Heat-variable surface shearing stress sensor

A shear stress and sensor technology, applied in the field of micro-electromechanical systems, can solve the problem of not being able to obtain surface shear stress at the same time, and achieve the effect of improving time and space resolution and realizing miniaturization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

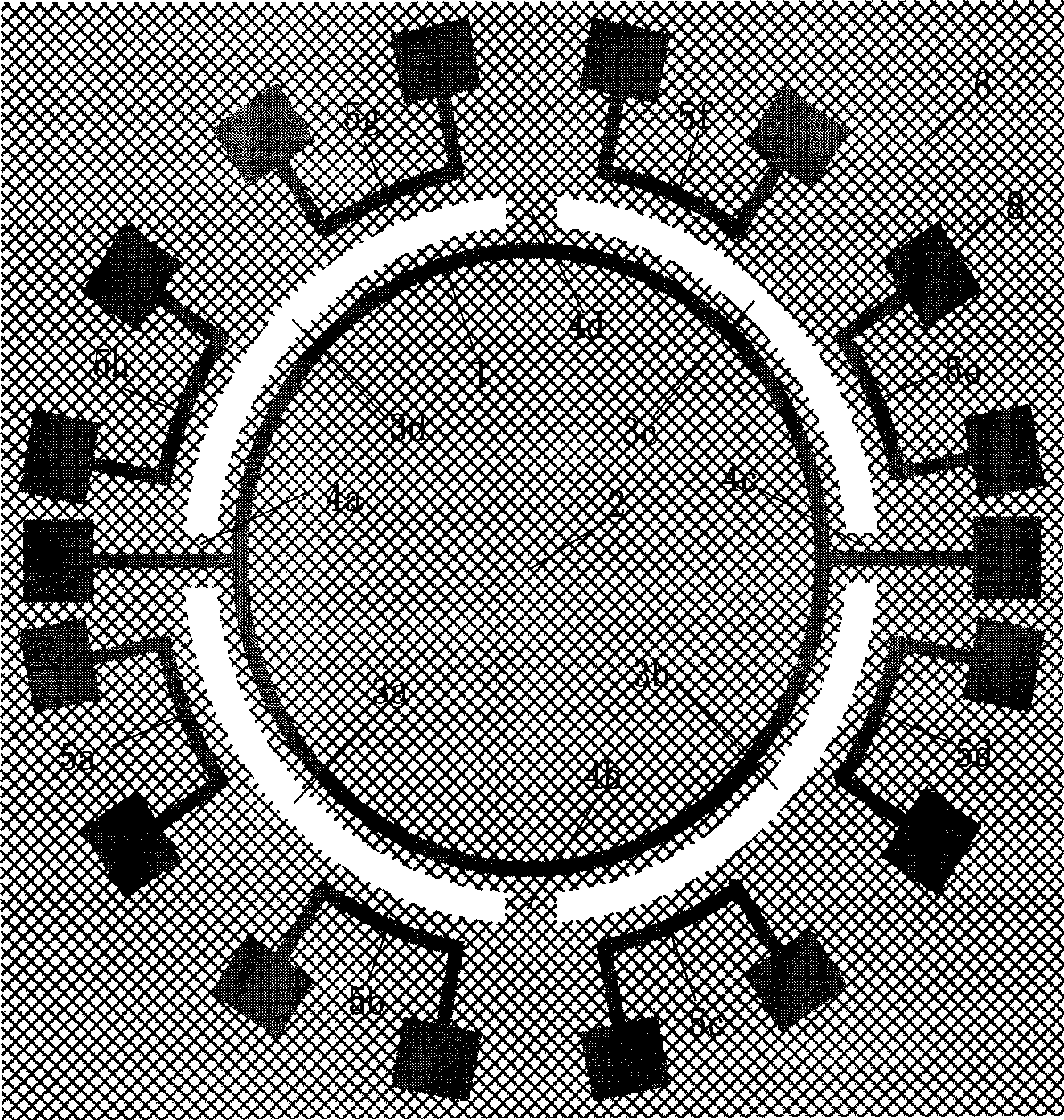

[0015] combine image 3 and Figure 4 , the thermosensitive surface shear stress sensor of the present invention includes a heating / thermosensitive coil 1, a support film 2, heat insulation grooves 3a, 3b, 3c, 3d, support beams 4a, 4b, 4c, 4d, and thermosensitive electrodes 5a, 5b , 5c, 5d, 5e, 5f, 5g, 5h, an electrical insulating film 6, a silicon substrate 7 and a lead electrode 8, forming a support film 2 and an electrical insulating film 6 by depositing on the surface of the silicon substrate 7, the The substrate under the support film 2 is etched away, and supports the heating / thermosensitive coil 1; the support film 2 and the electrical insulation film 6 are connected by support beams 4a, 4b, 4c, 4d, and the electrical insulation film Prepare thermosensitive electrodes 5a, 5b, 5c, 5d, 5e, 5f, 5g, 5h on 6, and the thermosensitive electrodes 5a, 5b, 5c, 5d, 5e, 5f, 5g, 5h are evenly distributed in the heating / thermal The outer edge of the sensitive coil 1 is a thermal in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com