Trimming and punching die for rear connecting cross beam of panoramic sunroof

A technology of trimming punching die and connecting beams, which is applied in the direction of perforating tools, forming tools, peeling devices, etc., can solve the problems of needing to stop for cleaning, large labor cost investment, low processing efficiency, etc., to reduce costs and improve use. Longevity and effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

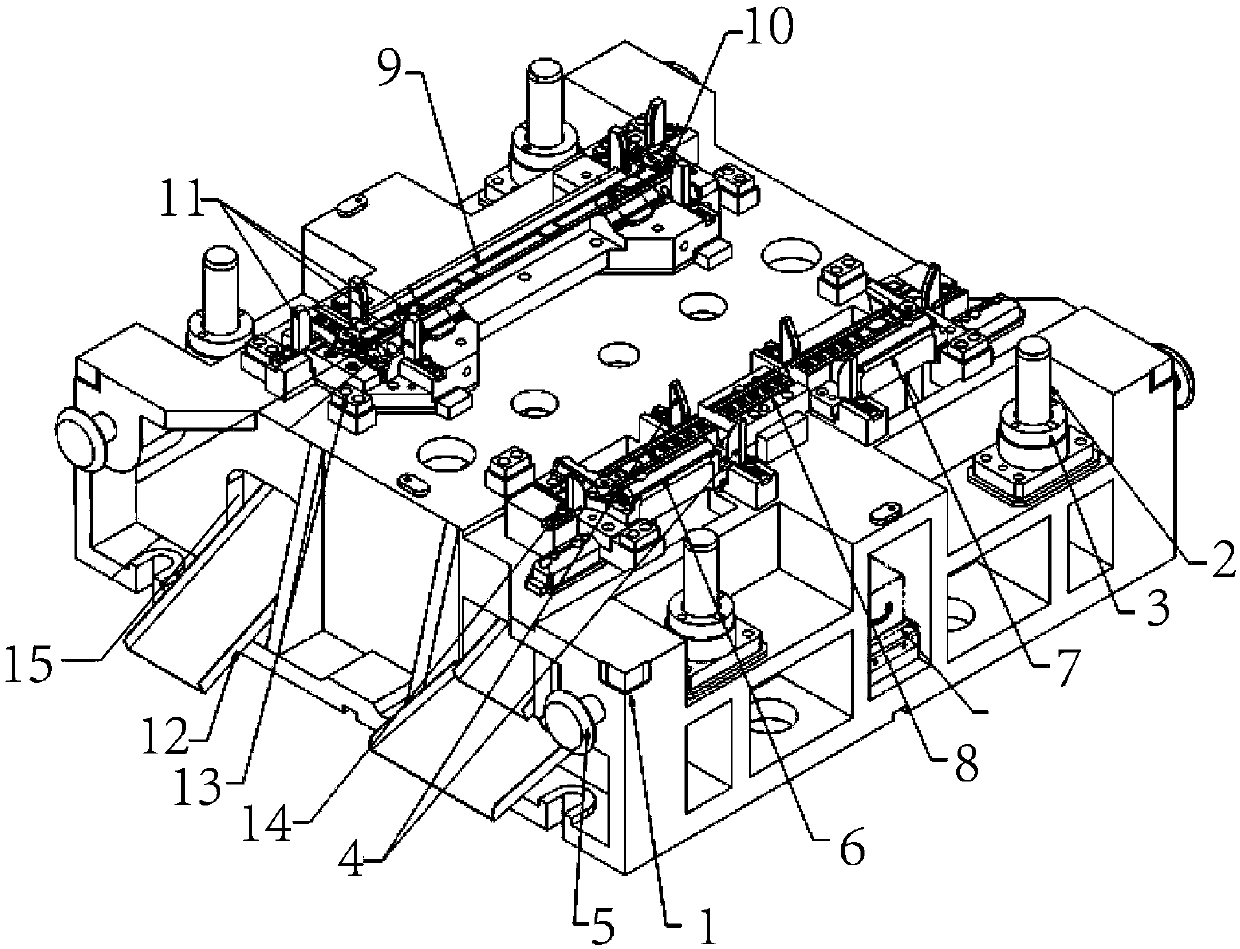

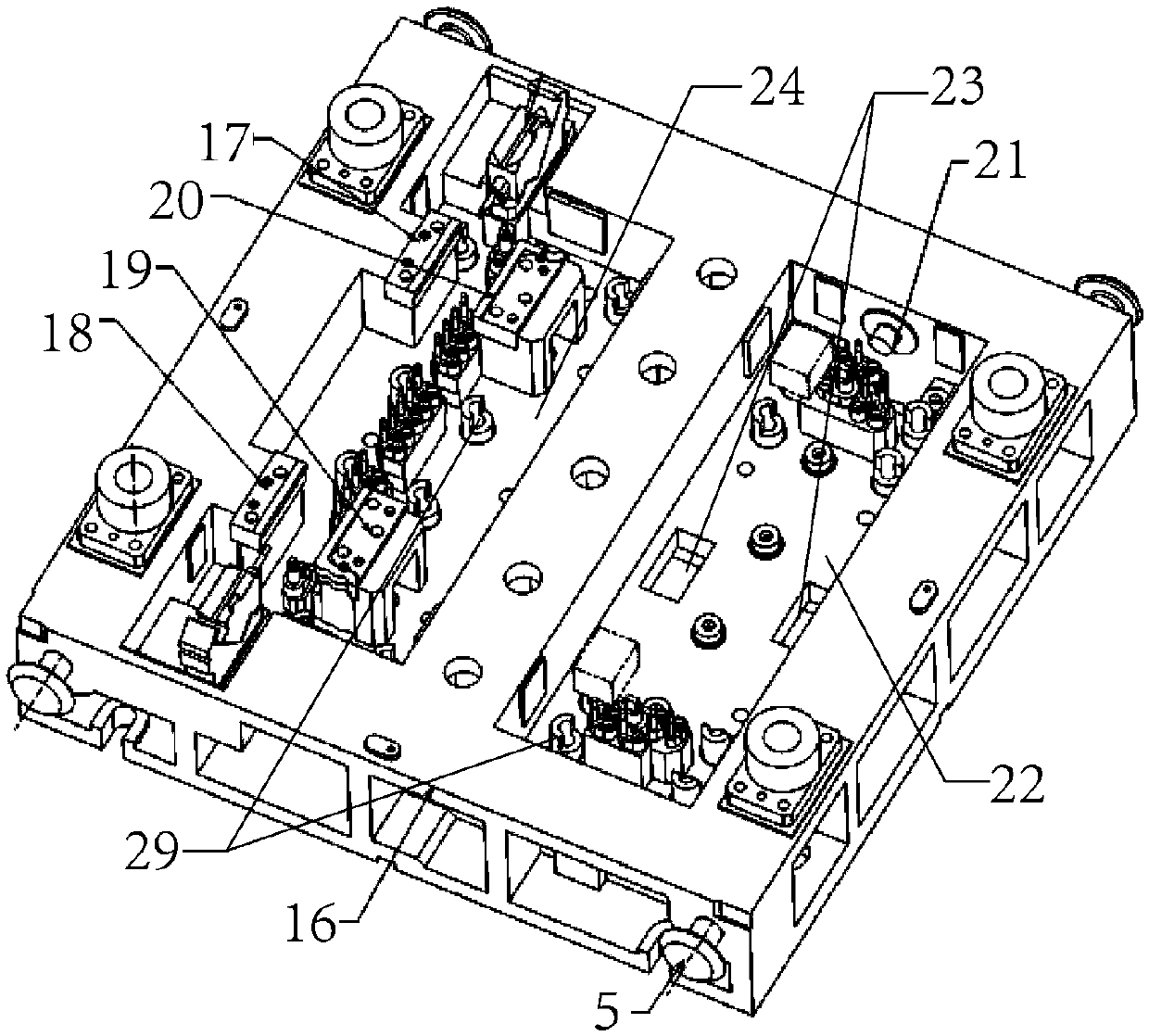

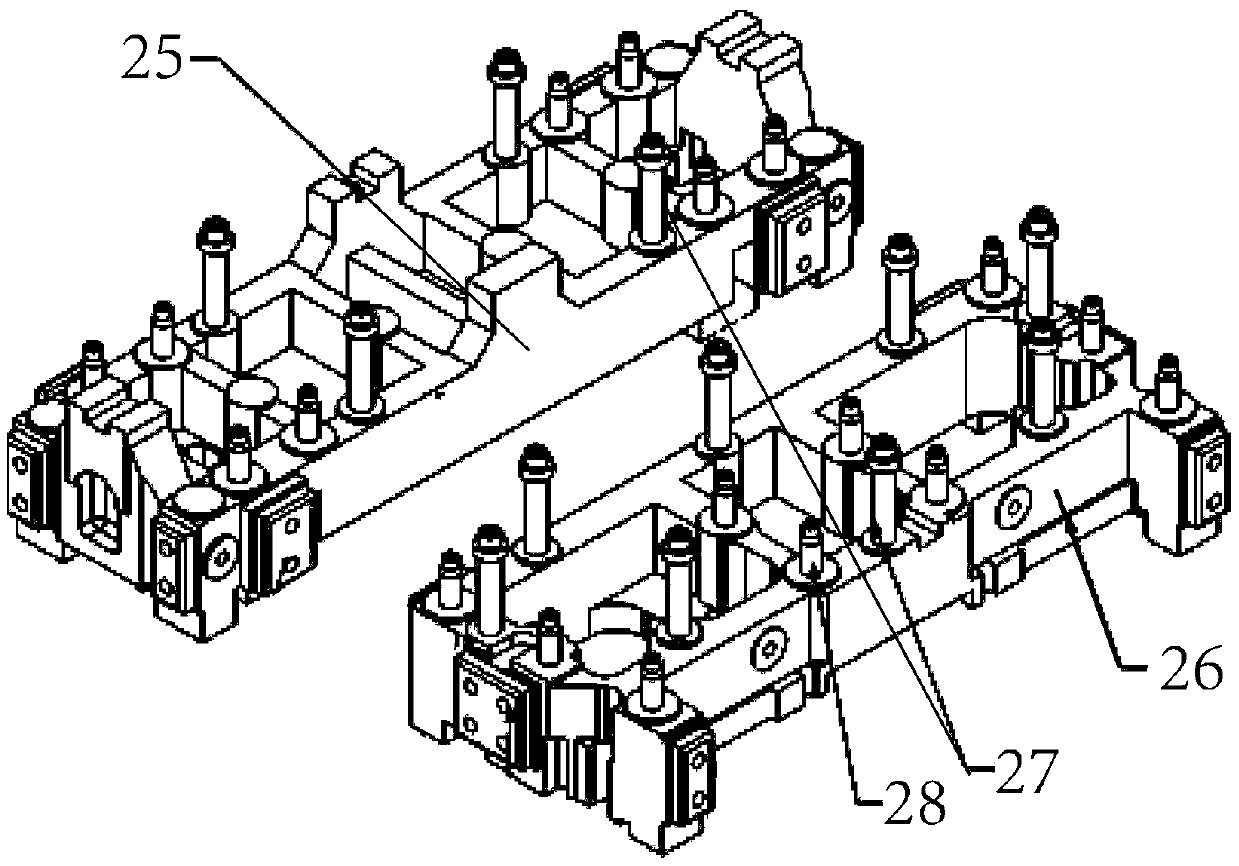

[0035] figure 1 It is a schematic diagram of the three-dimensional structure of the lower mold body in the present invention, figure 2 It is a schematic diagram of the three-dimensional structure of the upper mold body in the present invention, image 3 It is a schematic diagram of the three-dimensional structure of the two pressing core boards in the present invention. Such as figure 1 , figure 2 and image 3The rear connecting beam trimming punching die for a panoramic sunroof shown includes: a lower die body 1, a guide column 2, a travel limit block 3, a positioning key 4, a lifting rod 5, a first lower die insert 6, The second lower mold insert 7, slide frame 8, slide plate 9, slide plate support seat 10, balance pad 11, waste chute plate 12, polyurethane shock absorber 13, side limit block 14, waste slide Groove 15, upper mold body 16, first upper mold insert 17, second upper mold insert 18, third upper mold insert 19, fourth upper mold insert 20, side positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com