Temperature control case for lithium battery bag

A lithium battery and casing technology, which is applied in the field of lithium battery pack temperature control casing, can solve the problems of high working voltage, poor effect, and drop in battery surface temperature, and achieve the effect of simple structure and good temperature control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

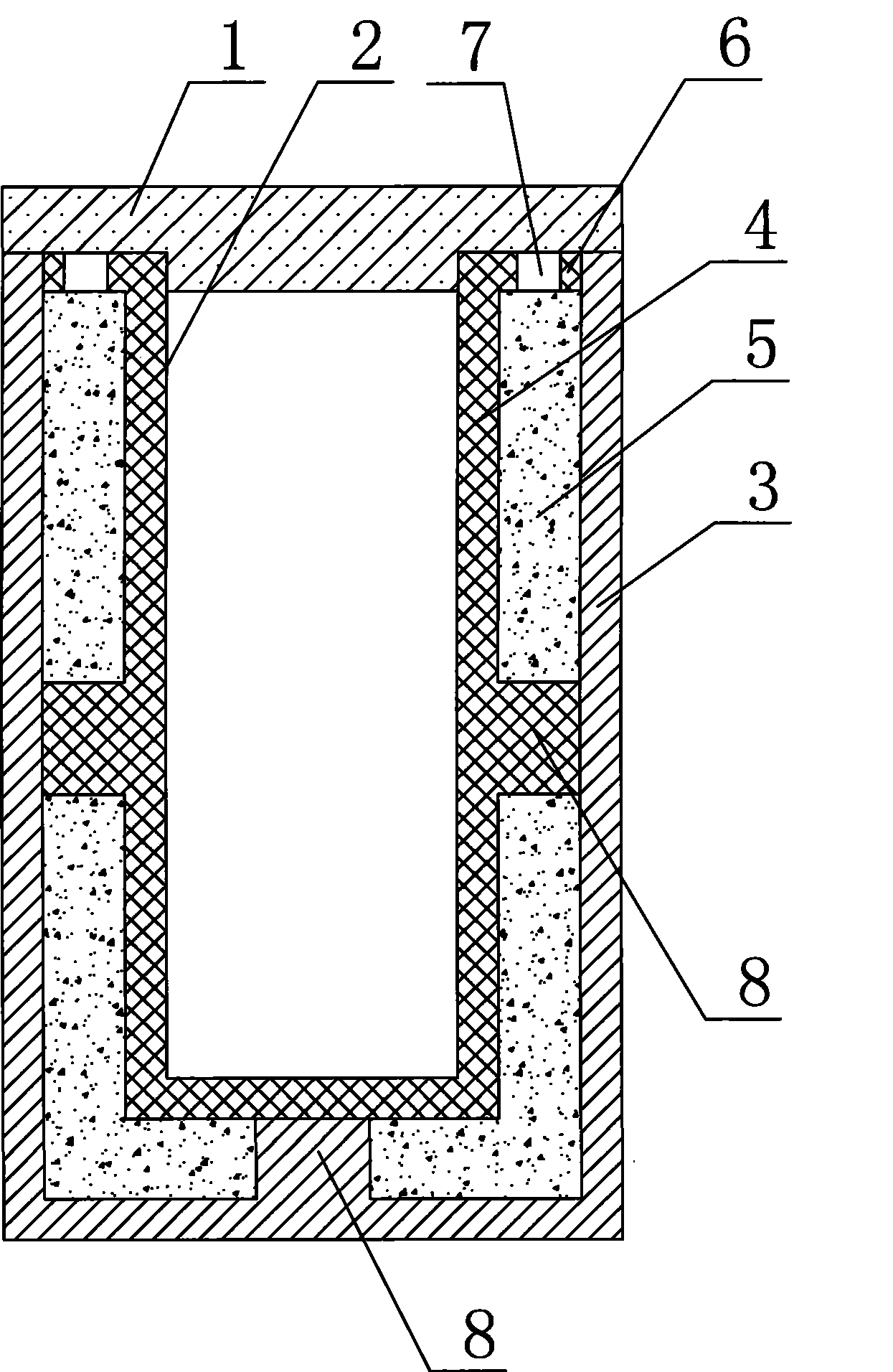

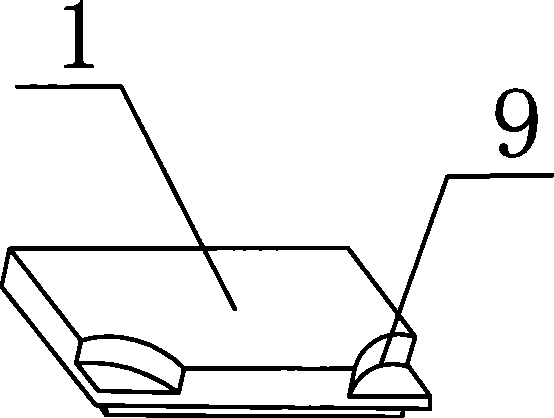

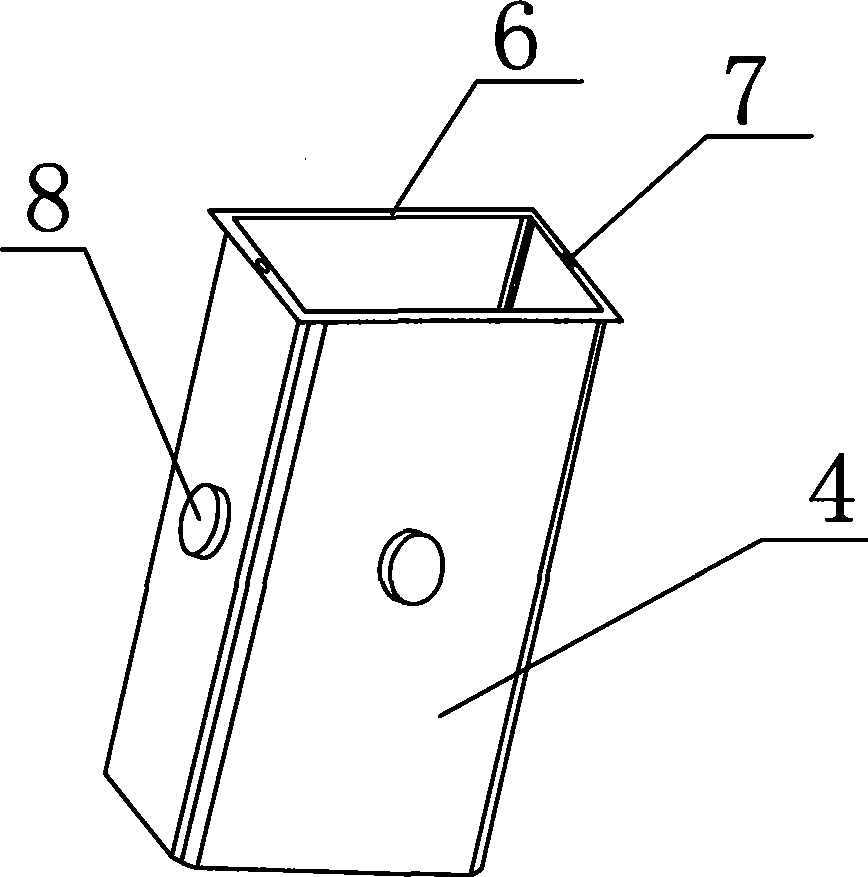

[0017] Such as Figure 1 to Figure 4 , a lithium battery pack temperature control casing, including a casing 2, a cover plate 1 arranged at the opening of the casing 2, the casing 2 includes a casing outer layer 3 and a casing inner layer 4, the casing outer layer 3 and the casing inner layer 4 The shell inner layers 4 are connected to each other to form a cavity. A phase change material layer 5 is arranged in the cavity. A partition 6 is provided at the opening of the inner layer 4 of the housing, and a material injection hole 7 is provided on the partition 6 . The phase change material is injected into the cavity by using the injection hole 7 for temperature control. A spacer 8 is provided on the outer center of each side wall of the shell inner layer 4 , and the thickness of the spacer 8 is the same as the width of the spacer 6 . A spacer 8 is provided on the inner wall at the bottom end of the shell outer layer 3 . The shell inner layer 4 and the shell outer layer 3 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com