Beaker made from a paper material

A cup and paper-based technology, applied in carton/carton manufacturing machinery, paper/cardboard containers, container manufacturing machinery, etc., can solve the problems of coating tearing, plasticity, especially ductility limitation, and sealing effect, etc., to achieve The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

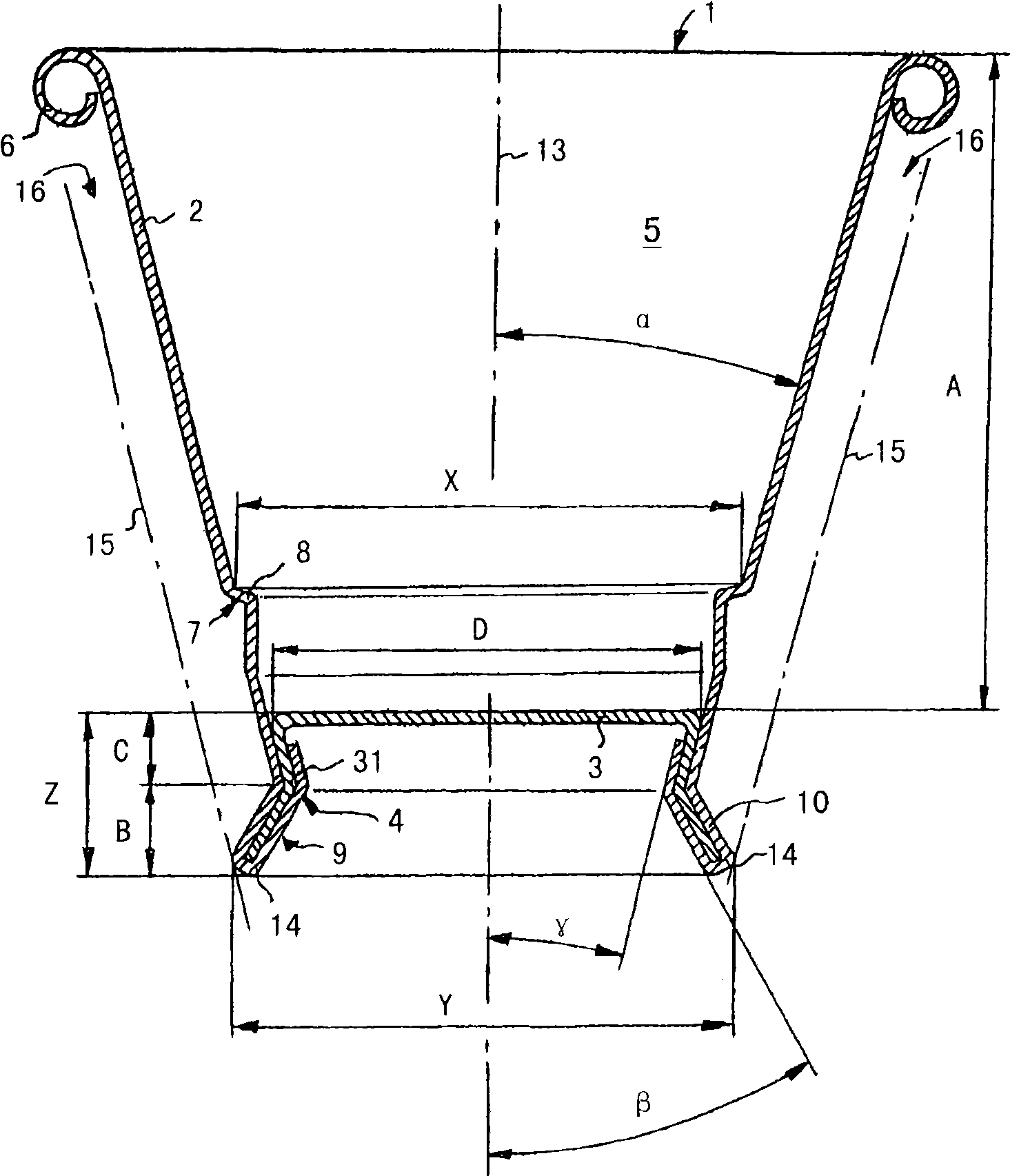

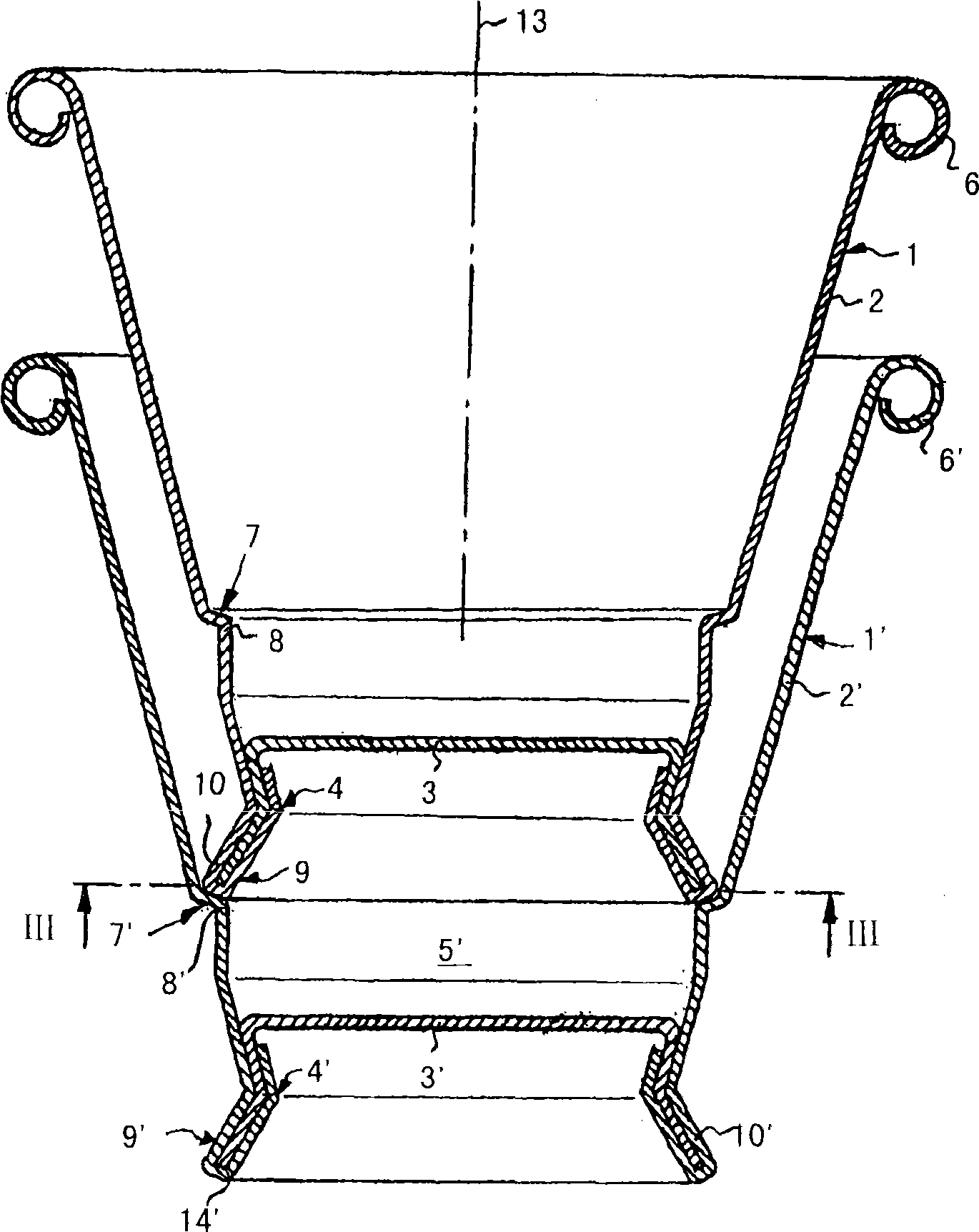

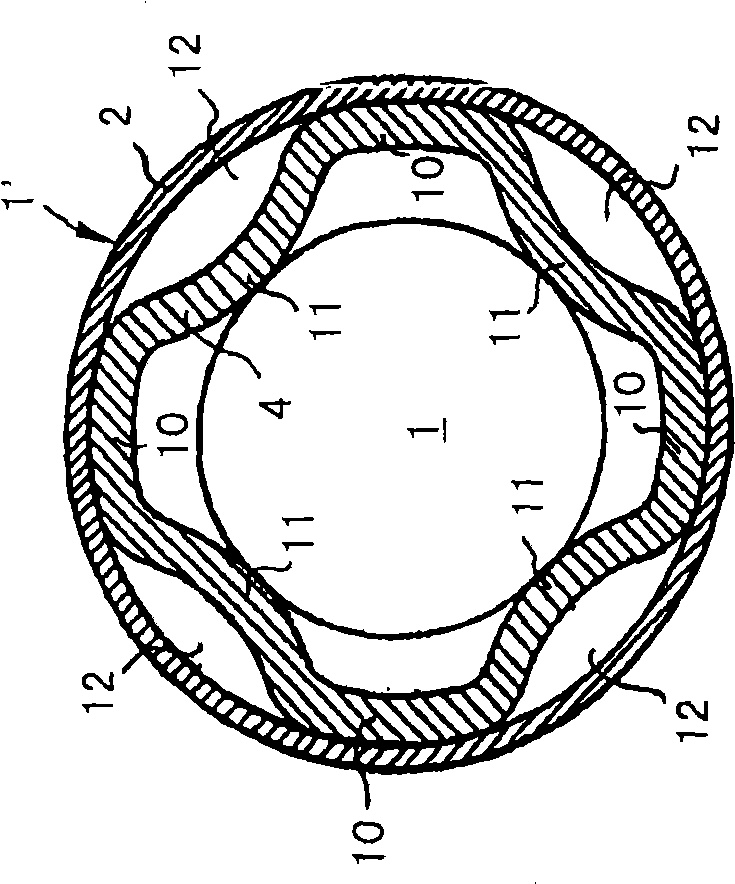

[0043] exist figure 1 The cup 1 shown in mainly comprises a conical cup shell 2 and a basin-shaped cup bottom 3 . The open side of the basin-shaped cup base 3 is arranged such that it faces away from the filling opening of the cup 1 . The cup base 3 is connected with its wall 31 to the cup shell 2 in a fluid-tight manner in the region of the smaller circumference of the cup shell 2 via a rim 4 . In the region of the rim 4 the material of the cup shell 2 is placed around the wall 31 of the cup base 3 and turned inwards. The cup shell 2 and the cup base 3 form a fillable interior 5 of the cup 1 . The fillable interior space 5 has a height A. On its upper edge, ie in the region of the larger circumference, the cup 2 delimiting the interior 5 has an outwardly beaded bead 6 surrounding the filling opening.

[0044] The "conical" nature of the cup 2 should be understood here in such a way that the cup 2 is figure 1 In the longitudinal section shown, it tapers from the curling m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com