Improved type reinforced leadscrew type heavy-load four-jaw independent chuck

An improved and force-increasing technology, which is applied in the direction of the chuck, can solve problems such as insufficient clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

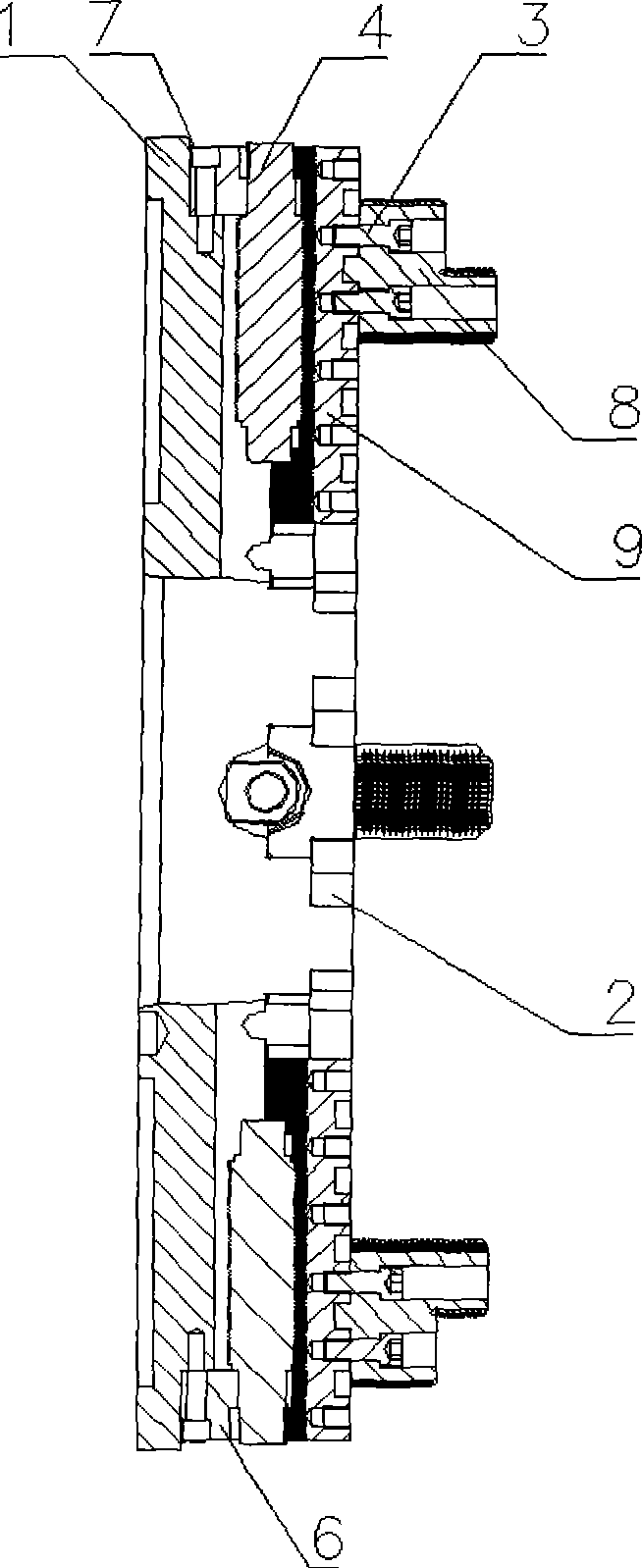

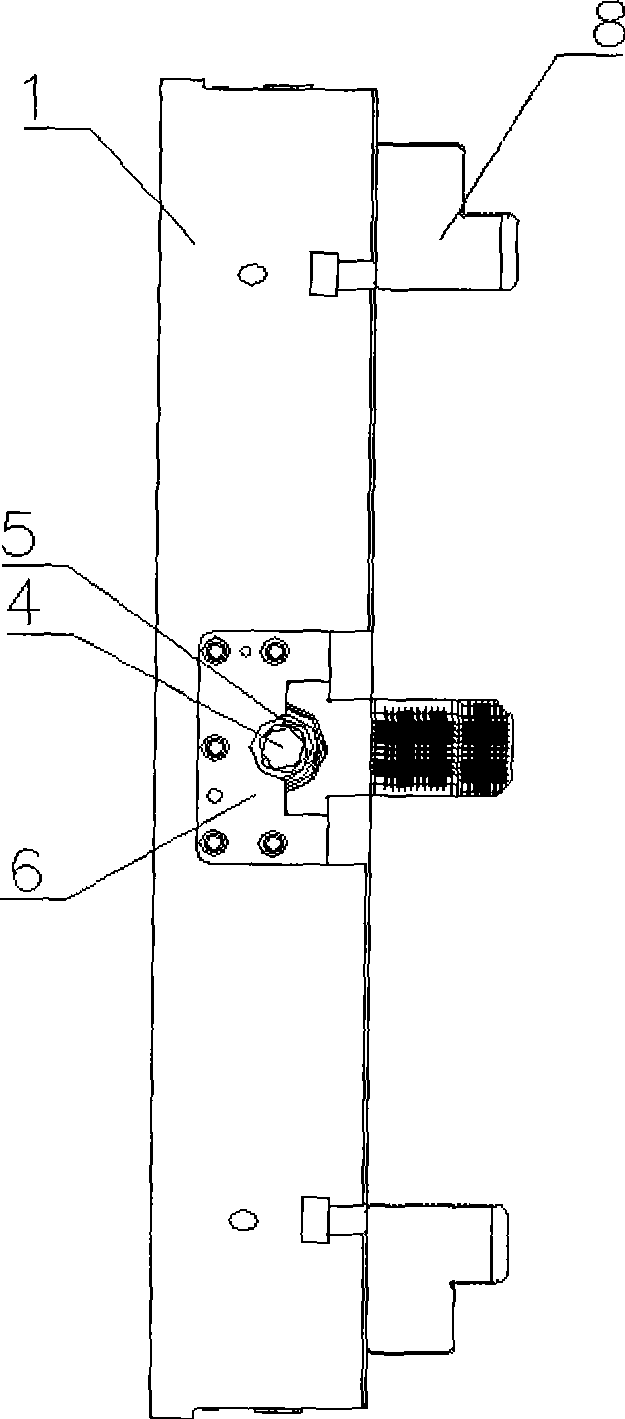

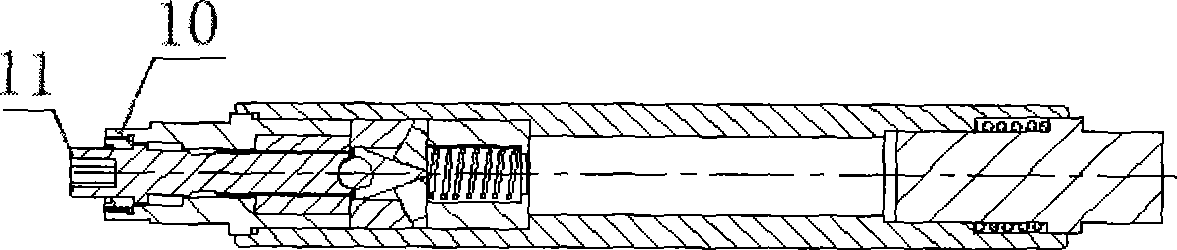

[0011] See figure 1 , figure 2 , the present invention comprises disc body 1, briquetting block 2, four claws 3, screw mandrel, and briquetting block 2 is positioned at the center of the upper surface of disc body 1, and four claws 3 are installed on disc body 1, and screw mandrel is for increasing The power screw 4 and the lower parts of the four claws 3 are respectively connected to the corresponding booster screw 4 , and the booster screw 4 is supported on the disc body 1 . The booster screw 4 is installed in the blind hole 5, and the blind holes 5 are evenly distributed on the circumferential surface of the disc body 1. The main shaft end of the booster screw 4 is connected with the plane thread of the disc body 1. The rod mounting block 6 and the screw mounting block 6 are installed in the screw mounting groove 7, the screw mounting grooves 7 are evenly distributed on the circumferential surface of the disk body 1, and the corresponding screw rod mounting grooves 7 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com