Novel cathode structure of aluminum cell

A cathode structure, aluminum electrolytic cell technology, applied in the field of aluminum electrolytic cell structure and current supply device, can solve the problems of uneconomical, huge electric power of auxiliary power supply, etc., achieve the effect of saving consumption, simple configuration, and ensuring stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

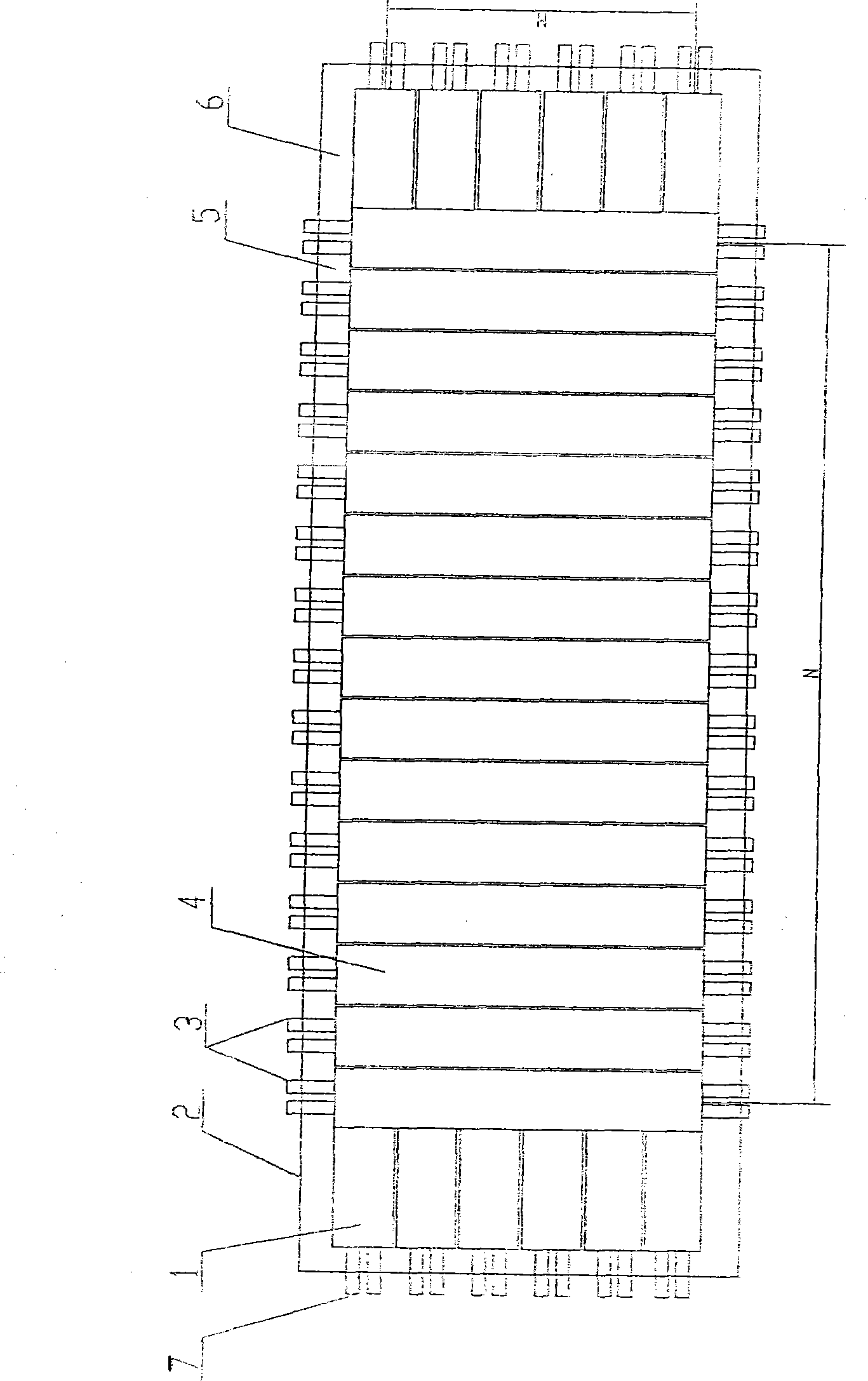

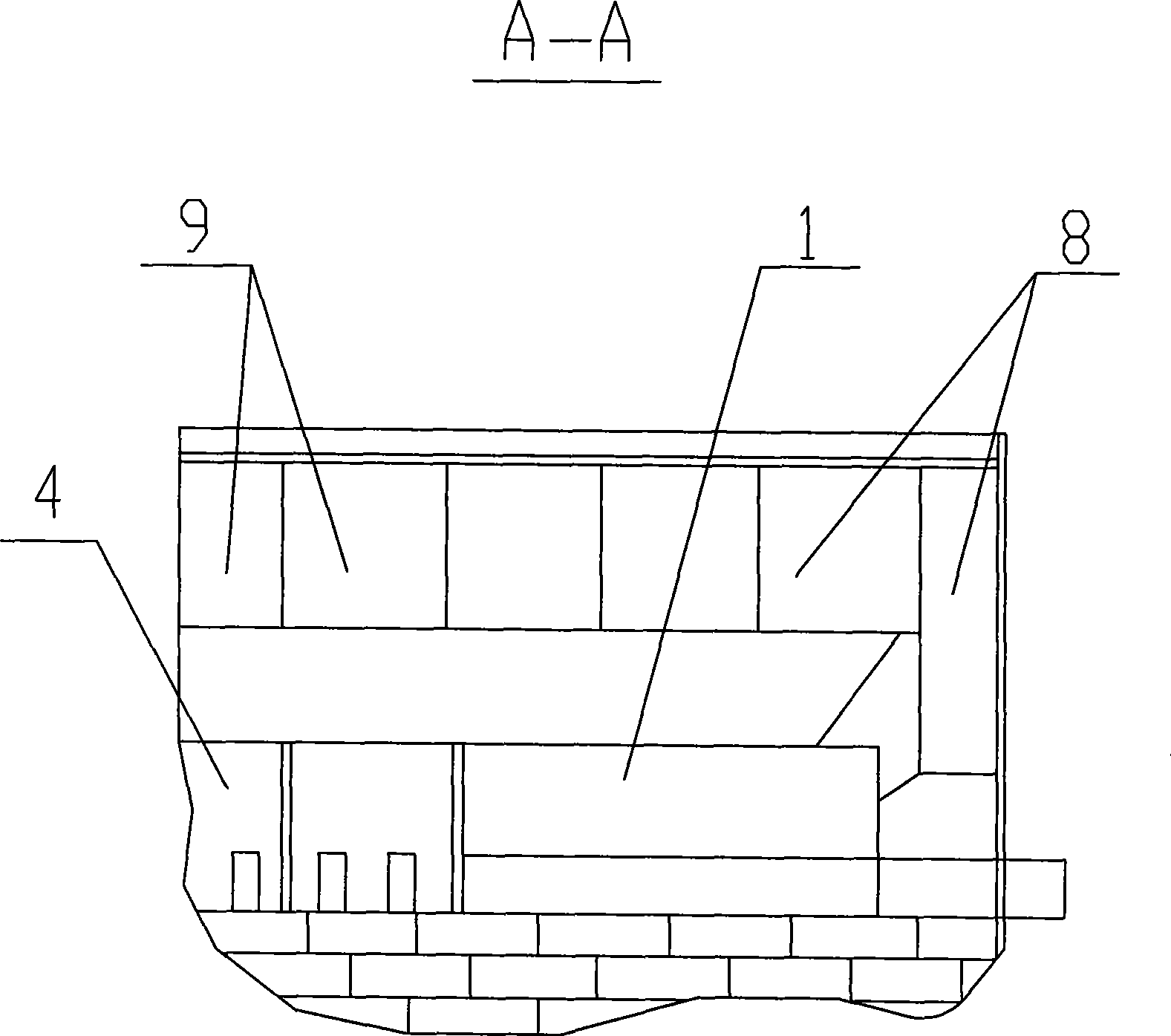

[0016] Example 1 The cathode structure of a 300KA aluminum electrolytic cell

[0017] For the 300KA aluminum electrolytic cell, the length of the long cathode carbon block is 3200-3850 mm, and the width is 450-700 mm; the length of the short cathode carbon block is 1200-1800 mm, and the width is 450-700 mm. The number (M) of short cathode carbon blocks in the whole electrolyzer is 4 to 6 groups; the number (N) of long cathode carbon blocks is 24 to 30 groups.

Embodiment 2

[0018] Example 2 Cathode structure of 360KA aluminum electrolytic cell

[0019] For the 360KA aluminum electrolytic cell, the length of the long cathode carbon block is 3200-3850 mm, and the width is 450-700 mm; the length of the short cathode carbon block is 1200-1800 mm, and the width is 450-700 mm. The number (M) of short cathode carbon blocks in the whole electrolyzer is 4 to 6 groups; the number (N) of long cathode carbon blocks is 24 to 30 groups.

Embodiment 3

[0020] Example 3 Cathode structure of 400KA aluminum electrolytic cell

[0021] For the 400KA aluminum electrolytic cell, the length of the long cathode carbon block is 3200-3850 mm, and the width is 450-700 mm; the length of the short cathode carbon block is 1200-1800 mm, and the width is 450-700 mm. The number (M) of short cathode carbon blocks in the whole electrolyzer is 6-8 groups; the number (N) of long cathode carbon blocks is 24-32 groups.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap