Foliage pressure-vacuum machine

A technology of blowing and sucking machines and leaves, which is applied in road cleaning, construction, cleaning methods, etc., and can solve problems such as product launch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

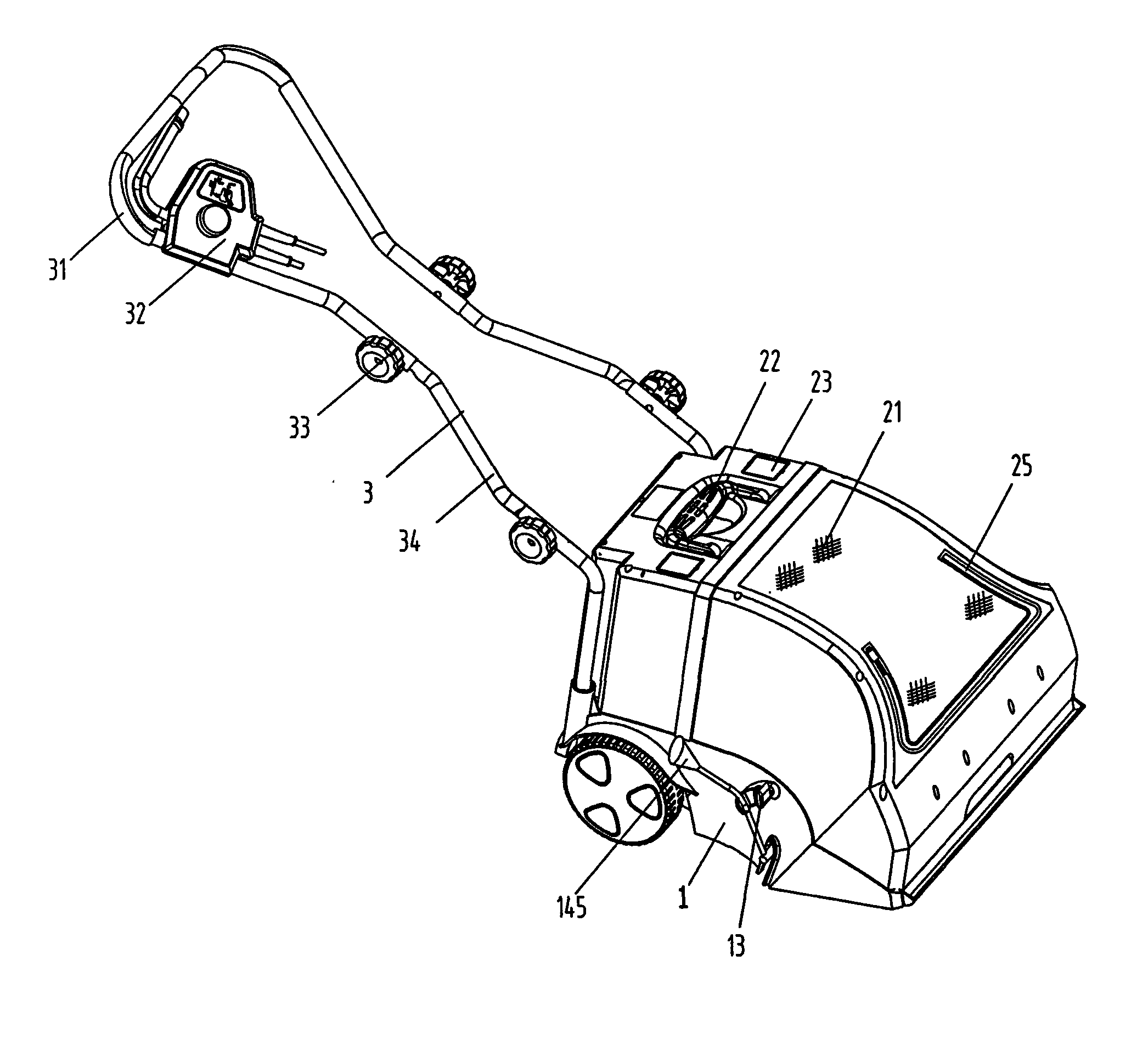

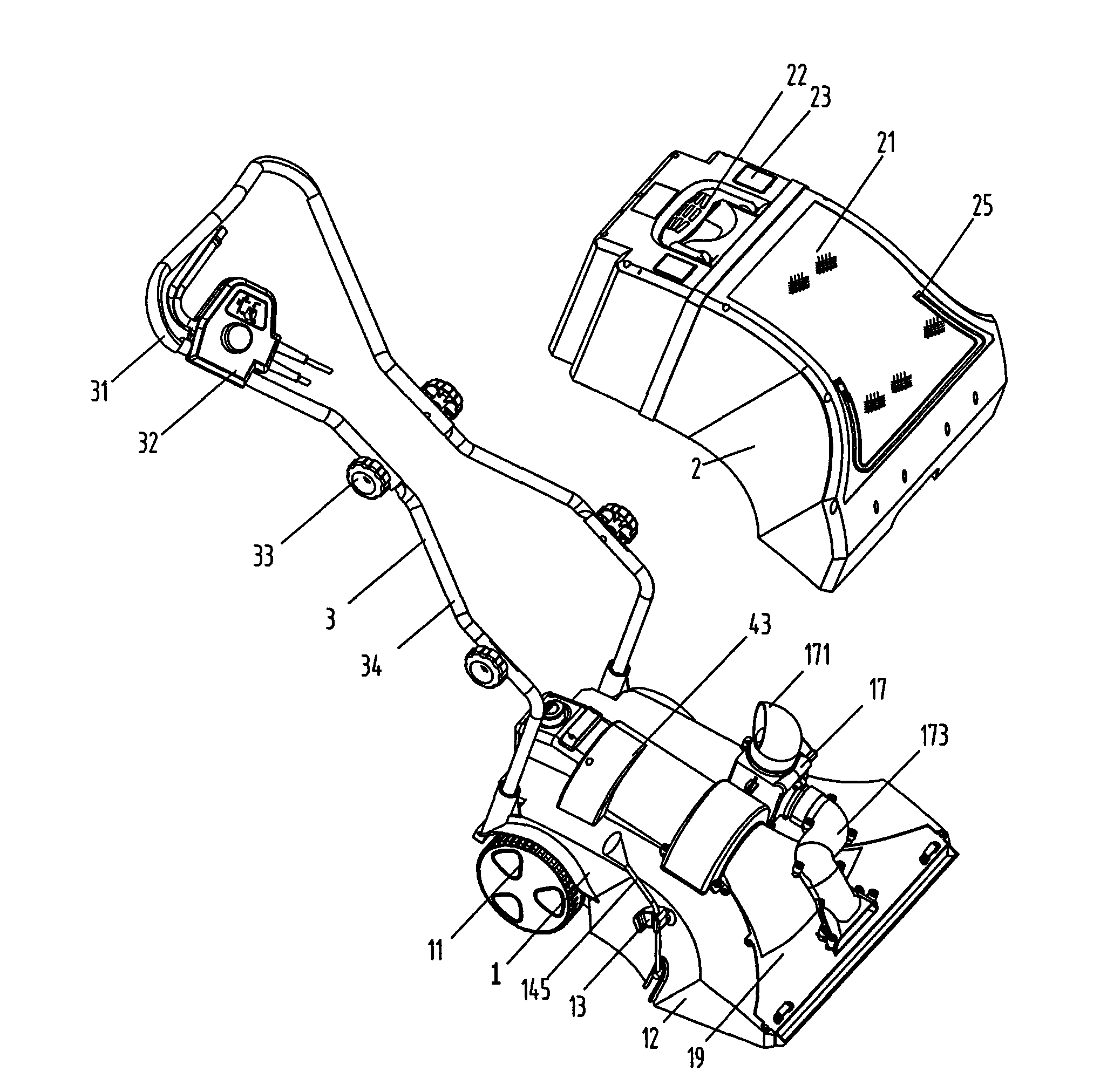

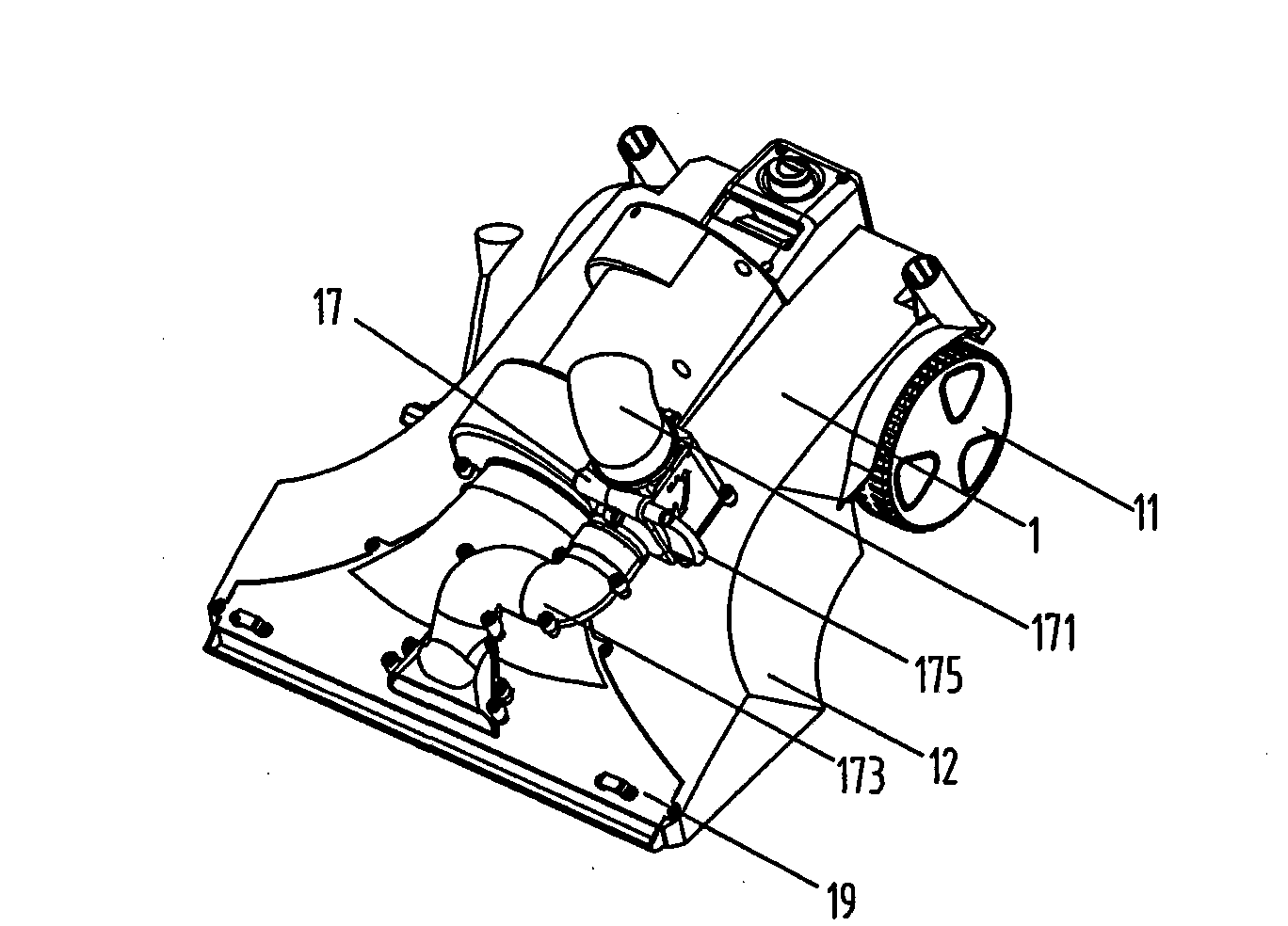

[0016] Figure 1 to Figure 6 As shown, the present invention creates a specific embodiment of a leaf blower, which includes a body assembly 1, a leaf collecting box 2, and a push rod 3, and the leaf collecting box 2 is arranged on the top of the body assembly 1, and the push rod 3 Fixedly connected with the body assembly 1, the body assembly 1 includes a casing 12, a motor 16, fan blades 42, a motor upper cover 43, front and rear wheels 144, 11, and the front and rear wheels 144, 11 are rotatably arranged on the casing 12 Above, motor 16 and fan blade 42 are installed on the casing 12 and are covered with motor loam cake 43, and motor 16 drives fan blade 42 to rotate during work, and the front portion of casing 12 is provided with front wind cover 19, for conveniently sucking up leaves, The air suction port of front wind cover 19 is towards the ground, and the leaf outlet 44 of front wind cover 19 links to each other with the air inlet of wind blade 42, and the air outlet 40 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com