Automated warehouse and method of supplying clean air to the automated warehouse

An automatic warehouse, clean air technology, applied in cleaning devices, lifting devices, conveyor objects, etc., can solve problems such as reducing storage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The best embodiment for carrying out the present invention is described below.

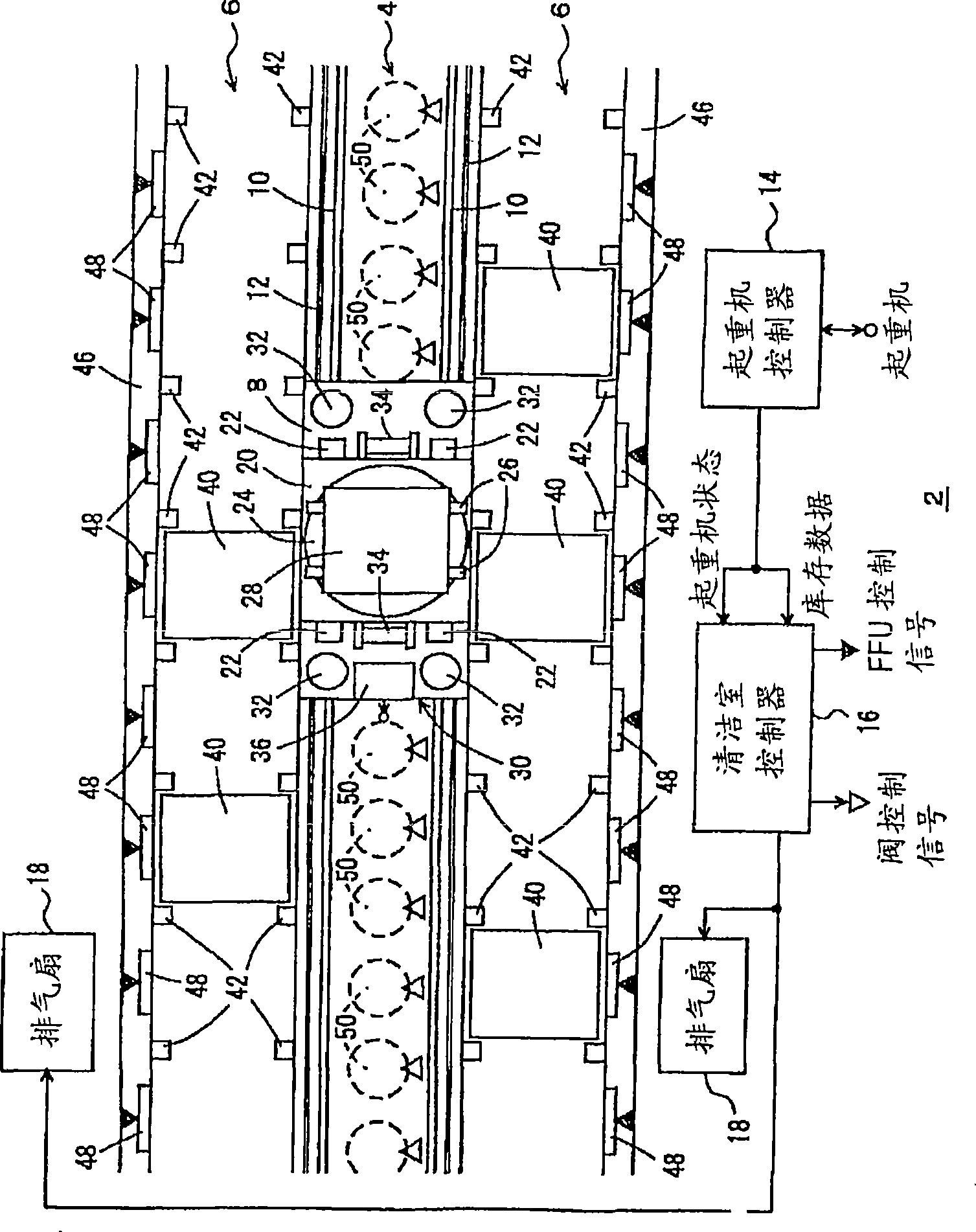

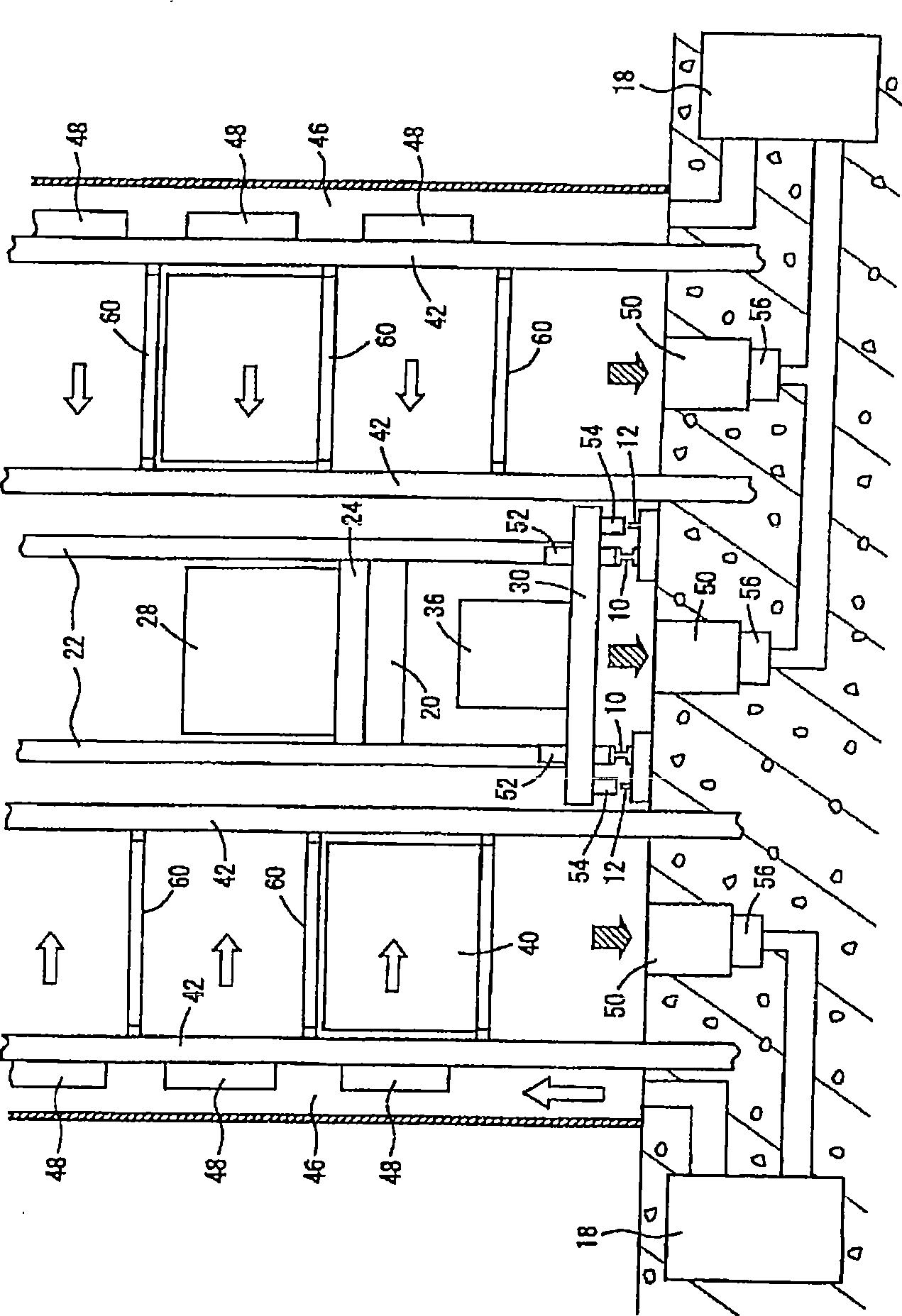

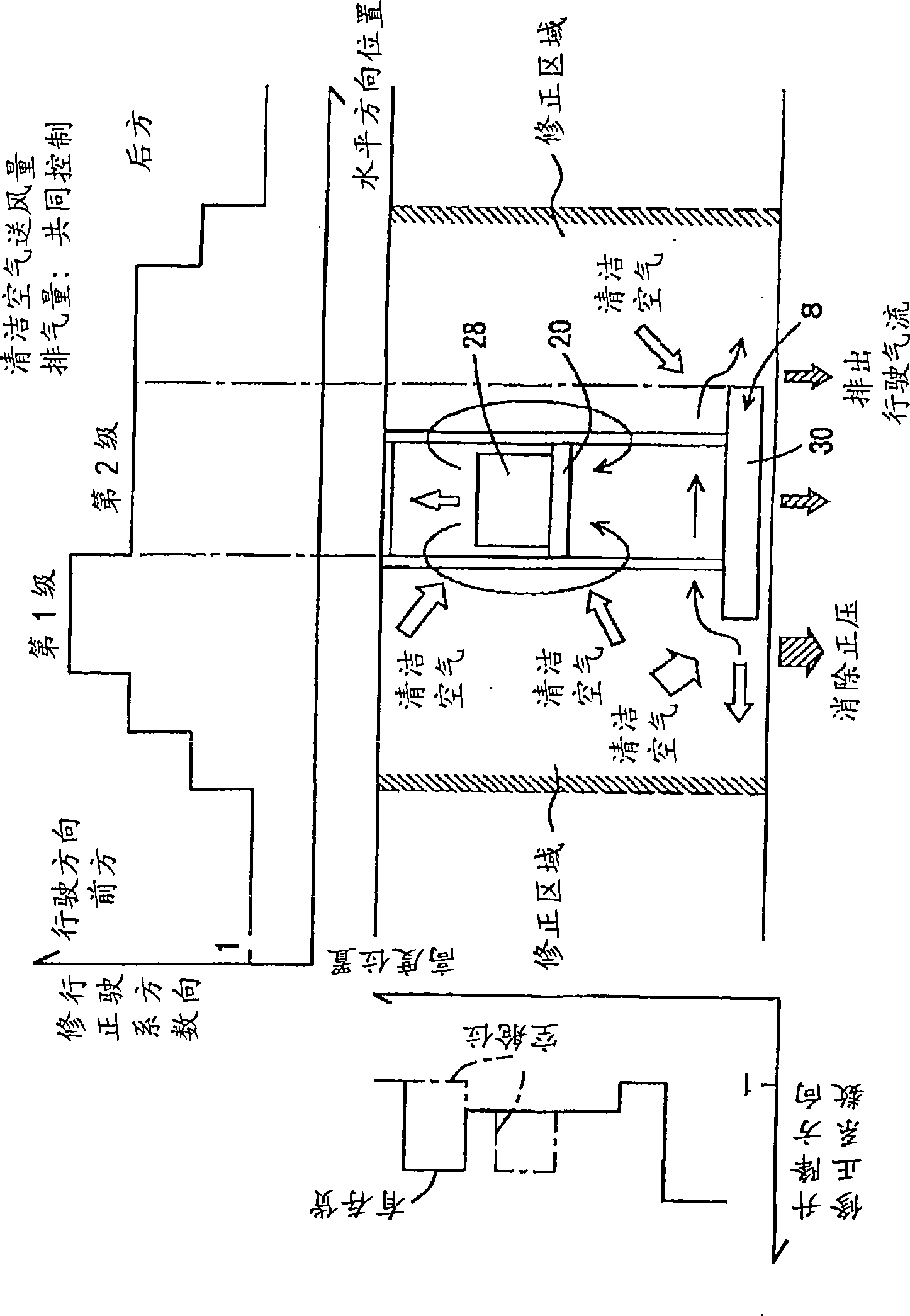

[0047] Figure 1 ~ Figure 4 The automatic warehouse 2 of an example is shown. In each figure, 4 represents a running space, and there are racks 6, 6 on its left and right sides. In addition, a part of the rack 6 may be used as a docking point for storage or egress, and processing devices such as liquid crystal substrates may be provided on the rear side of the rack 6 viewed from the travel space 4 side. The running space 4 is the access of the stacking crane 8, 10 is the running track, and 12 is the magnetic marker. Here, a pair of left and right running rails 10, 10 are used, but one rail 10 may be used. For example, a pair of magnetic markers 12 are arranged on the left and right parallel to the running rail 10 in order to enable the stacker crane 8 to always recognize its current position.

[0048] Instead of obtaining the absolute position by detecting the magnetic marker 12 , the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com