Labor-saving bolt cutter

A technology of bolt cutters and pliers body, applied in the field of hand tools, can solve the problems of large volume, heavy weight, limited space for use, etc., and achieve the effect of small size and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

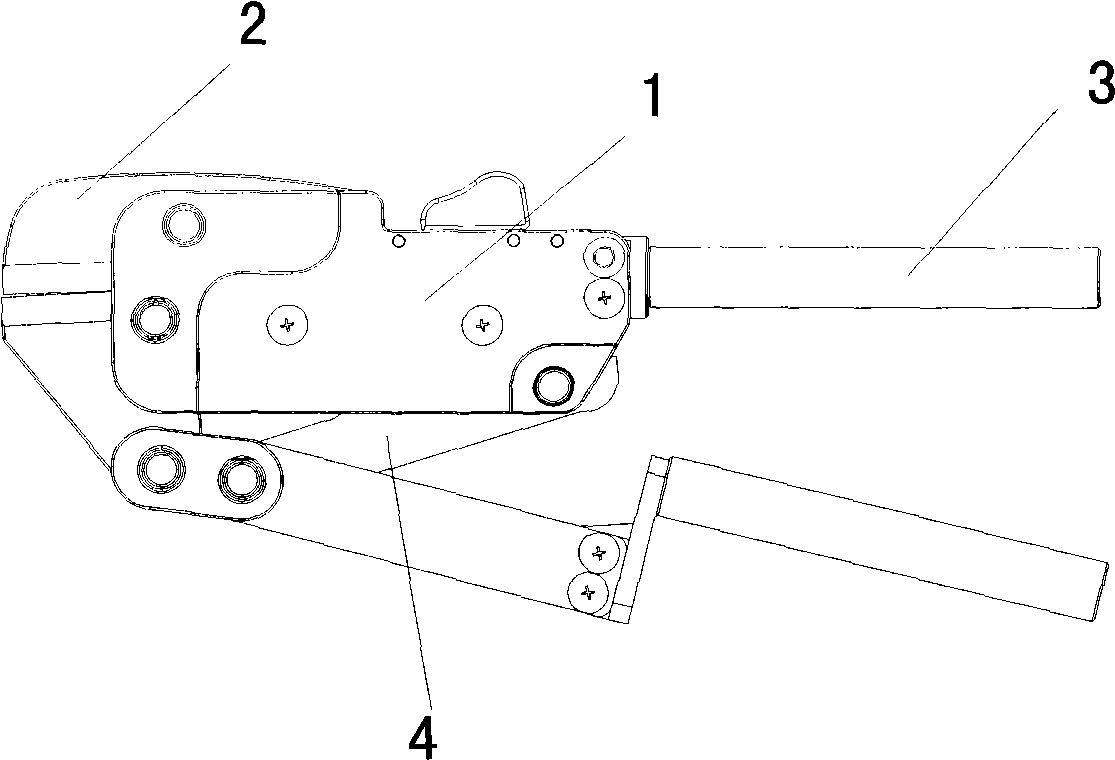

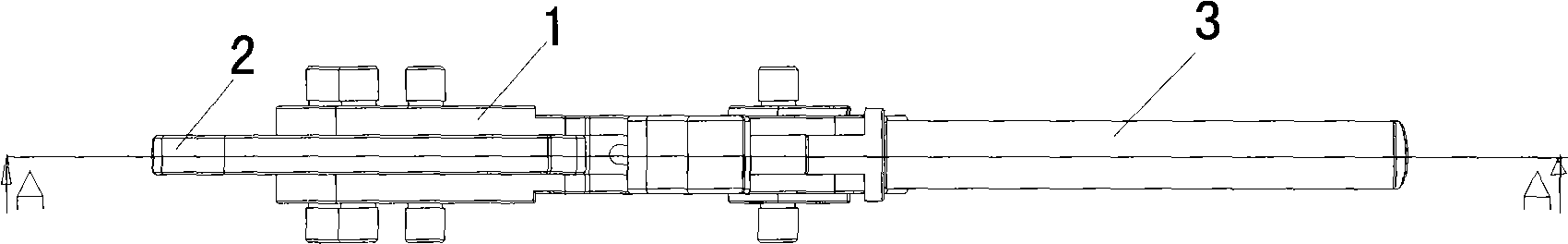

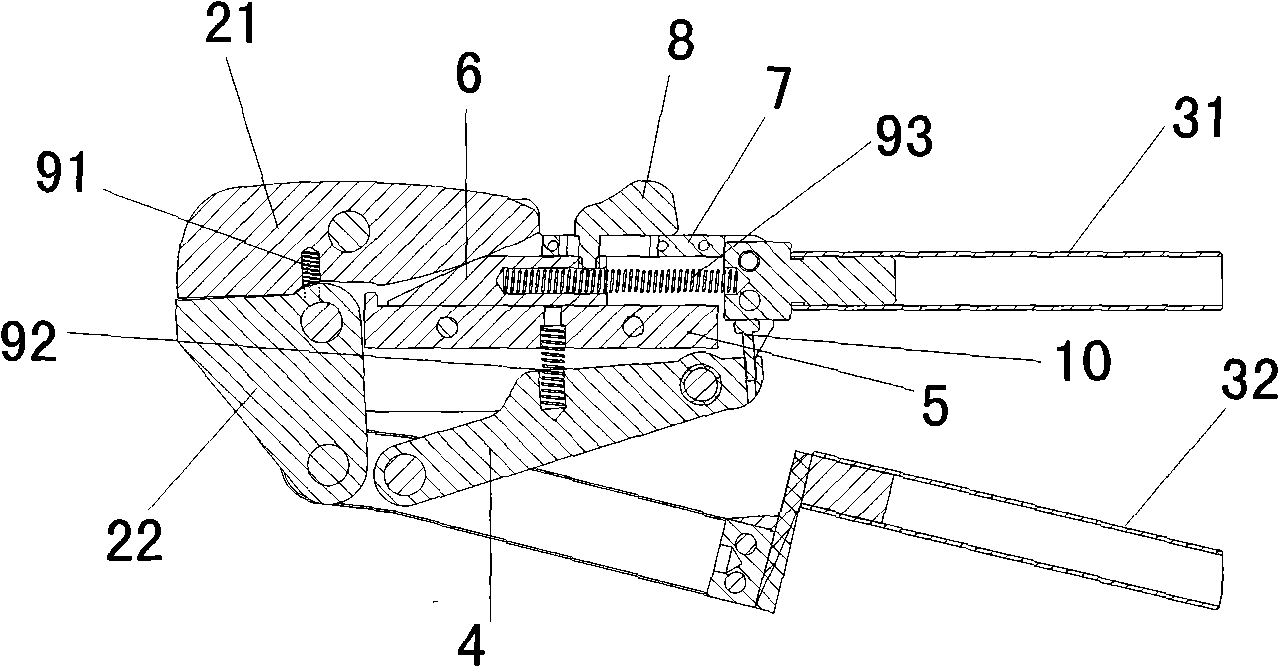

[0027] see figure 1 , refer to figure 2 , image 3 , Figure 4 , Figure 5 , the labor-saving bolt cutter of the present invention comprises a pliers body 1 made up of a left pliers body 11 and a right pliers body 12, a jaw 2 made up of an upper jaw 21 and a lower jaw 22, an upper handle 31 and a lower handle 32 Handle 3, lever 4, guide rail 5, wedge block 6, guide groove 7, push button 8, tension spring 91, stage clip 92, return spring 93 and limit bolt 10 of composition.

[0028] The upper jaw 21 and the lower jaw 22 are all arranged between the left jaw body 11 and the right jaw body 12 and are rotatably connected with the left jaw body and the right jaw body respectively. The wedge of the wedge fits.

[0029] The upper handle 31 is composed of a fixed connector 311 and a movable handle tube 312 , the front end of the fixed connector 311 is fixedly connected with the pliers body 1 , and the rear end is connected with the movable handle tube 312 by socketing. Lower ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com