Self-regulating levitation wind power generation system

A wind power generation system and self-adjusting technology, which is applied in the direction of wind power generation, wind power engine, wind power motor combination, etc., can solve problems such as insufficiency, and achieve the effect of high power generation efficiency, large moment of inertia, and small maintenance workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

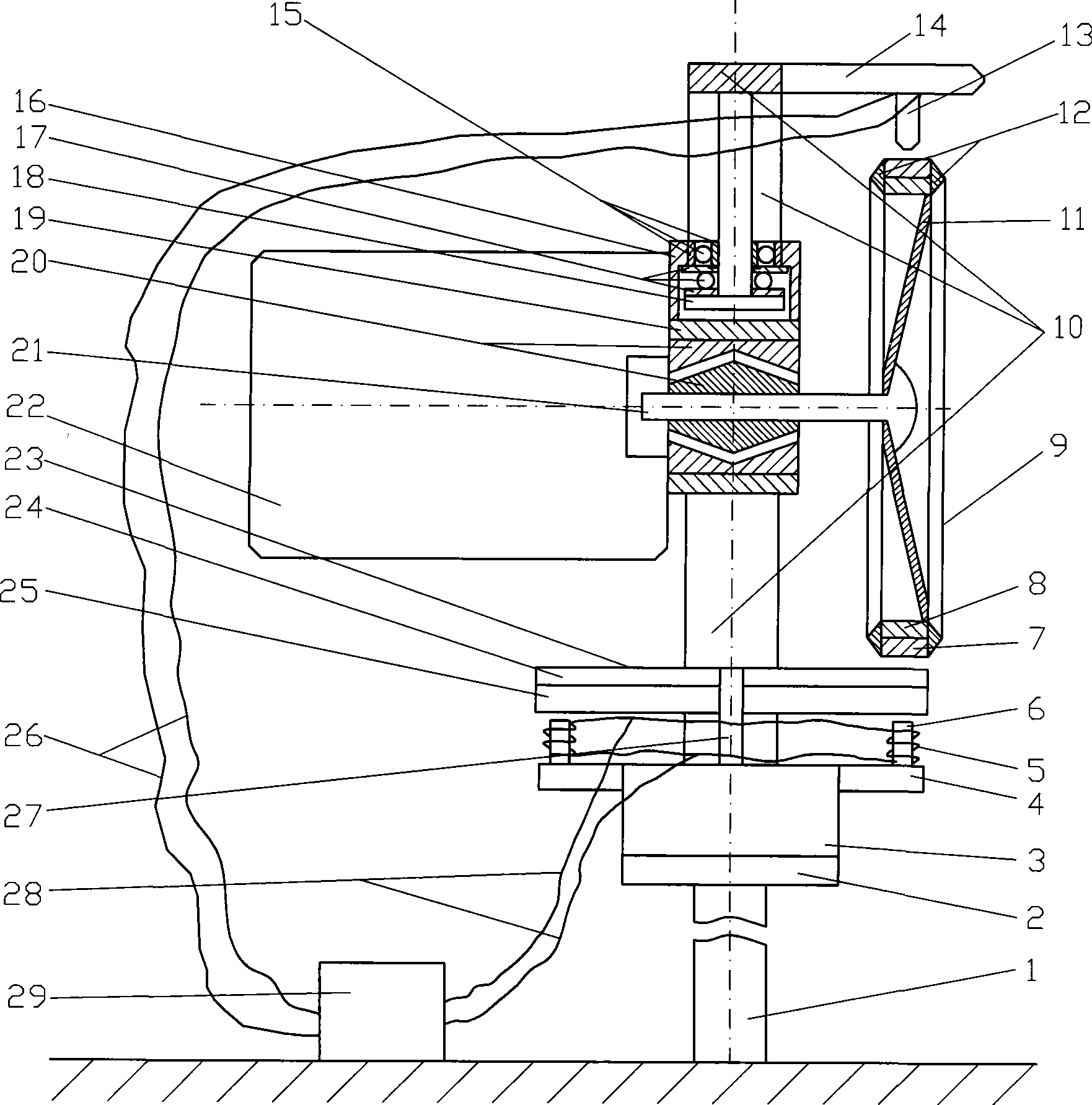

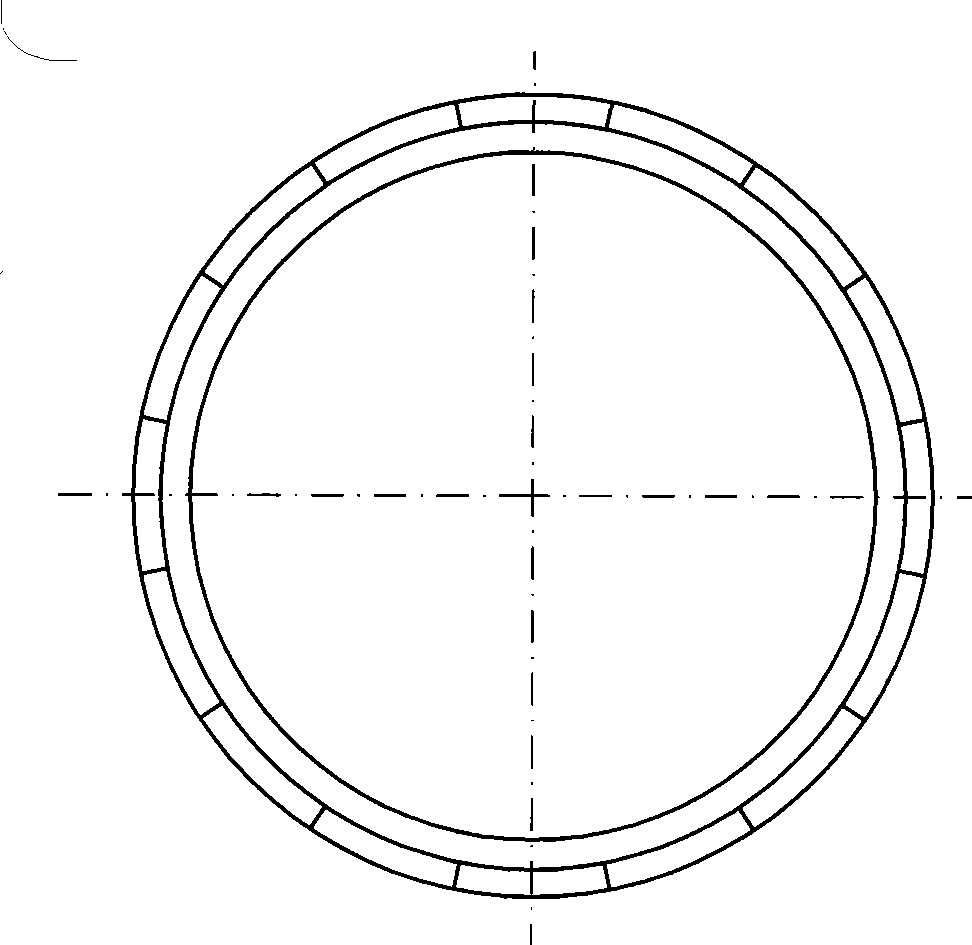

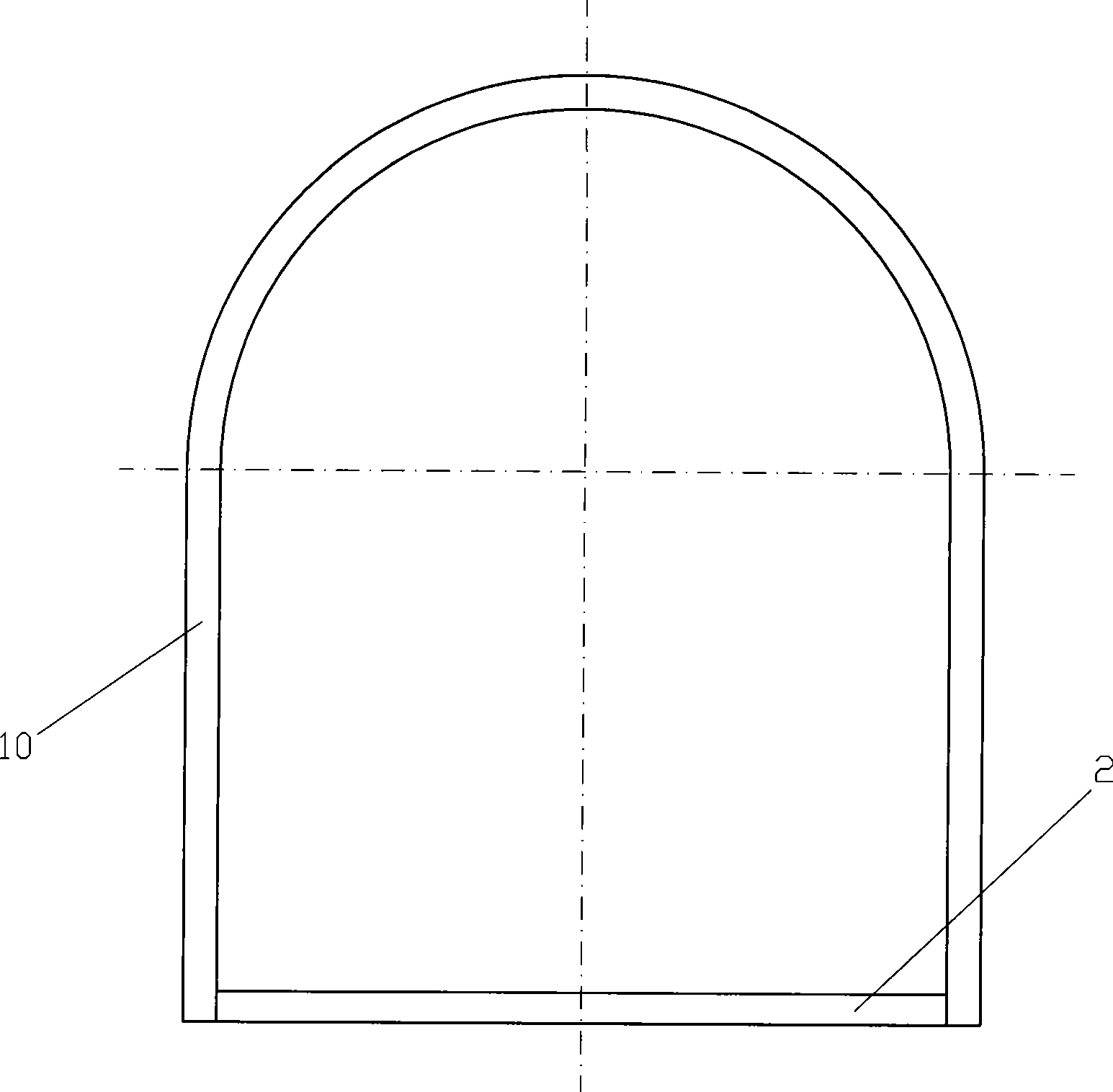

[0026] Embodiment one: if Figure 1 to Figure 7 Shown, the supporting plate 2 is fixed on the top of the column 1 fixed on the foundation, the generator 3 is fixed on the supporting plate 2, and the rotor shaft 27 of the generator 3 is supported by a magnetic suspension bearing (not shown in the figure); The outer circle of the upper part is socketed with the disk 4, and some electromagnets 6 are vertically fixed on its upper end face, all of the electromagnets 6 are on the same circle, and the coil 5 of the electromagnet 6 is connected to the power output terminal of the controller 29 with a wire 28; The upper end of the rotor shaft 27 is fixed to the axially magnetized permanent magnetic disk 24 and induction disk 25 sequentially in the axial direction, the permanent magnetic disk 24 and the induction disk 25 form the transmission disk 23, and the lower end surface of the induction disk 25 is parallel to the upper end surface of the electromagnet 6. A gap; the arched ring 10 ...

Embodiment 2

[0027] Embodiment two: if Figure 8 Figure 9 As shown, the following changes are made to Embodiment 1. The permanent magnetic coil 7 and the collar 8 of the wind wheel 9 can also be replaced by a radially magnetized permanent magnetic coil 35, and the permanent magnetic disc 24 of the transmission disc 23 is replaced by a permanent magnetic disc 33. The magnetic disk 33 is made up of a number of sector-shaped magnetic blocks that are magnetized alternately along the axial polarity or by a permanent magnetic disk partitioned along the circumferential direction and alternately magnetized along the axial polarity, and fixed on the bottom surface of the permanent magnetic disk 33 along the axial direction Magnetic disc 32, induction disc 31; pick bar 34 is fixed on the lower part of arched ring 10, speed measuring sensor 13 is installed on the pick bar 34, and the head of sensor 13 faces the limit portion of the upper end surface of permanent magnetic disc 33 and leaves a gap , ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap