Die trimming method

A trimming and mold technology, applied in the direction of metal processing, etc., can solve the problems of complex operation, increased mold processing procedures, high cost, etc., and achieve the effect of reducing costs, reducing procedures, cutting and repairing labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

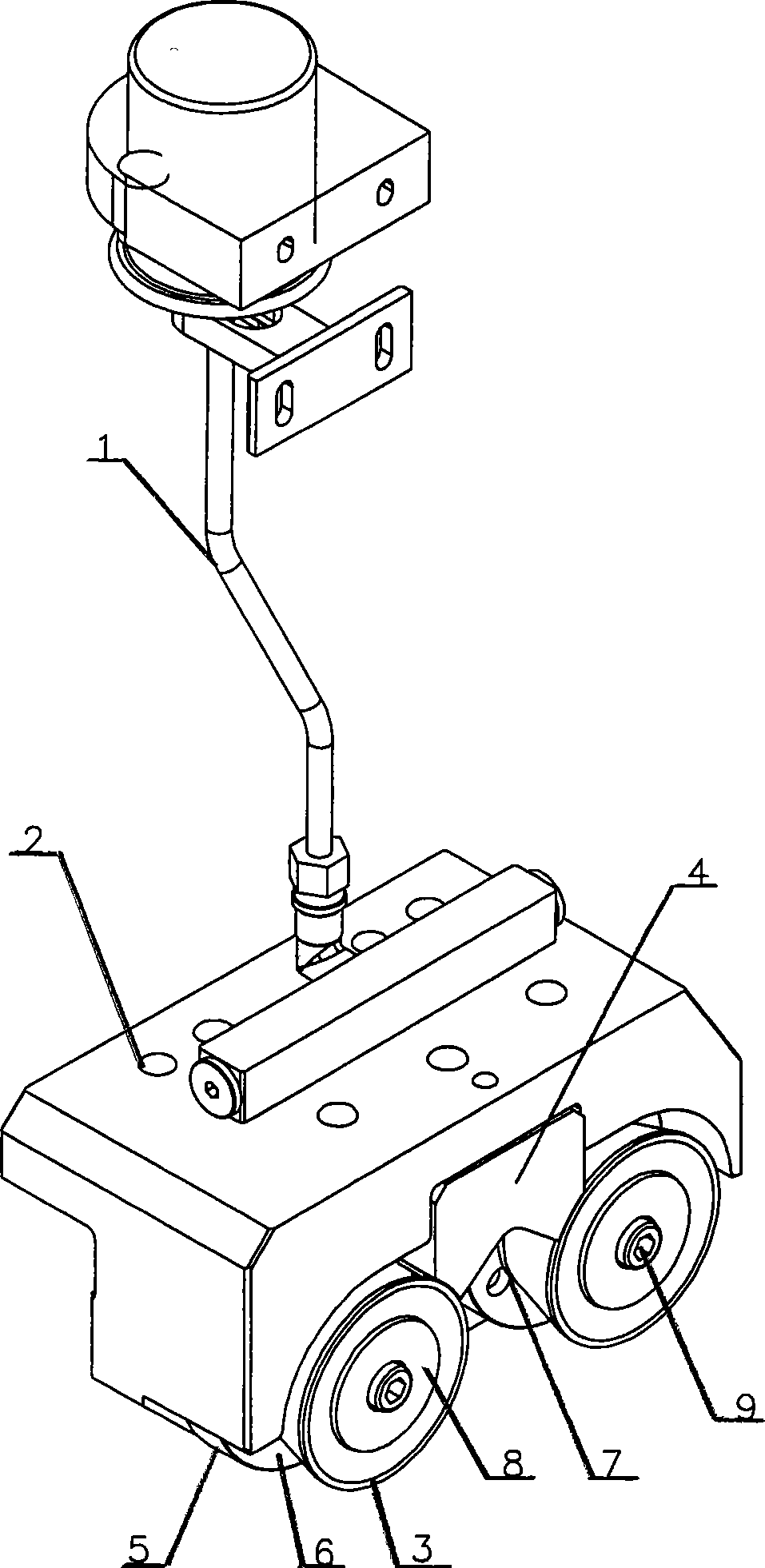

Image

Examples

Embodiment 1

[0015] First, fix the edge trimming mechanism on the upper mold of the mold, so that the cutting edge of the edge trimming mechanism faces the cutting edge of the workpiece, and the edge trimming mechanism moves downward with the upper mold, when the cutting edge of the edge trimming mechanism touches When trimming, the trimming mechanism continues to move downward with the drive of the upper die, and the fixed cutting edge cuts off the trimming edge of the workpiece. This method can complete the trimming of the horizontal edge.

Embodiment 2

[0017] First, fix the edge trimming mechanism on the upper mold of the mold, so that the cutting edge of the edge trimming mechanism faces the cutting edge of the workpiece, and the edge trimming mechanism moves downward with the upper mold, when the cutting edge of the edge trimming mechanism touches When trimming, the trimming mechanism continues to move downward with the drive of the upper die, and the rotating cutting blade on the side of the fixed cutting blade starts to rotate around the central axis to cooperate with the fixed cutting blade until the cutting edge of the workpiece is cut off. Straight side trimming can be done.

Embodiment 3

[0019] First, fix the edge trimming mechanism on the upper mold of the mold, so that the cutting edge of the edge trimming mechanism faces the cutting edge of the workpiece, and the edge trimming mechanism moves downward with the upper mold, when the cutting edge of the edge trimming mechanism touches When trimming, the trimming mechanism continues to move downward with the drive of the upper die, and the rotating cutting blades on both sides of the fixed cutting blade start to rotate around the central axis to cooperate with the fixed cutting blade until the trimming edge of the workpiece is cut off to complete the U-shape Edge trimming.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com