Large-sized ultra-high pressure connecting flange structure

A connection flange, ultra-high pressure technology, applied in the direction of flange connection, pipe/pipe joint/pipe fitting, through components, etc., can solve the problem of large diameter and high pressure of connecting flange, large deformation of connecting flange, unable to use normally, etc. problem, to achieve good sealing effect, long life and reliable use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

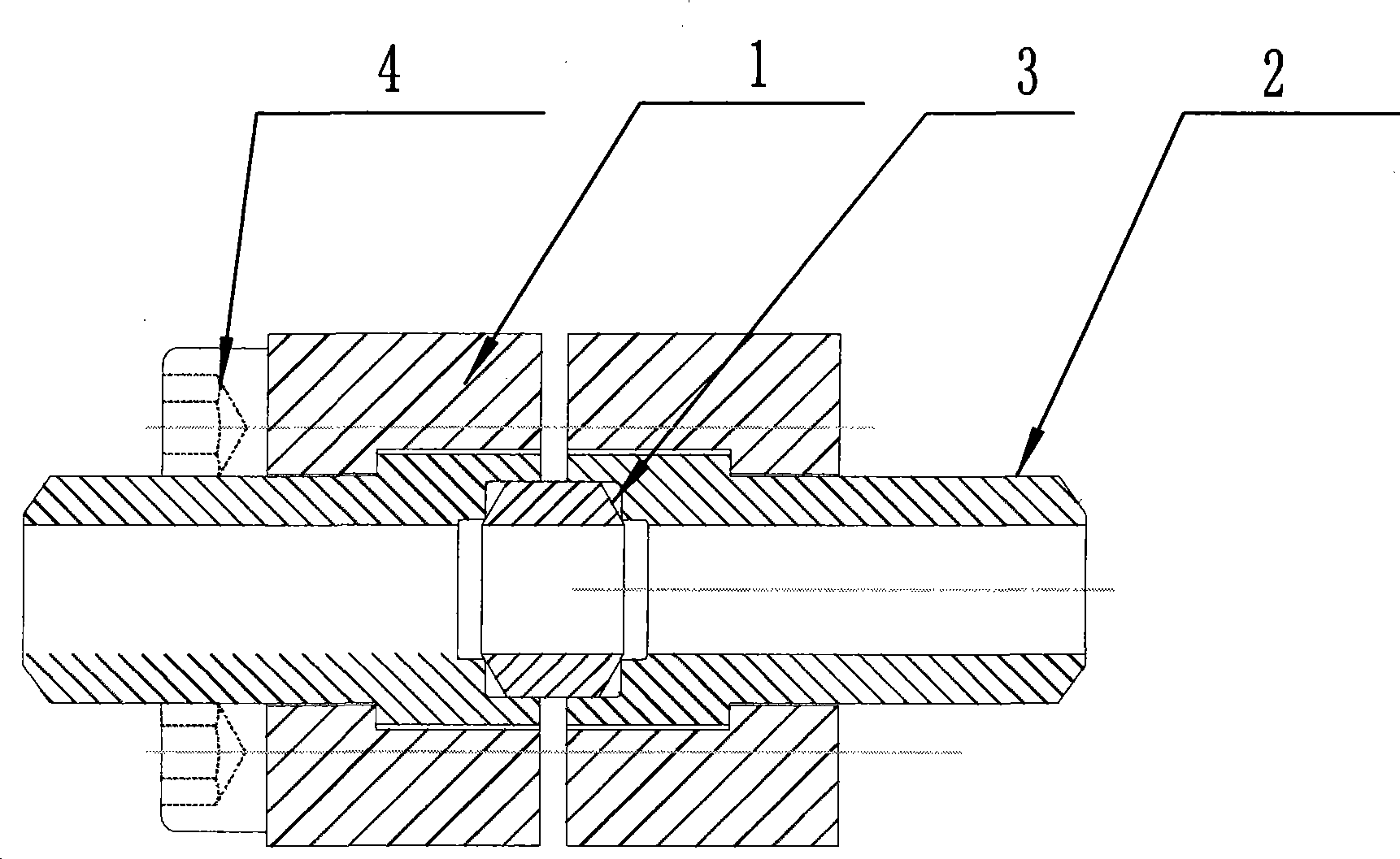

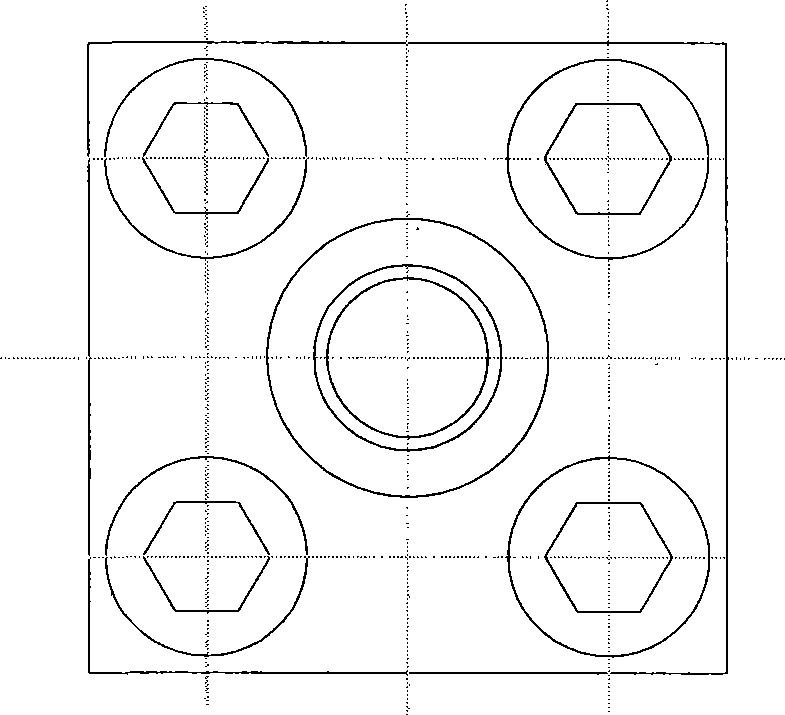

[0013] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a flange 1 and a joint body 2. The sealing edge of the joint body 2 is pressed against the flange 1 with a metal taper 3, and the flange 1 is equipped with a connecting screw 4; the metal taper 3 is bidirectional. tapered surface.

[0014] As shown in the figure: the metal cone gasket 3 is designed as a two-way cone surface, and the sealing edge of the cone surface and the joint body 2 is pressed against the flange plate 1, and the metal seal can be realized by continuously tightening the connecting screw 4. When oil leakage occurs, the oil leakage phenomenon can be eliminated by tightening the connecting screw 4 again.

[0015] This product connects the flange plate 1 by the connecting screw 4, and it is enough to press the joint body 2 and the metal cone washer 3. In particular, the coaxiality between the metal cone washer 3 and the joint body 2 must be strictly r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap