Fixed-length cutter mounting device of numerical control milling machine

A CNC milling machine and fixed-length technology, which is applied in the field of clamping instruments, can solve problems such as unstable clamping and inconvenient adjustment methods, achieve good clamping stability and safety, improve use safety and stability, and improve The effect of operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following are specific embodiments of the present invention, and further describe the technical solution of the present invention in conjunction with the accompanying drawings, but the present invention is not limited to these embodiments.

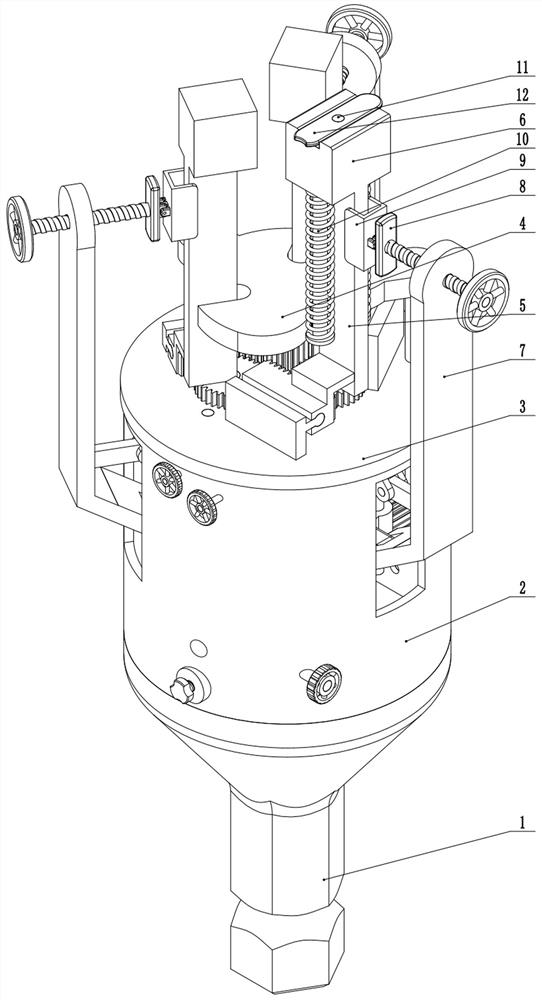

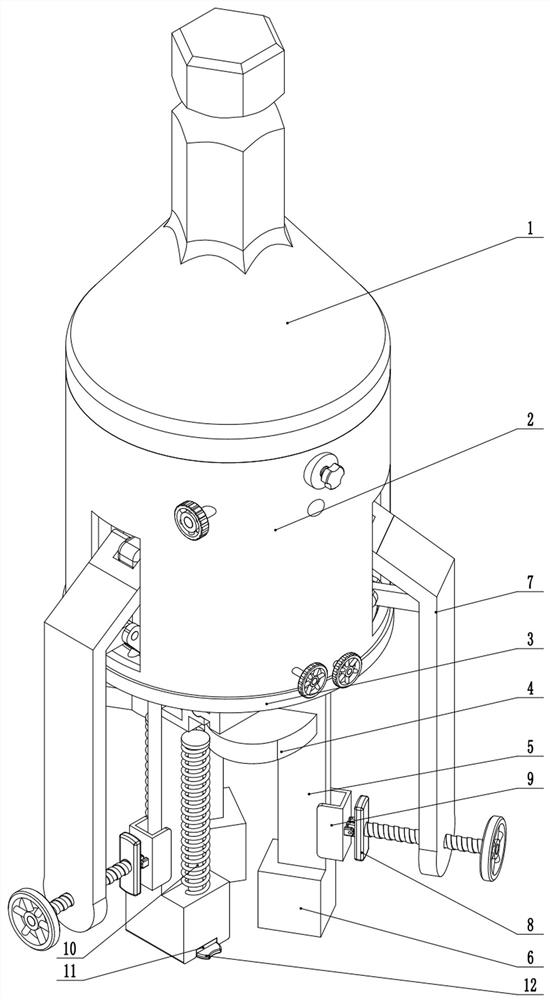

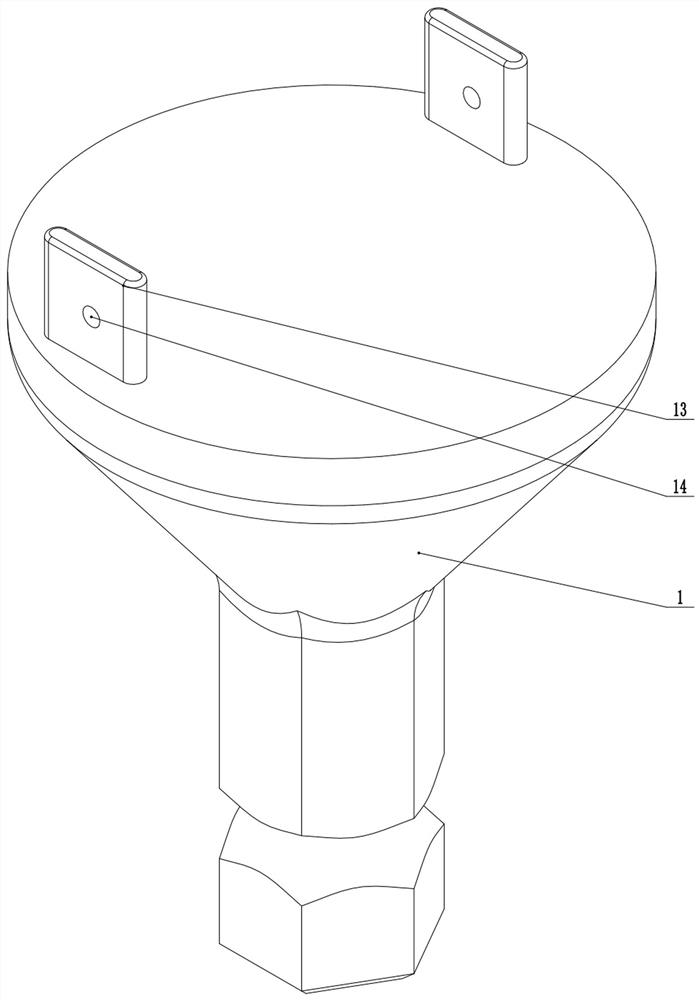

[0034] Such as Figure 1-11 As shown, the present invention provides a fixed-length tooling device for a CNC milling machine, including a connector 1, a detachable mounting cylinder 2 at the tail end of the connector 1, a mounting plate 3 fixed at the tail end of the mounting cylinder 2, and a mounting plate 3 at the tail end. There are a plurality of radially movable clamping arms 5, clamping blocks 6 are respectively arranged at the tail ends of the clamping arms 5, and an ejector plate 4 with an adjustable vertical position is provided at the center of the tail end of the mounting plate 3. The outer circumference of the cylinder 2 is provided with a plurality of radially swingable reinforcing arms 7, and the side of the tail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com