Ironing apparatus

A technology of ironing equipment and equipment, applied in the direction of hand irons, textiles and papermaking, household appliances, etc., can solve the problems of incomplete evaporation of water, low sealing and steam delivery pressure, increased production cost and energy consumption, etc., to improve energy efficiency. The effect of reducing consumption and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

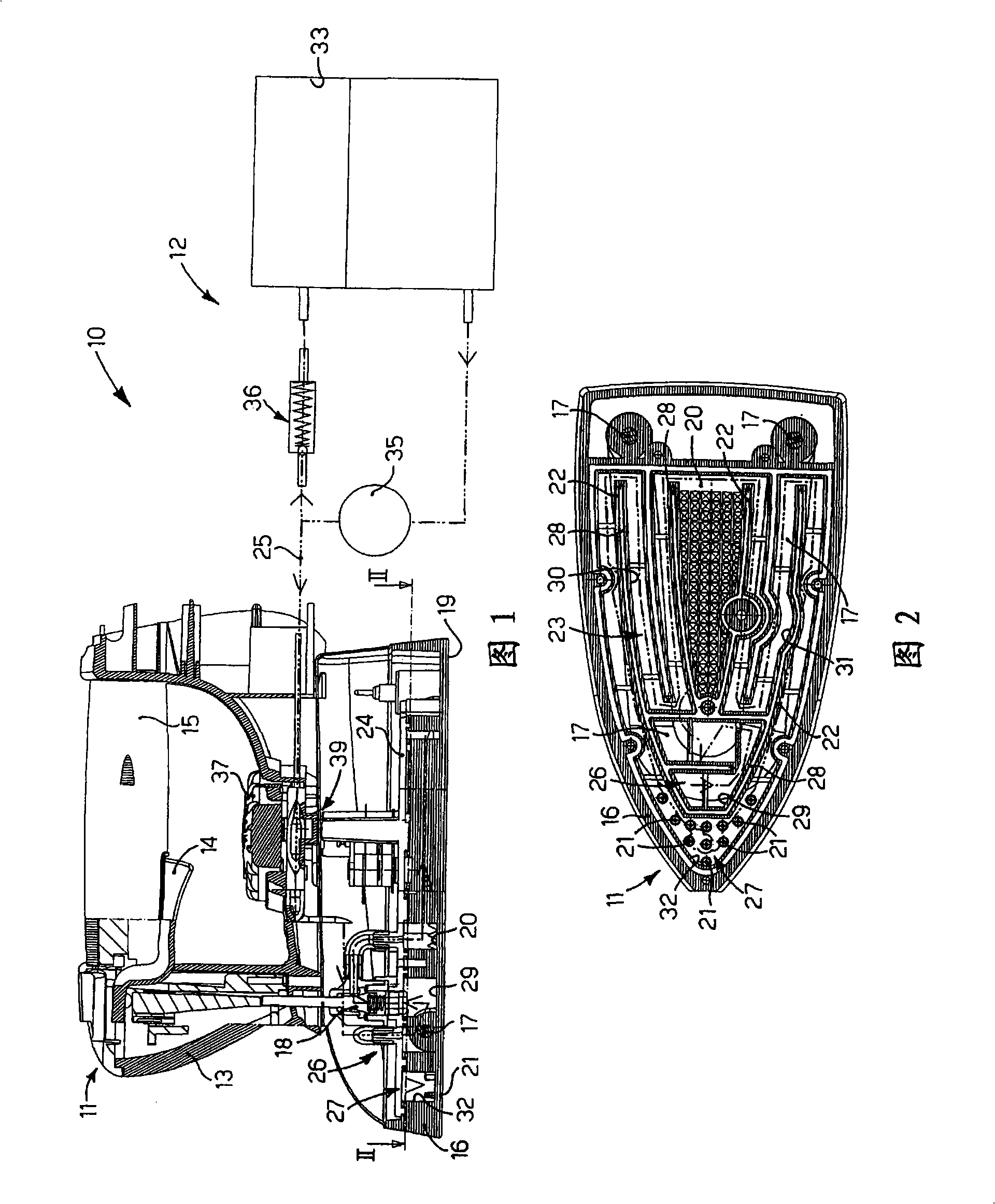

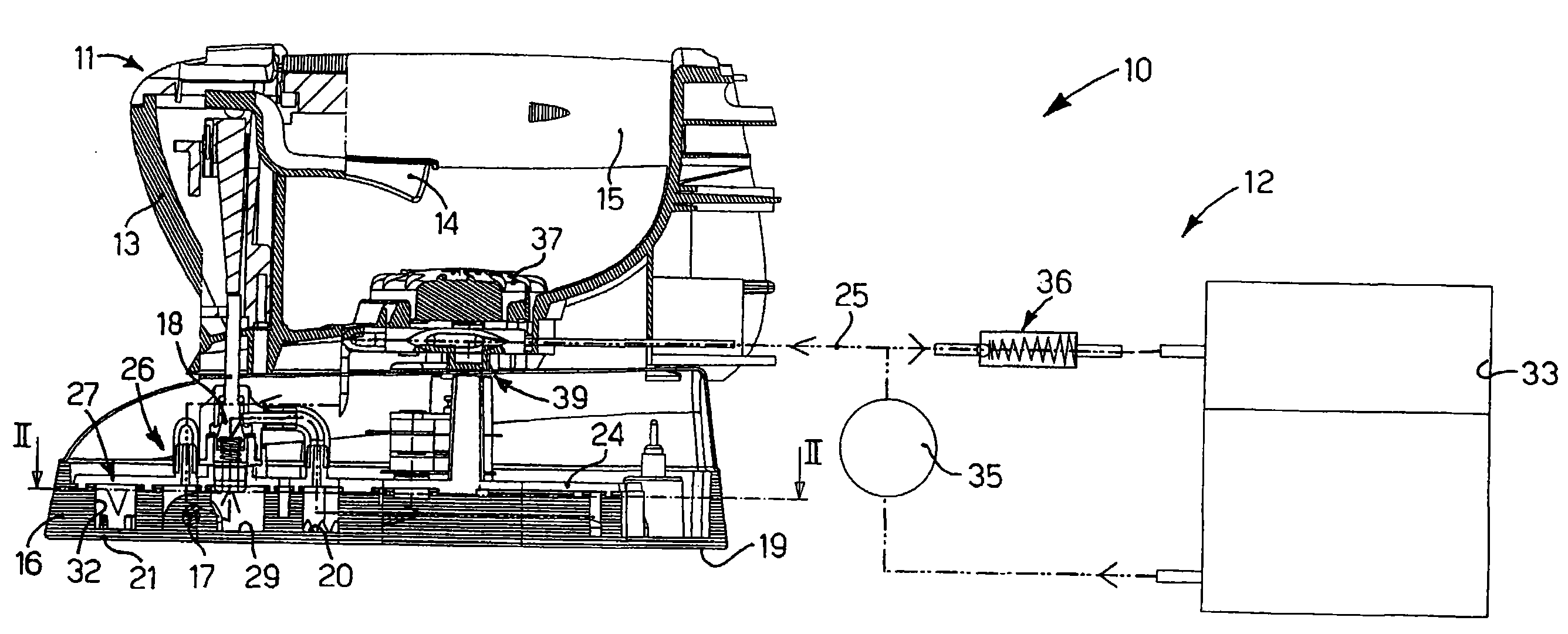

[0036] Referring to the accompanying drawings, an ironing appliance 10 according to the invention basically comprises an iron 11 and a container unit or tank 12 for water, which in this particular case is arranged outside the iron 11 .

[0037] In particular, the iron 11 is of the steam type and comprises a central body 13 having in the upper part a grip handle 15 on which is mounted a button 14 for selectively delivering steam superior. The central body 13 is connected in the lower part with an ironing board 16 which is processed into a pointed shape and made of metal material.

[0038] The central body 13 is of essentially conventional type and is connected to the tank 12 by means of a pipe 25 only schematically shown in FIG.

[0039] The central body 13 also includes a valve 18, which is arranged downstream of the inlet area 26 and is mechanically connected to a button 14 which, when suitably actuated, enables the water inside the ironing board 16 to selectively By constr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com