Printing system

A technology for printing systems and printing machines, applied to printing, printing machines, general parts of printing machinery, etc., can solve problems such as time-consuming, and achieve the effect of shortening the lost time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] One embodiment of the printing system of the present invention will be described below with reference to the drawings.

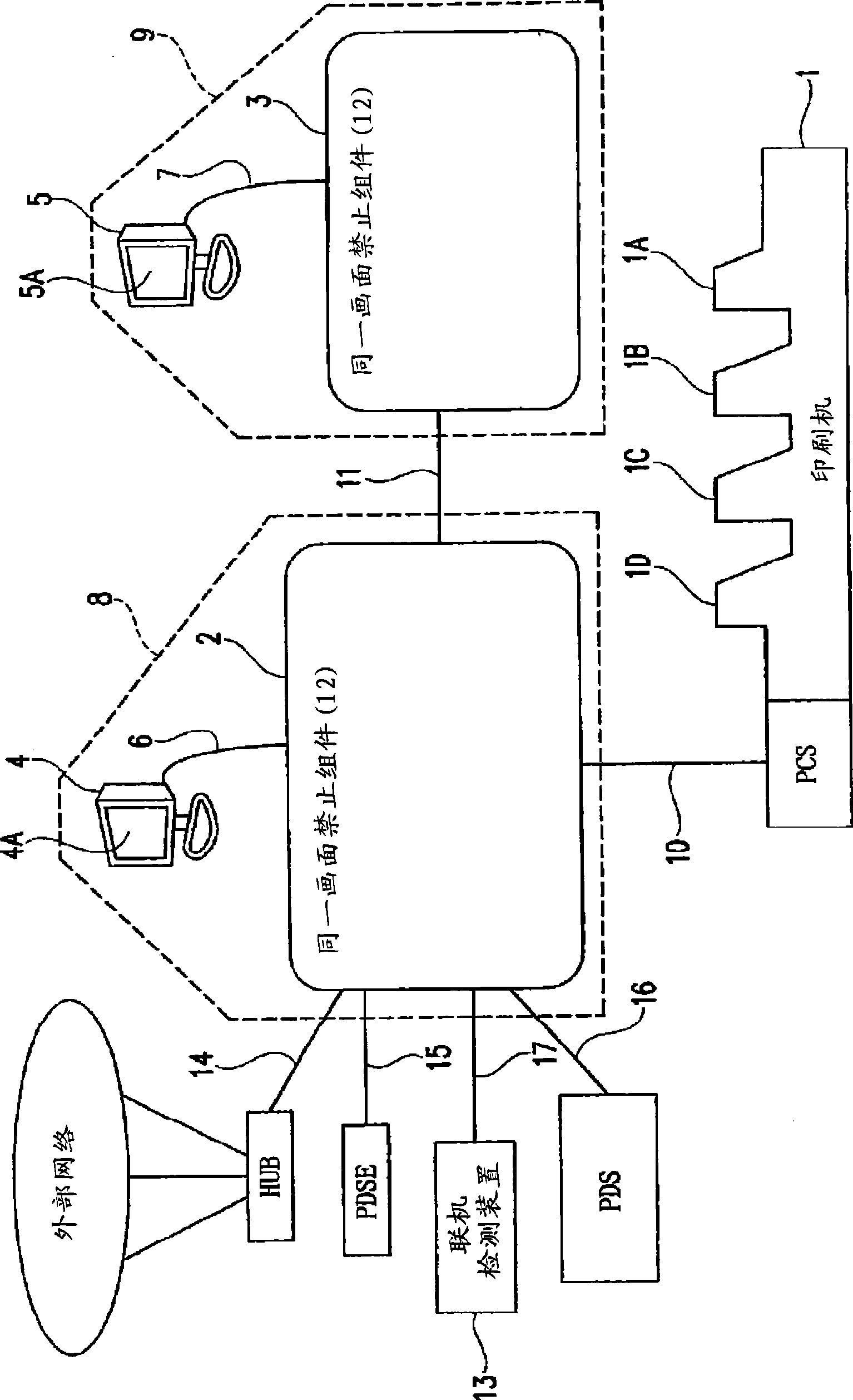

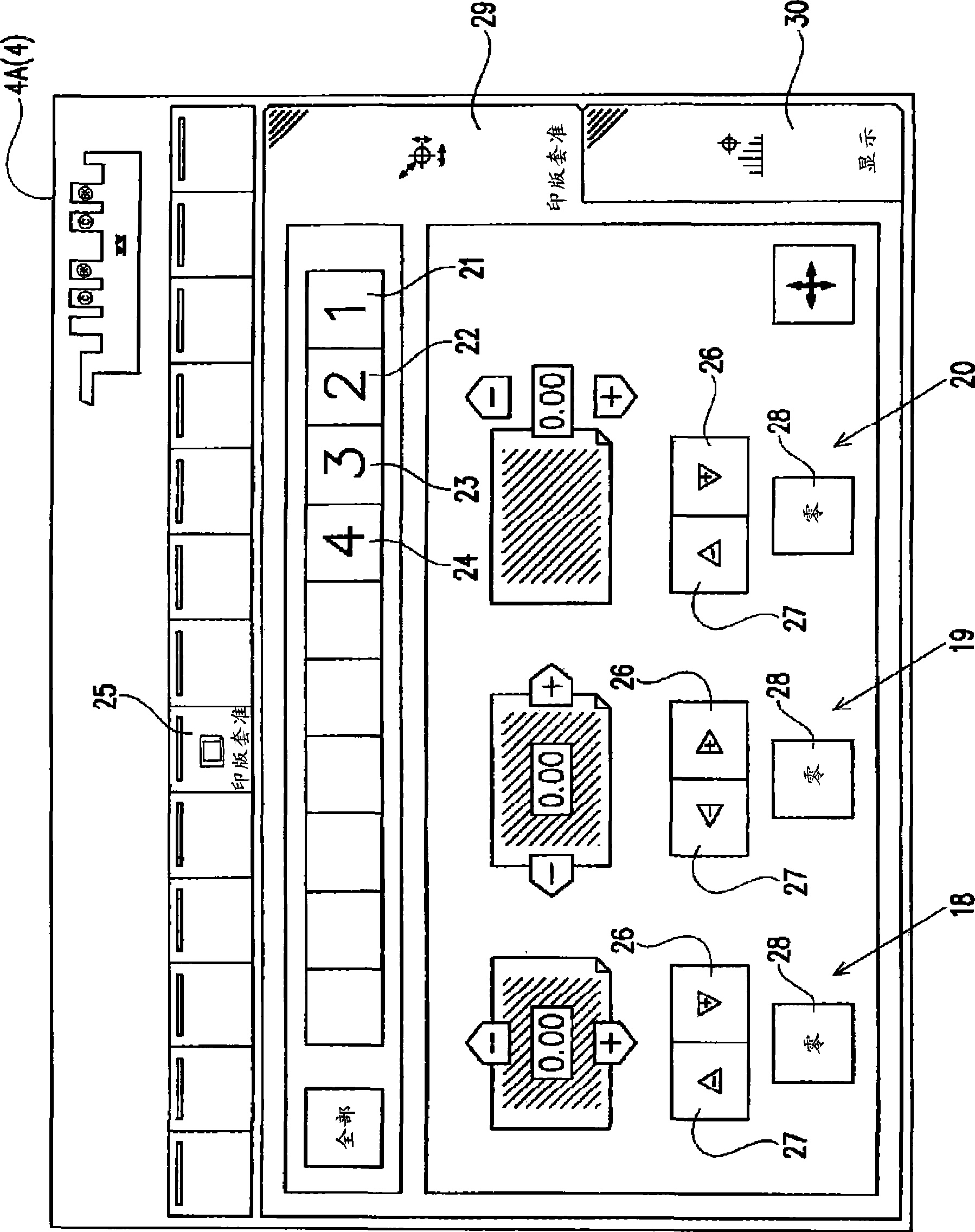

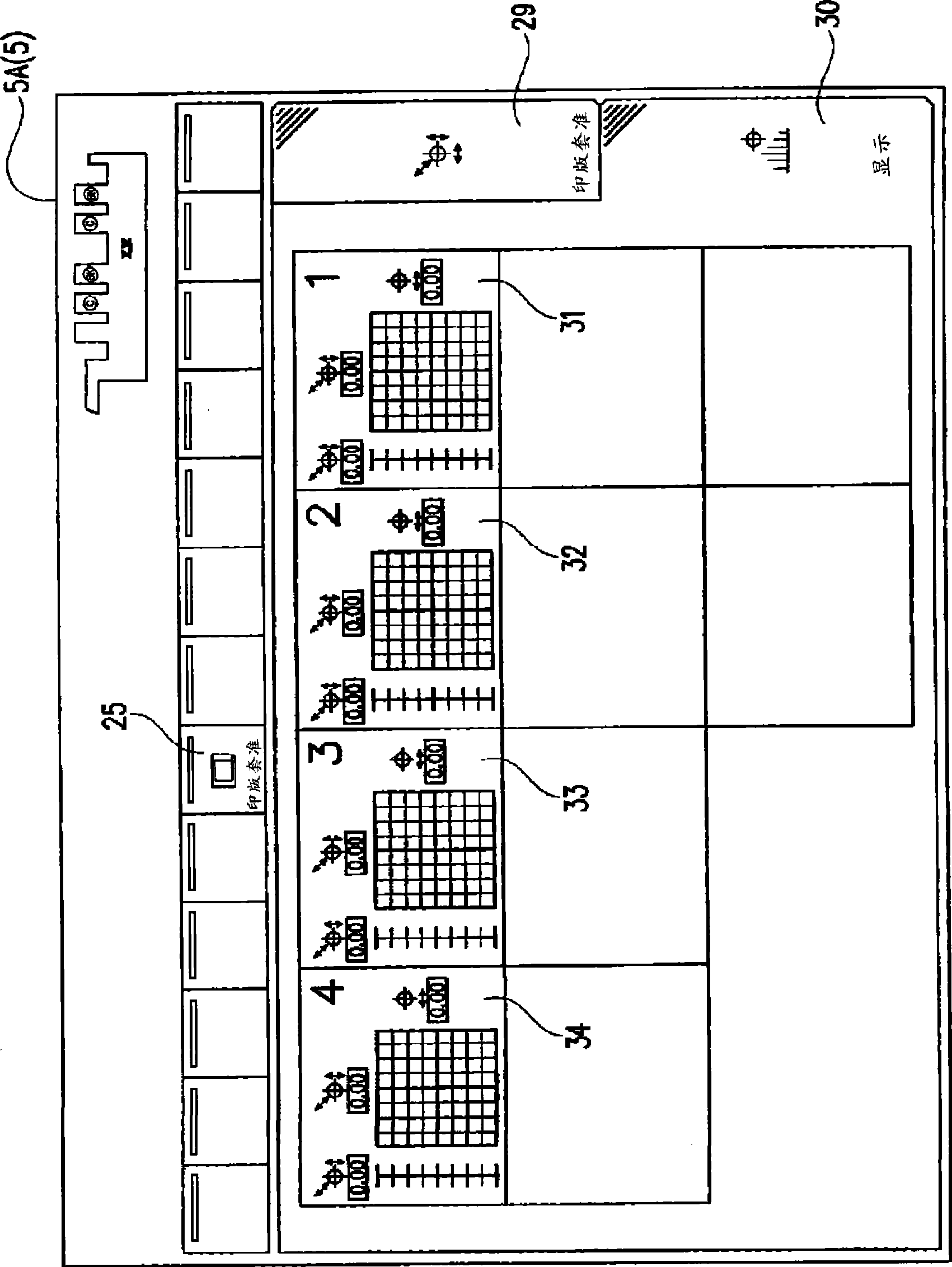

[0030] Such as figure 1 As shown, the printing system includes: a first input unit 2 and a second input unit 3, which are two input units for setting or changing the operating conditions (operating conditions) of the printing machine 1 for printing on paper; The first display 4 of a display unit and the second display 5 as a second display unit are used to display a screen representing the operation status of the printing machine 1 and an input screen for setting or changing the operation condition, wherein the The printing machine 1 operates according to the set or changed operating conditions. exist figure 1 An example in which the printing machine 1 is a perfecting printing machine having four printing units 1A, 1B, 1C, 1D to print two colors of black (Bk) and cyan (C) is shown in After the surface of the paper, two colors of black (Bk) and cyan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com