Adjustable combined detacher

A disassembler and adjustable technology, which is applied in the field of tools, can solve the problems that the disassembler cannot be well adapted to disassembly operations, the size, shape and position of circular parts are very different, and disassembly is difficult

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

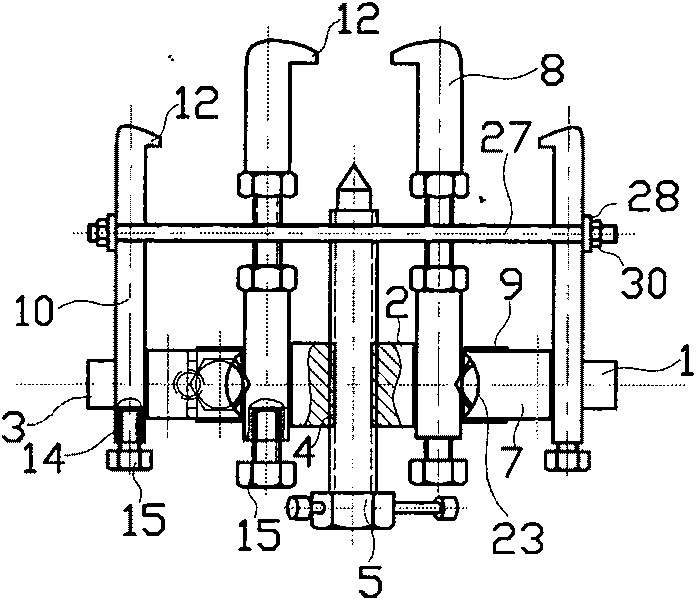

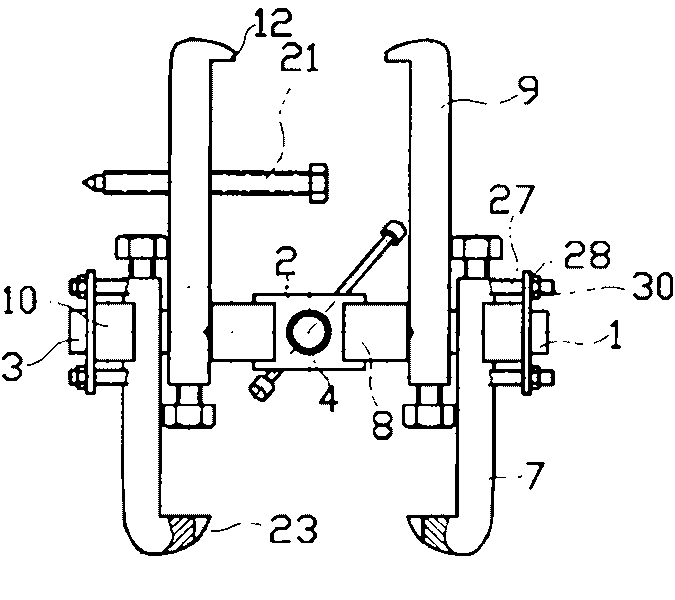

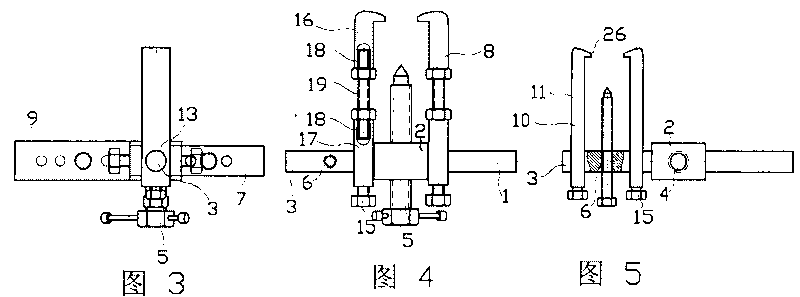

[0022] Figure 1 to Figure 10 Among them, the adjustable combined detacher has a three-stage stepped round rod arm 1, and the round rod arm has a middle segment arm 2 and two side arms 3. The outer diameter of the middle segment arm is larger, and the length and outer diameter of the two side arms are equal. There is a radial through hole, which is the middle through hole 4. There is an internal thread in the middle through hole, and the main thread ejector rod 5 is rotated in the middle through hole. There is a radial through hole in the middle of a side arm, which is the side through hole 6. There are internal threads in the through hole, and four pairs of pull hooks are symmetrically set on the arms on both sides. The four pairs of pull hooks are respectively arc claw pull hook 7, variable rod pull hook 8, removal rod body pull hook 9 and short pull hook 10. The pull hook has a straight rod body 11, The front end of the rod body has a claw 12 bent to one side, and the rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com