Mounting structure of improved glass door

A technology for installing structure and glass door, applied in the installation of window glass, door/window accessories, building structure, etc., can solve the problem of easy tilting to the other side, and achieve the effect of ensuring levelness and uniform load distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

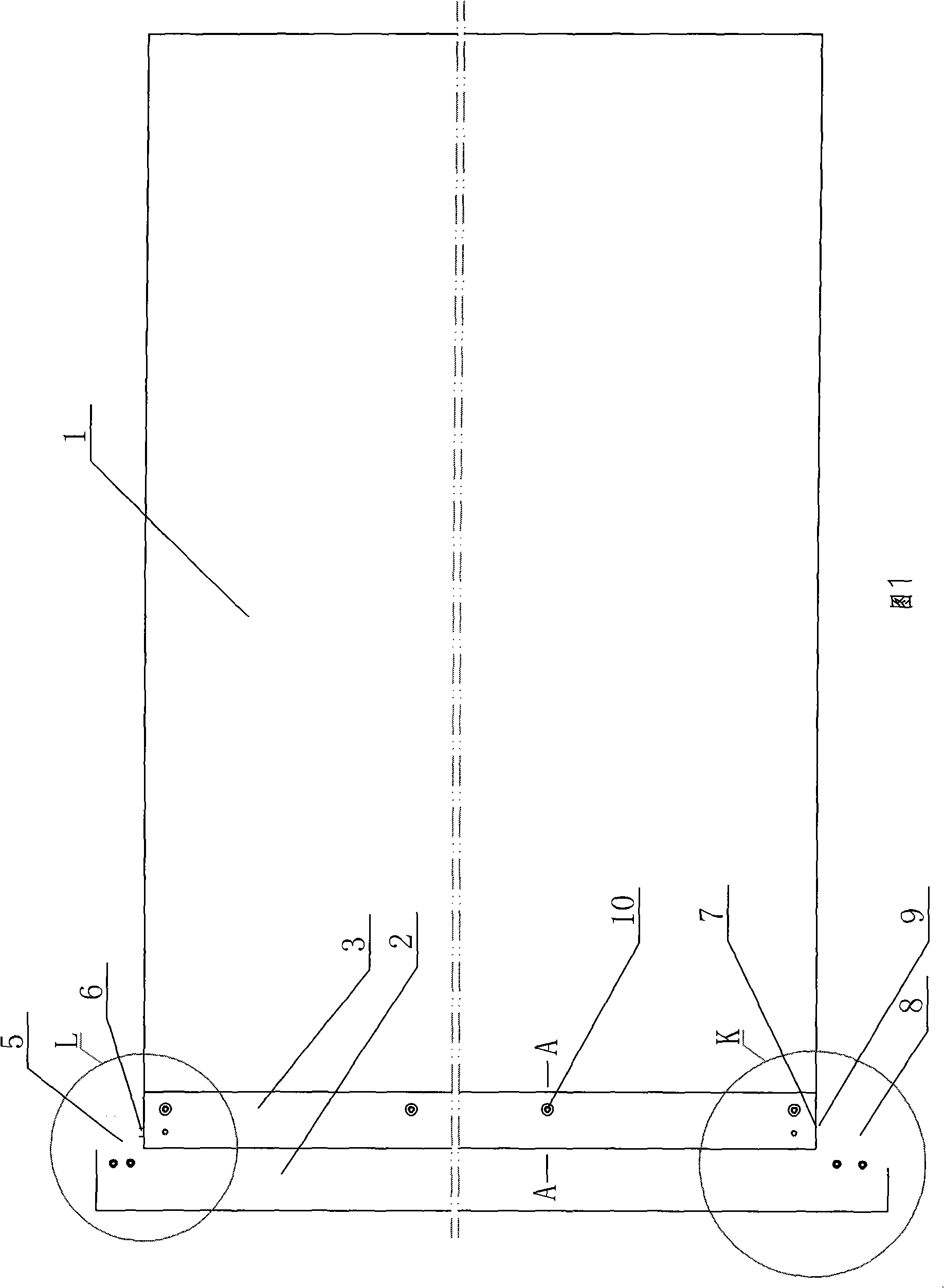

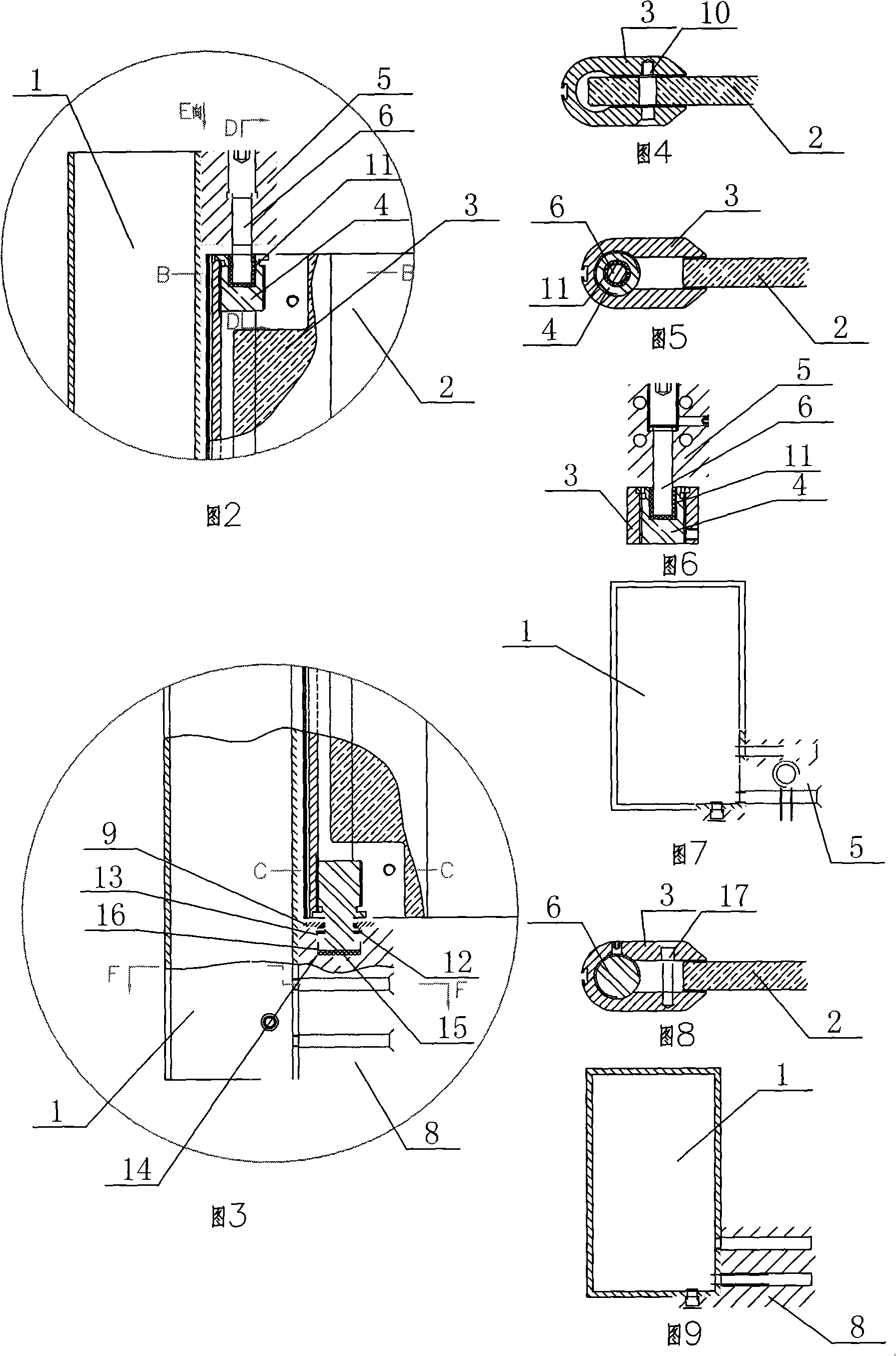

[0016] See Fig. 1, Fig. 2, Fig. 3, Fig. 4, Fig. 5, Fig. 6, Fig. 7, Fig. 8, and Fig. 9, which include a glass door 1, a door frame 2, and a side door clip 3 wrapping one side of the glass door 1 through the long side, Screws 10 connect both sides of the full-length side door clip 3 and one side of the glass door 1 clamped in the middle, the top of the full-length side door clip 3 is nested with a door clip top shaft seat 4, and the upper support seat 5 is connected to the door frame 2. The support seat 5 is located directly above the top shaft seat 4 of the door clip, and the upper fixed shaft 6 connects the upper support seat 5 and the top shaft seat 4 of the door clip. Connect the door frame 2, the lower support seat 8 is located directly below the bottom shaft 7 of the door clip, and the bottom shaft 7 of the door clip is connected to the lower support seat 8 through the sealing cover 9 sleeved on its end. The upper and lower ends of the long side door clamp 3 are connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com