Centering unit

A wafer and clamping cylinder technology, which is applied in the manufacture of electrical components, semiconductor/solid-state devices, circuits, etc., can solve problems such as wafer centering failure, wafer collision fragments, etc., and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

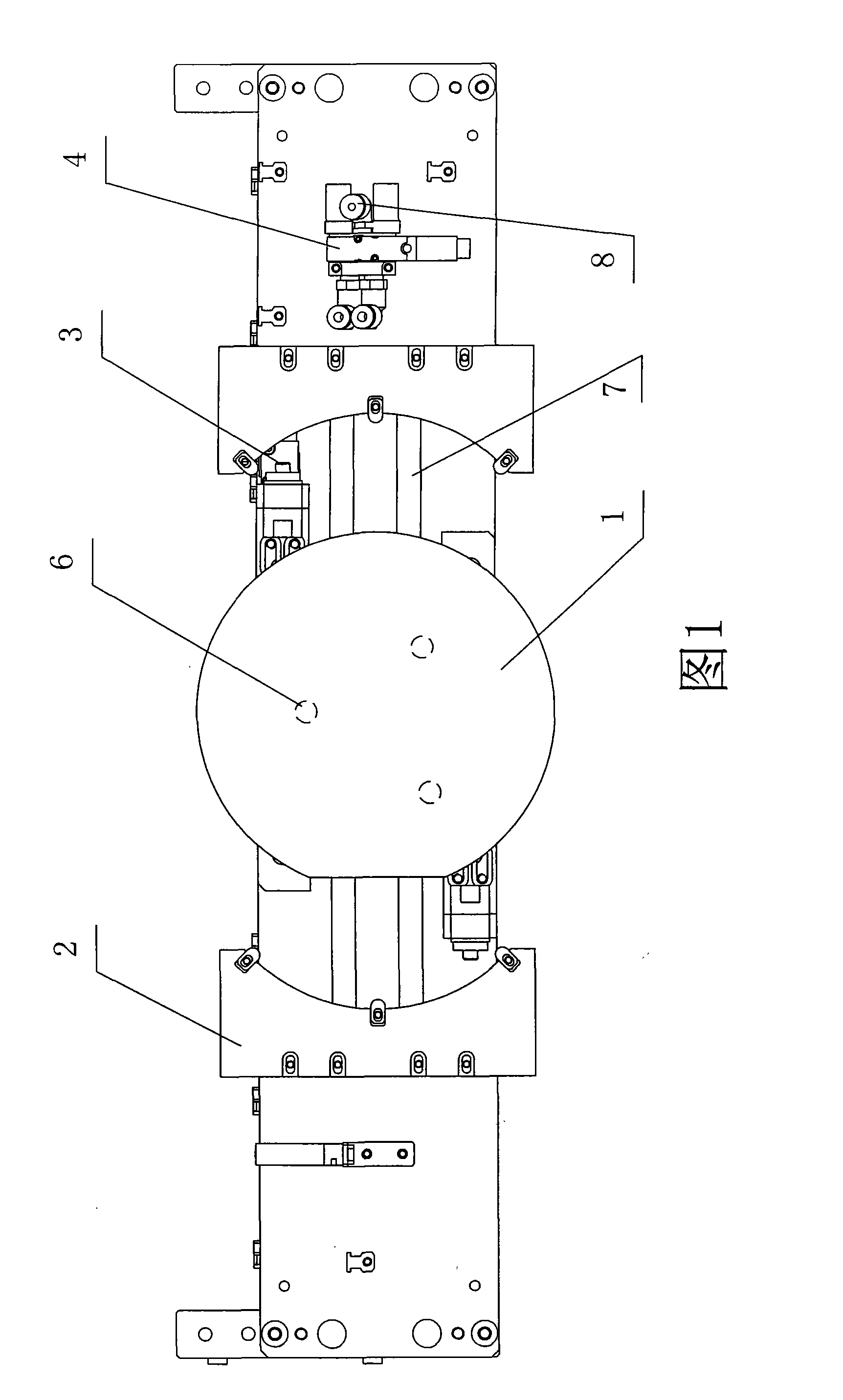

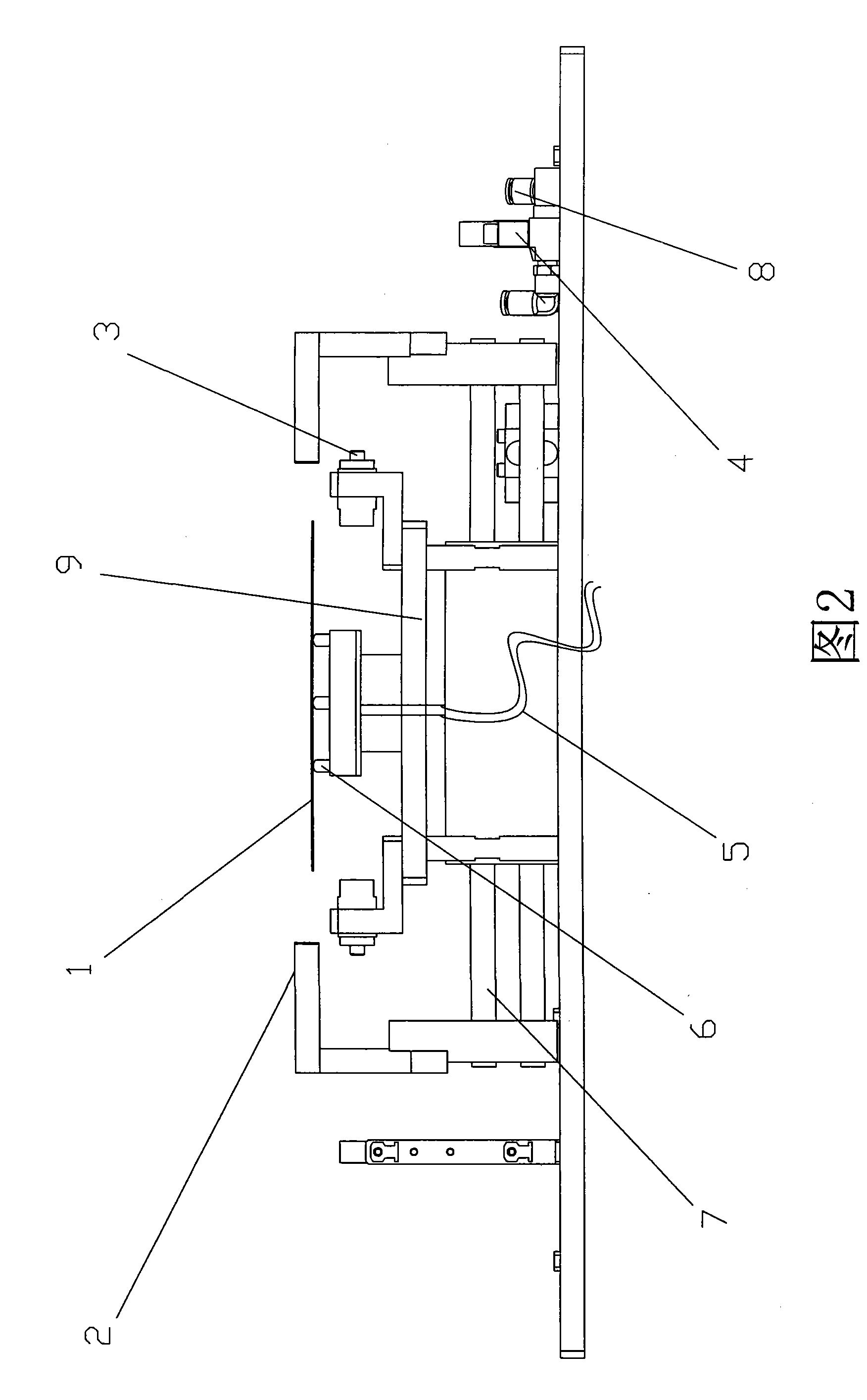

[0015] As shown in Fig. 1-2, the present invention is equipped with wafer centering part 2, clamping cylinder limiter 3, vacuum switch valve body 4, vacuum pipeline 5, wafer supporting pillar 6, clamping cylinder 7, clamping Cylinder on-off valve body 8, etc., are provided with three wafer supporting pillars 6 on the bracket 9 carrying the processed wafer 1, and the inside of the wafer supporting pillar 6 is made into a vacuum channel, and the vacuum channel in the wafer supporting pillar 6 passes through The vacuum pipeline 5 is connected to the vacuum switch valve body 4, and the two sides of the wafer supporting pillar 6 are provided with clamping cylinders 7, and the clamping cylinder 7 is controlled on and off by the clamping cylinder on-off valve body 8 connected thereto. The wafer centering part 2 corresponding to the outer edge of the processed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com