Spiral flat-tube heat exchanger

A technology of flat tubes and heat exchangers, applied in the field of counterflow heat exchangers, can solve the problems of limited performance, large ratio of height to base, high thermal resistance, etc., and achieve the effect of great flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

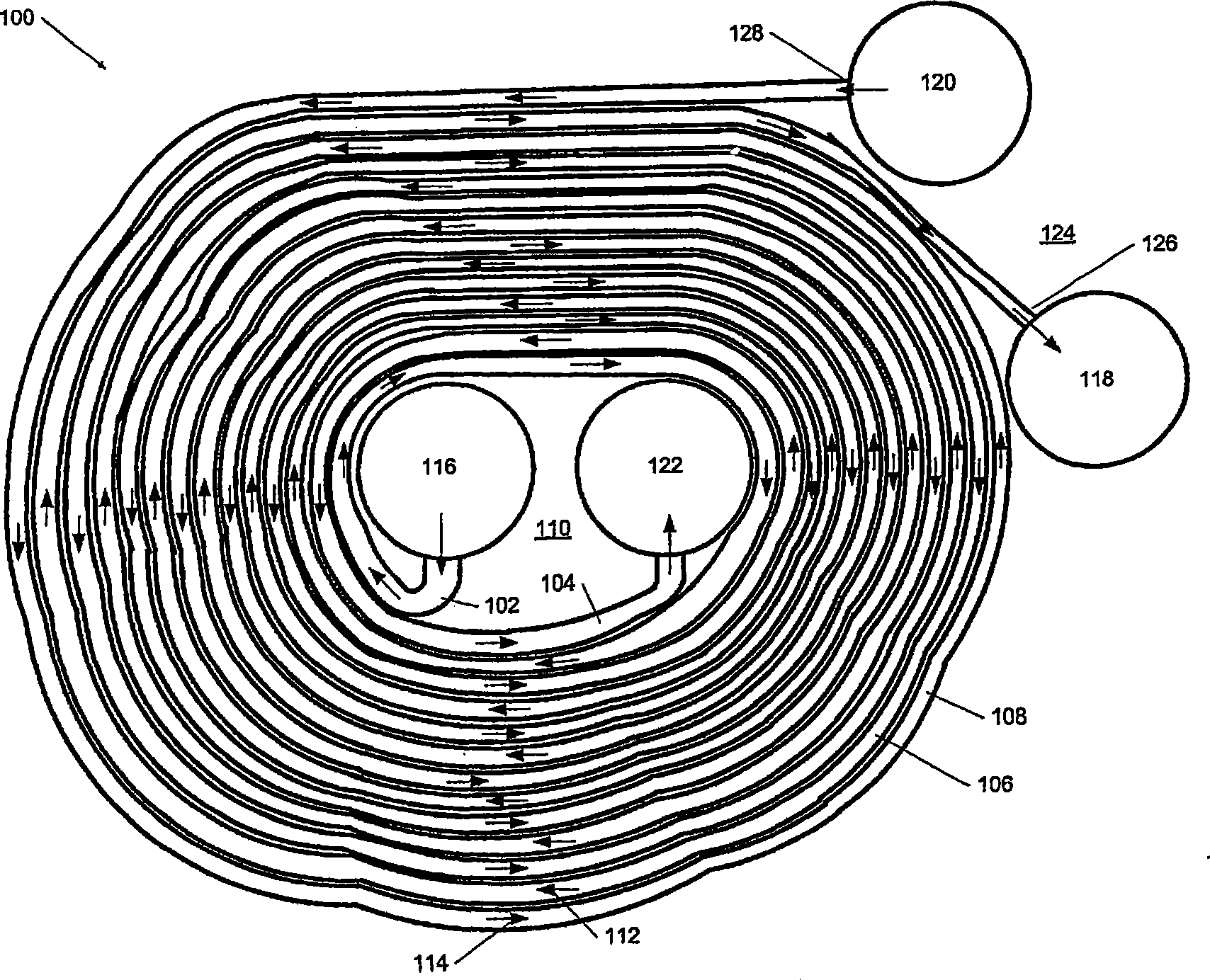

[0017] Please refer to the diagram, especially figure 1 , the embodiment of the spiral flat tube heat exchanger will be described below.

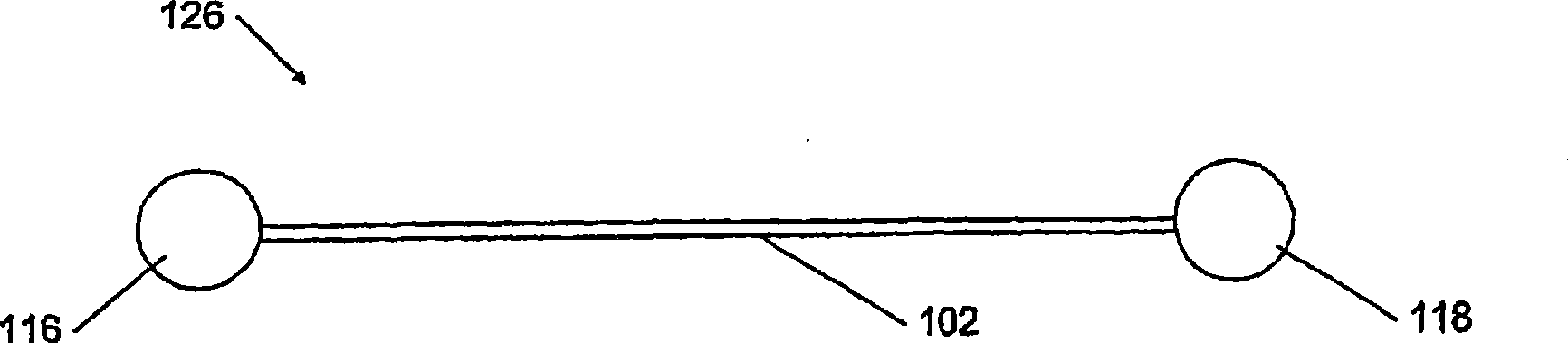

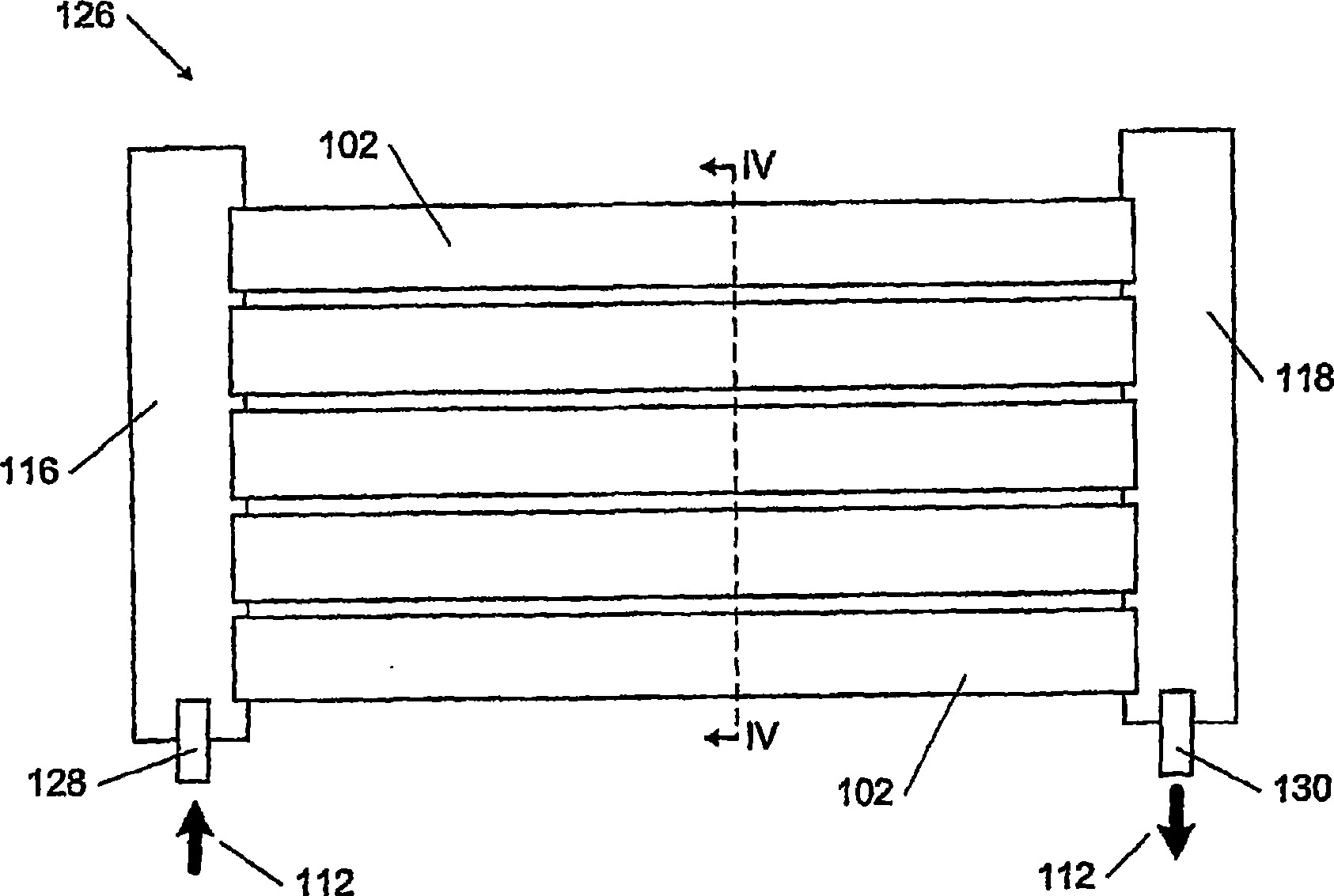

[0018] The heat exchanger 100 includes a first tube 102 and a second tube 104 . The first tube 102 is thermally coupled to the second tube 102, and the tube configuration forms an alternating helix, the helix preferably being approximately concentric. Substantially concentric means that the first helix 106 formed by the first tube 102 and the second helix 108 formed by the second tube 104 share a common central area 110 . For the purposes of this disclosure, the term helix refers to an object that surrounds a fixed central region with increasing distance from the region. A first working fluid 112 flows through the first tube 102 and a second working fluid 114 flows through the second tube 104 .

[0019] The first tube 102 and the second tube 104 are in thermal contact such that heat can be transferred between the first working fluid 112 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com