft assembly adopts a one-to-one model frame card board chess style. Each model frame corresponds to a set of card boards, and the positions of the ends of the card boards connected to the model frame are fixed. A set of frame frames can only be used for An assembly object, which requires the manufacture of a large number of assembly frames in the process of aircraft production preparation, makes the research and development cycle of the aircraft longer, the cost becomes higher, and occupies a very large ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23P19/00

Inventor 冯子明李东升孙金萍陶春君杜宝瑞王亮刘学武郑伟东欧阳刘凤贵

Owner SHENYANG AIRCRAFT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com