Double-interlock double-cone energizing pulling shank tensioning mechanism

A double-cone, double-interlocking technology, applied in the direction of the chuck, can solve the problem of loose tool handle fixation, and achieve the effect of increased safety performance and firm fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

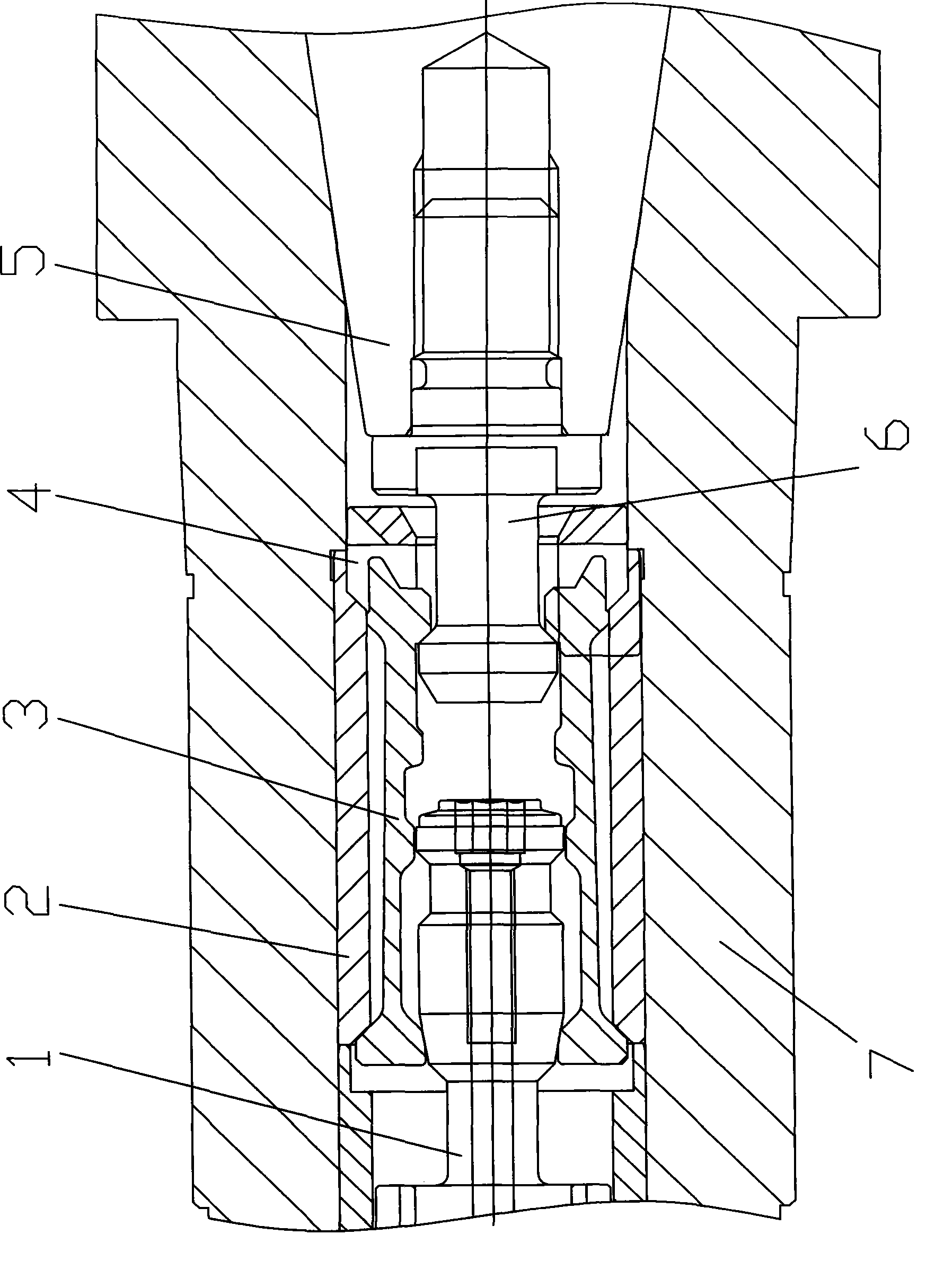

[0016] Such as figure 1 Shown: 7 main shafts, 5 is that the taper surface fits between tool handle and main shaft 7. The handle of a knife 5 is screwed and fastened to the right end of the pull stud 6 . The pull stud 6 is processed with a pull stud tapered surface 11 .

[0017] Such as figure 1 , shown in 5,6: be fixed with unlocking frame 2 at the endoporus place of main same 7, the left end inboard of unlocking frame 2 is processed with unlocking frame cone 13, and the right-hand end is processed with four openings 12 that are evenly distributed on the circumference.

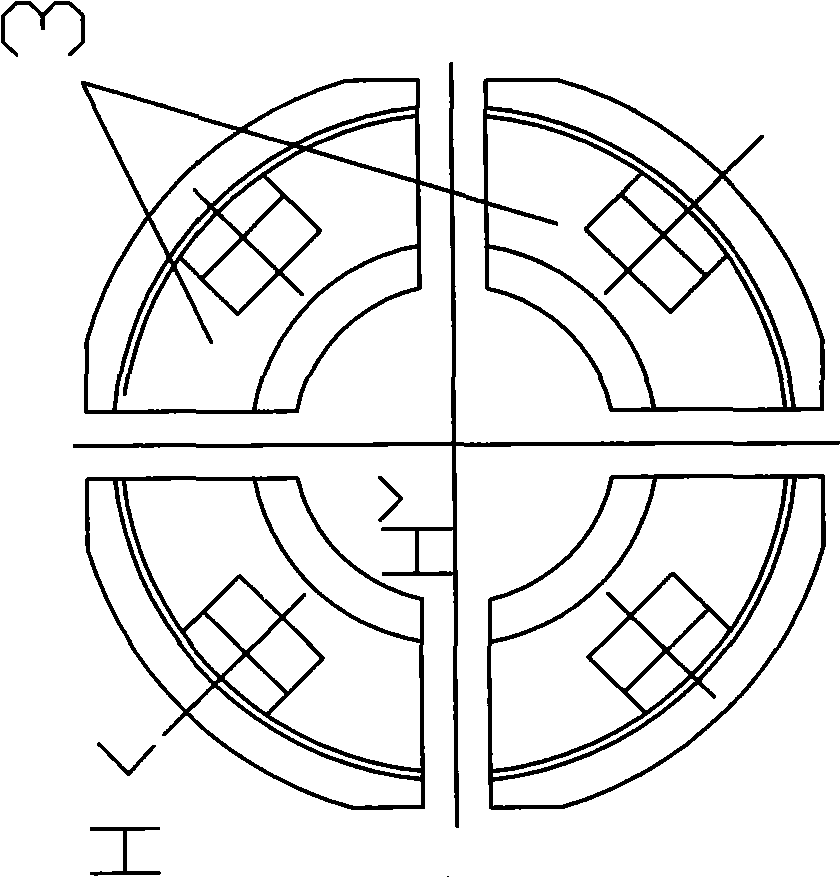

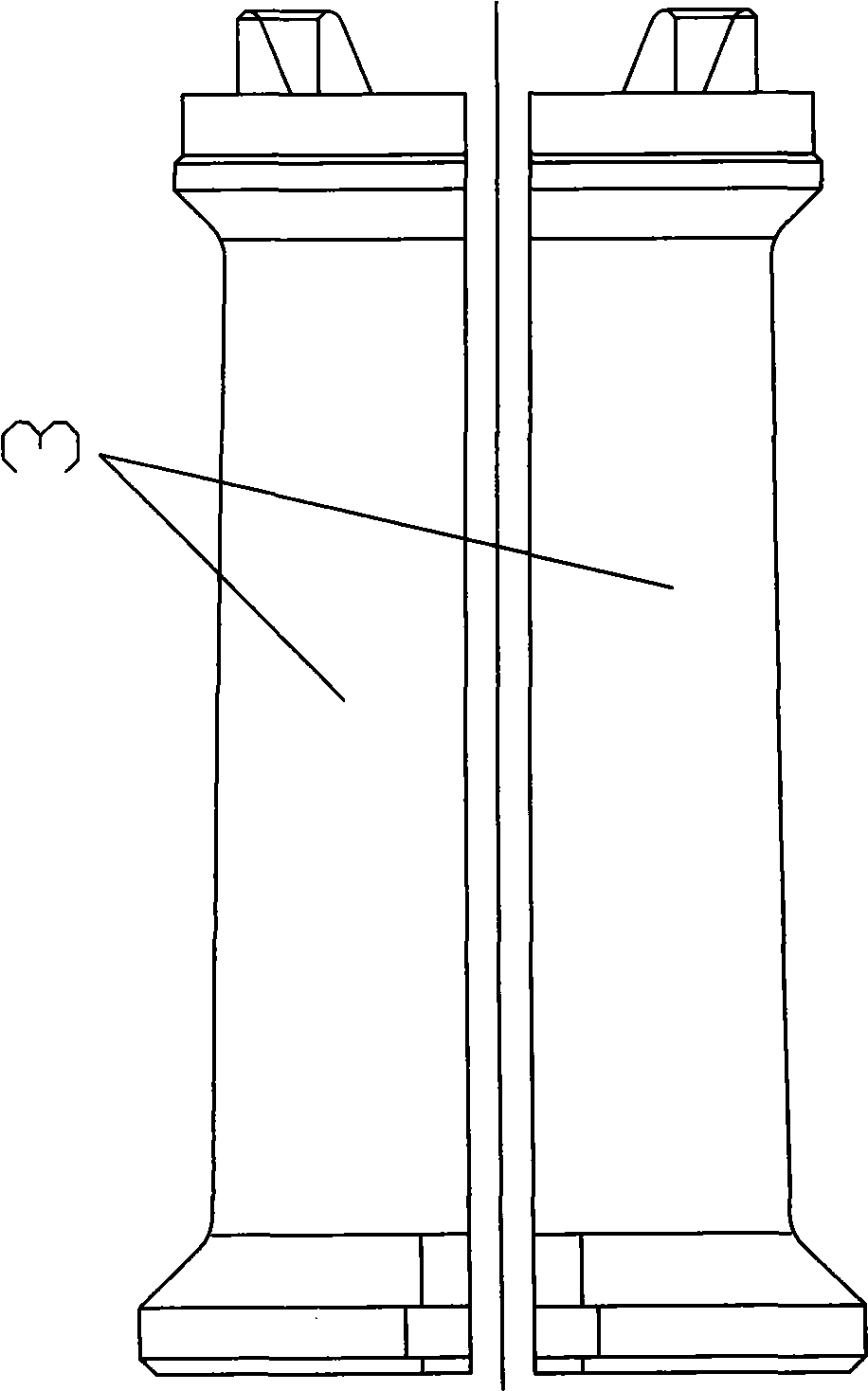

[0018] Such as figure 1 , 2 , Shown in 3, 4, and 6: the inboard of unlocking frame 2 is provided with clamping valve 3, and clamping valve 3 is four, is evenly distributed on the circumference. During processing, the cylindrical whole is processed first, and then cut into four equal parts. Its left end inboard is processed with inner cone 9, and the outside is processed with outer cone 8, and outer cone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com