Transfer printing device for cold-transfer decorating machines

A technology of cold transfer printing and cooling device, used in printing presses, transfer printing, rotary printing presses, etc., can solve the problems of short printing time and unstable printing pressure, and achieve increased transfer printing time, long transfer printing time, Guaranteed effect of transfer printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

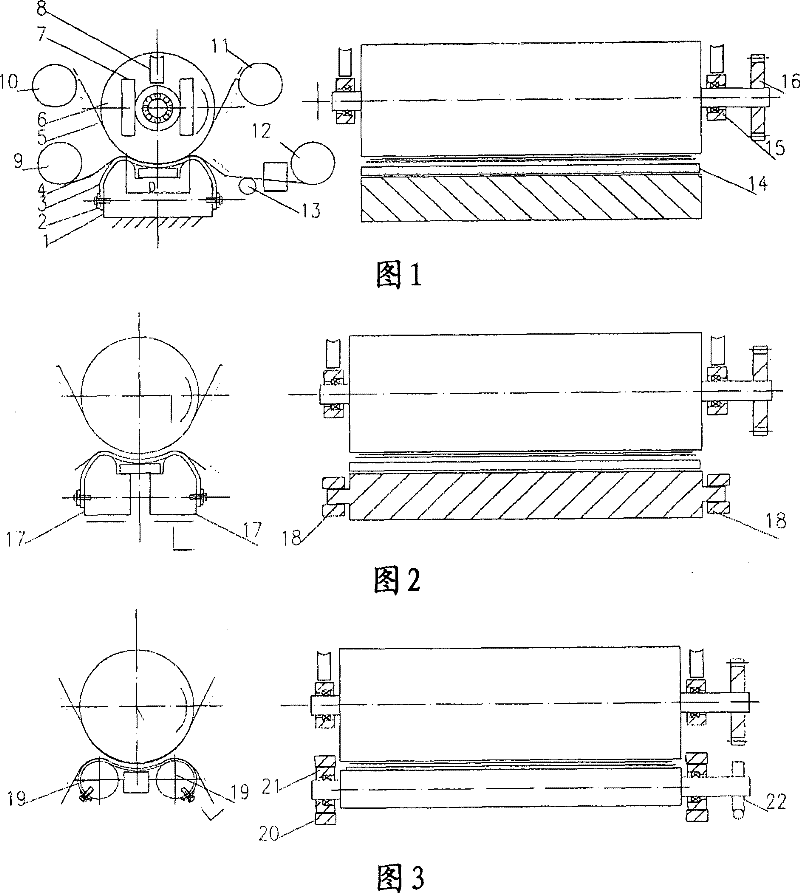

[0034] The transfer device of the cold transfer printing machine.

[0035] See figure 1 Shown: The transfer device of the cold transfer printing machine is located in the middle of the transfer printing machine, including mechanical parts such as the base, fixed splint, transfer belt, transfer roller, pressure device, cooling device, bearing seat and drive wheel. The transfer device of this cold transfer printing machine is composed of a transfer roller 6 , a transfer belt 3 , a cooling device 14 and a base 1 connected from top to bottom. In this embodiment, the base 1 is a one-piece concave rigid recess. Base 1 is fixed on the frame. The transfer roller 6 is a circular roller, the two ends of the central axis of the transfer roller are supported by bearings and bearing housings 15 and connected with the pressurizing device 8, and a cold transfer printing machine is installed next to the bearing at one end of the central axis. The transmission wheel 16 that transmission mec...

Embodiment 2

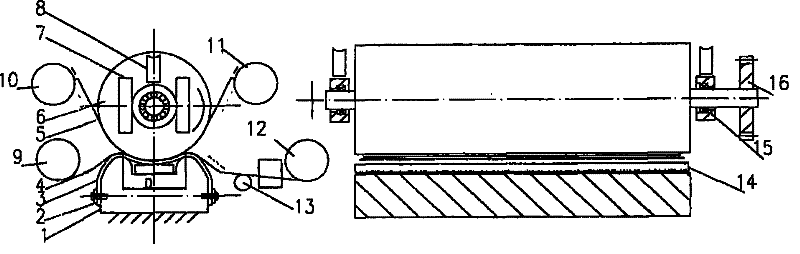

[0038] Transfer printing mechanism of variant A.

[0039] See figure 2 Shown: its principle and concrete implementation are identical except that base form is different, other structures are identical with embodiment 1. The difference is figure 1 Change the original transfer belt base 1 in figure 2 The two transfer belt installation bases 17, the base 17 can be moved on the sliding seat 18 and can be locked, the advantage of this is that the position of the transfer belt installation base 17 can be adjusted in the horizontal direction according to the needs, that is, the pressure can be adjusted. At the same time, the parallelism between the transfer belt 3 and the transfer roller 6 can also be adjusted, that is, the uniformity of the printing pressure can be adjusted. The advantage of the transfer printing mechanism of modification A is that it can not only adjust the pressure of the transfer roller on the transfer belt, but also adjust the size of the matching surface o...

Embodiment 3

[0041] Transfer printing mechanism of variant B.

[0042] See image 3 Shown: its principle and concrete implementation are identical except that base is different, other structure is identical with embodiment 1. The difference is figure 1 The original transfer belt base 1 is changed into two transfer belt installation rollers 19, and the two ends of the transfer belt installation rollers 19 are equipped with bearings 21, bearing seats 20 and locking mechanisms 22 that can rotate and lock them. At least one transfer belt mounting roller 19 is rotatable. The advantage of this is that the locking mechanism can be opened as required and the transfer belt mounting roller 19 can be turned to adjust the length of the wrapping surface on the transfer belt 3 and the transfer roller 6, that is, adjust the size of the transfer printing area, and can also transfer at any time. Parallelism adjustment with 3 to ensure the uniformity of printing pressure. The advantage of the transfer p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com