Permanent magnet type DC motor assembly

A technology for motors and components, applied in the direction of electric components, magnetic circuit rotating parts, electrical components, etc., to achieve the effect of enhanced meshing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

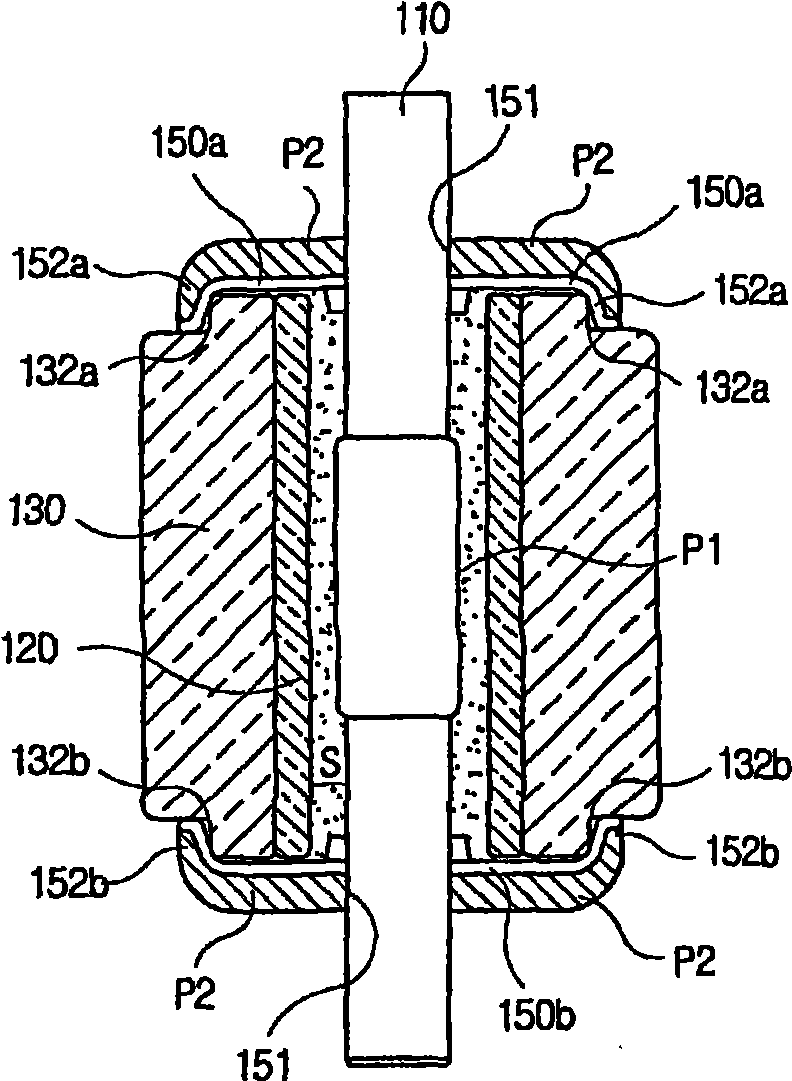

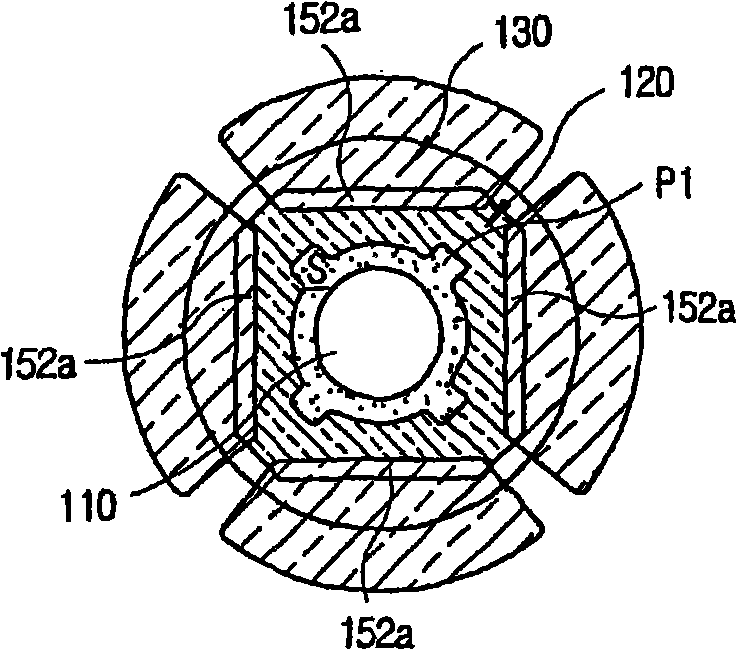

[0021] figure 2 and image 3 A cross-sectional view and a plan view of a DC motor assembly according to a preferred embodiment of the present invention are shown, respectively.

[0022] refer to figure 2 and image 3 , the DC motor assembly includes a rotary shaft 110 for performing rotary motion, a cylindrical rotor core 120 surrounding the rotary shaft 110, a plurality of magnets 130 attached and arranged on the outer periphery of the rotor core 120, and at the same time on the rotor core A predetermined distance is maintained between the magnet 120 and the magnet 130 . The DC motor assembly also includes upper and lower cover plates 150a and 150b as fixing members for fixedly engaging the magnet 130 and the rotor core 120 with the rotary shaft 110 in a more reliable manner.

[0023] The rotation shaft 110 is disposed substantia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com